Here's how the Lid punching machine operates

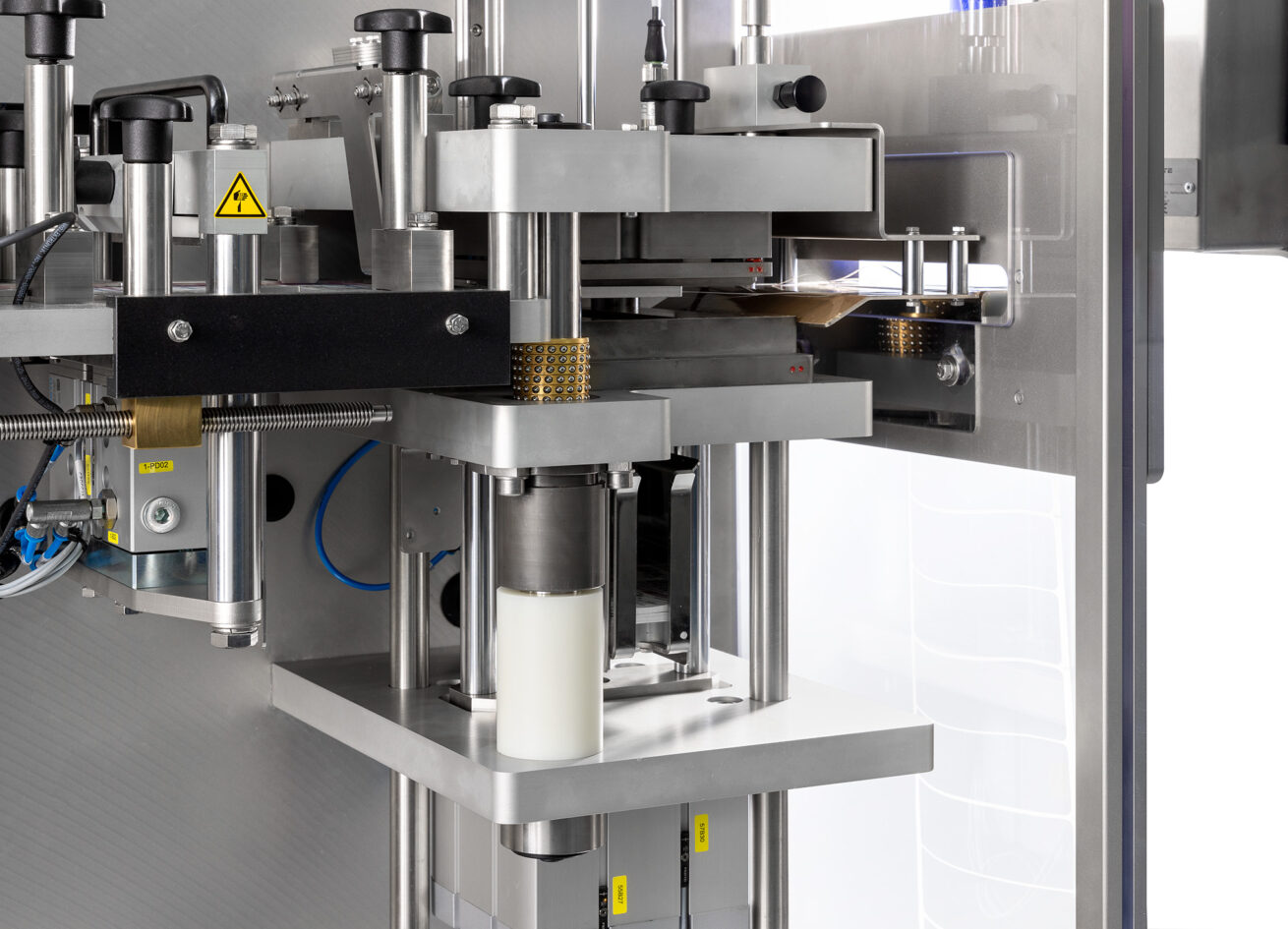

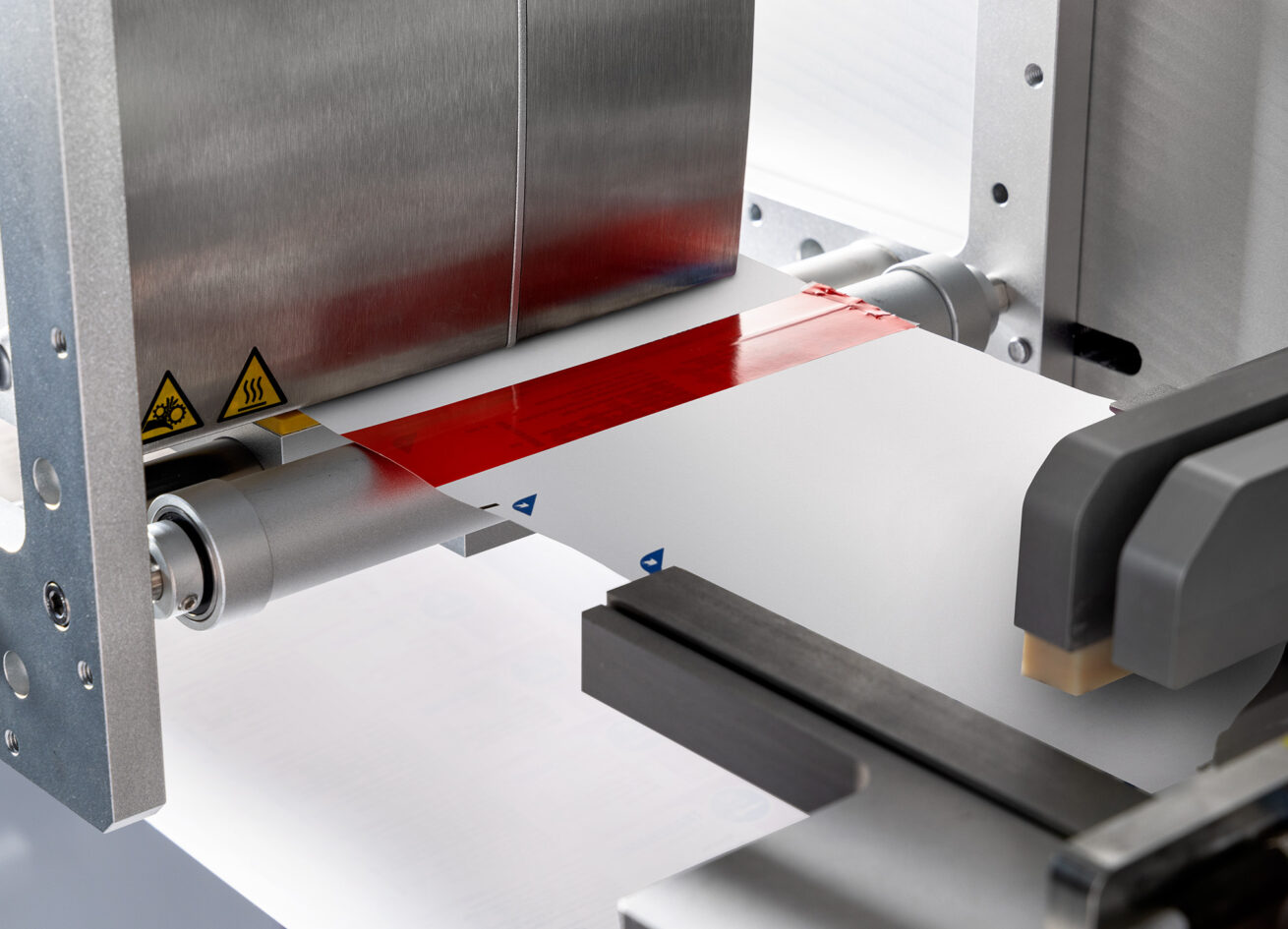

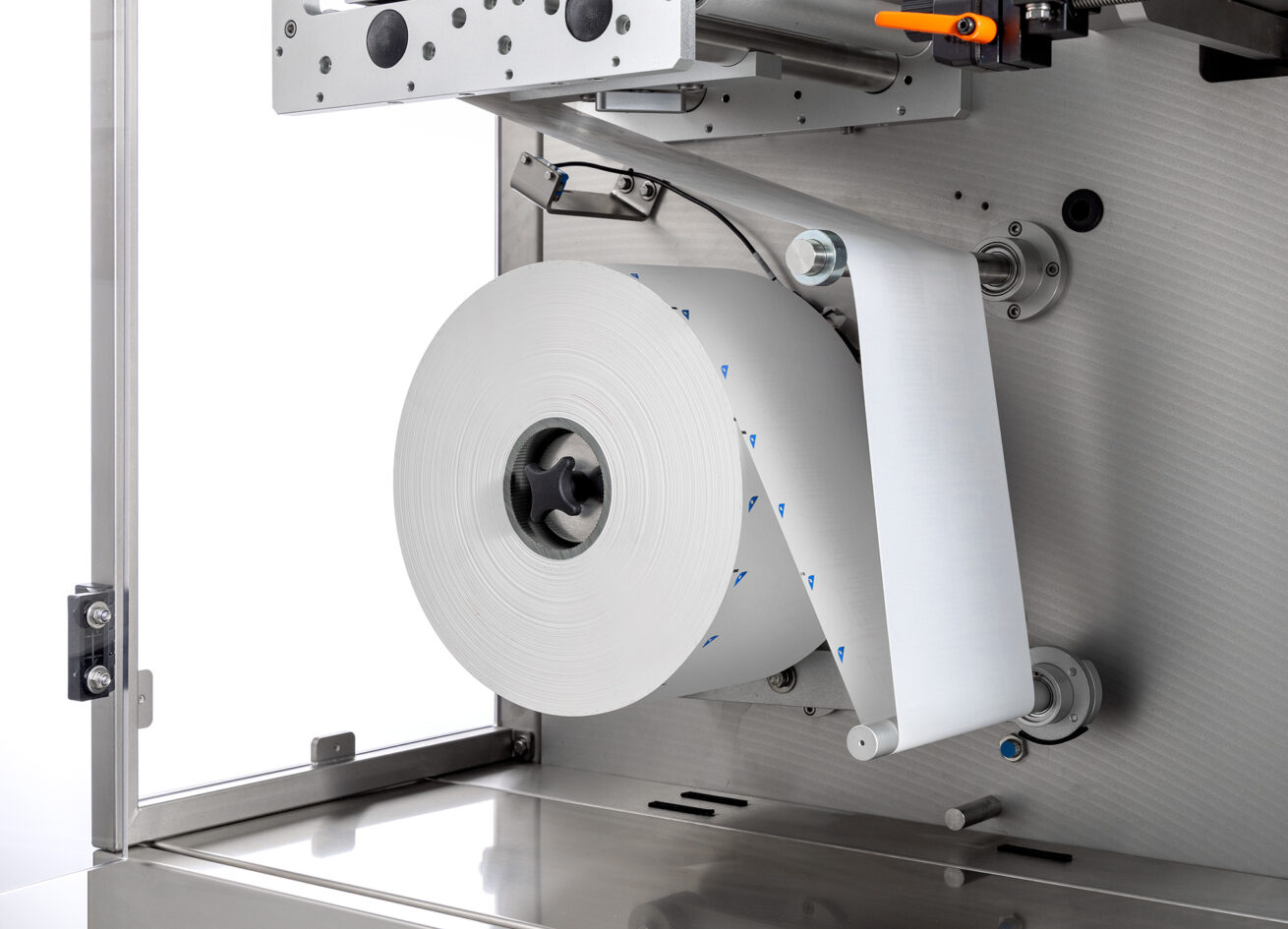

The paper is fed into the thermal transfer printer via an unwinding unit, where a lot number and best-before date are printed onto it. This step does not happen if the colour sensor detects coloured tape. If it does, the machine doesn’t print anything.

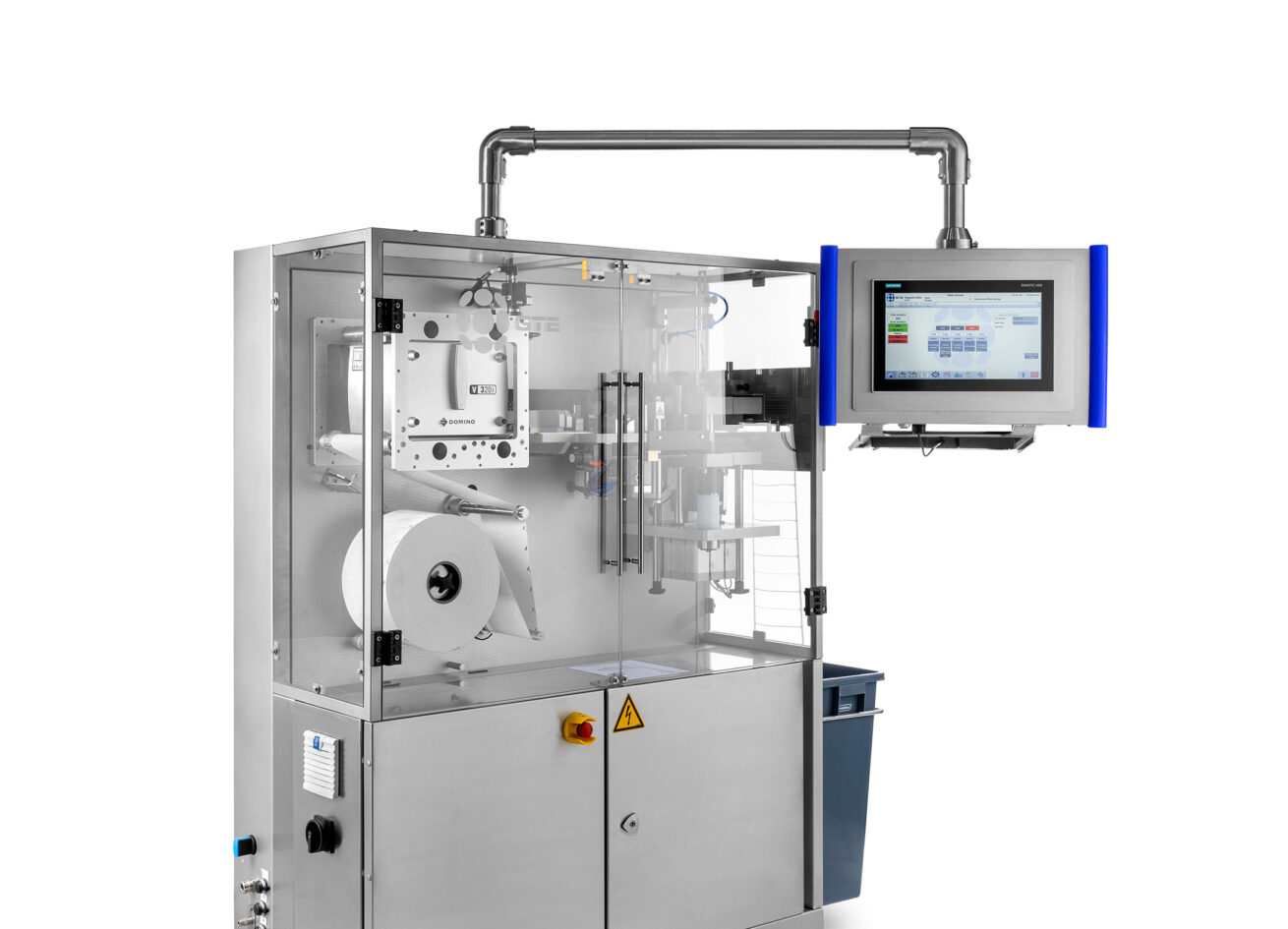

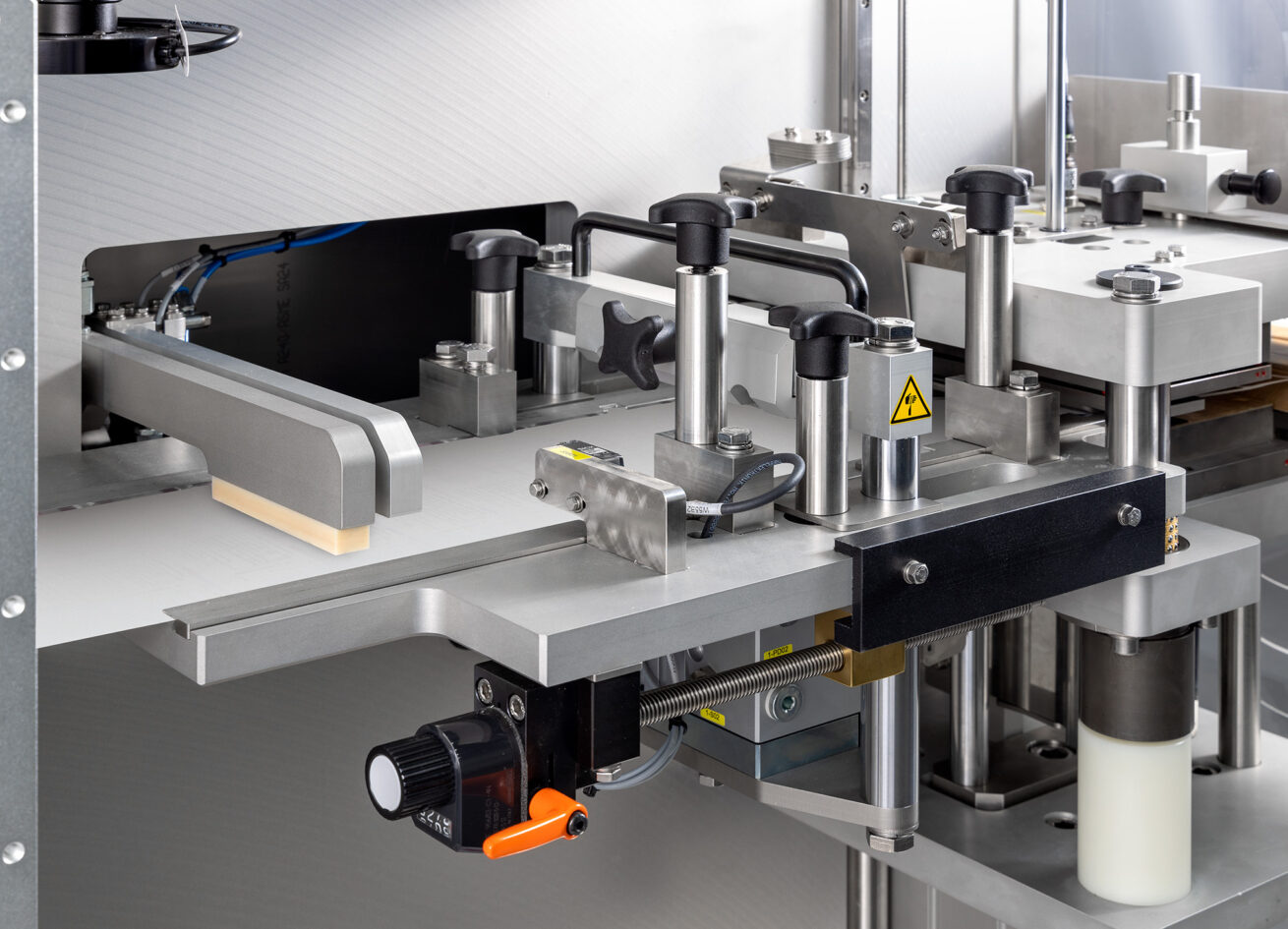

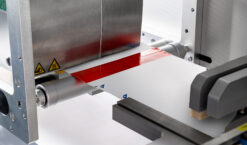

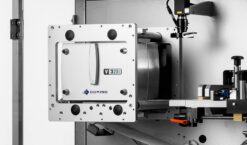

The lid then passes under a camera which checks if the lids contain the correct data and material codes. This Optical Character Recognition (OCR) check recognises the text and, based on that, makes the decision to punch the lid. If necessary, the lid is also perforated. Lids then enter the warehouse.

If a lid has been rejected by the Vision System or has coloured tape used to stick various rolls together, it is not punched out but sent to the waste bin together with the remnants of the roll. This process is called Splice detection.

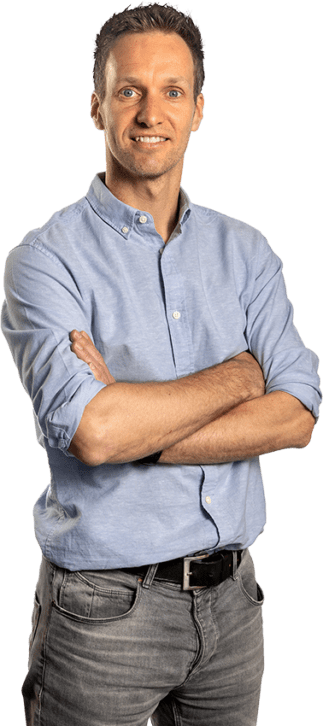

Specifications

- Total solution for punching, perforating, and printing

- Maximum diameter of 400 mm

- Comprehensive control system using Vision checks

- Great for high mix, low volume

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)