Folding and Gluing

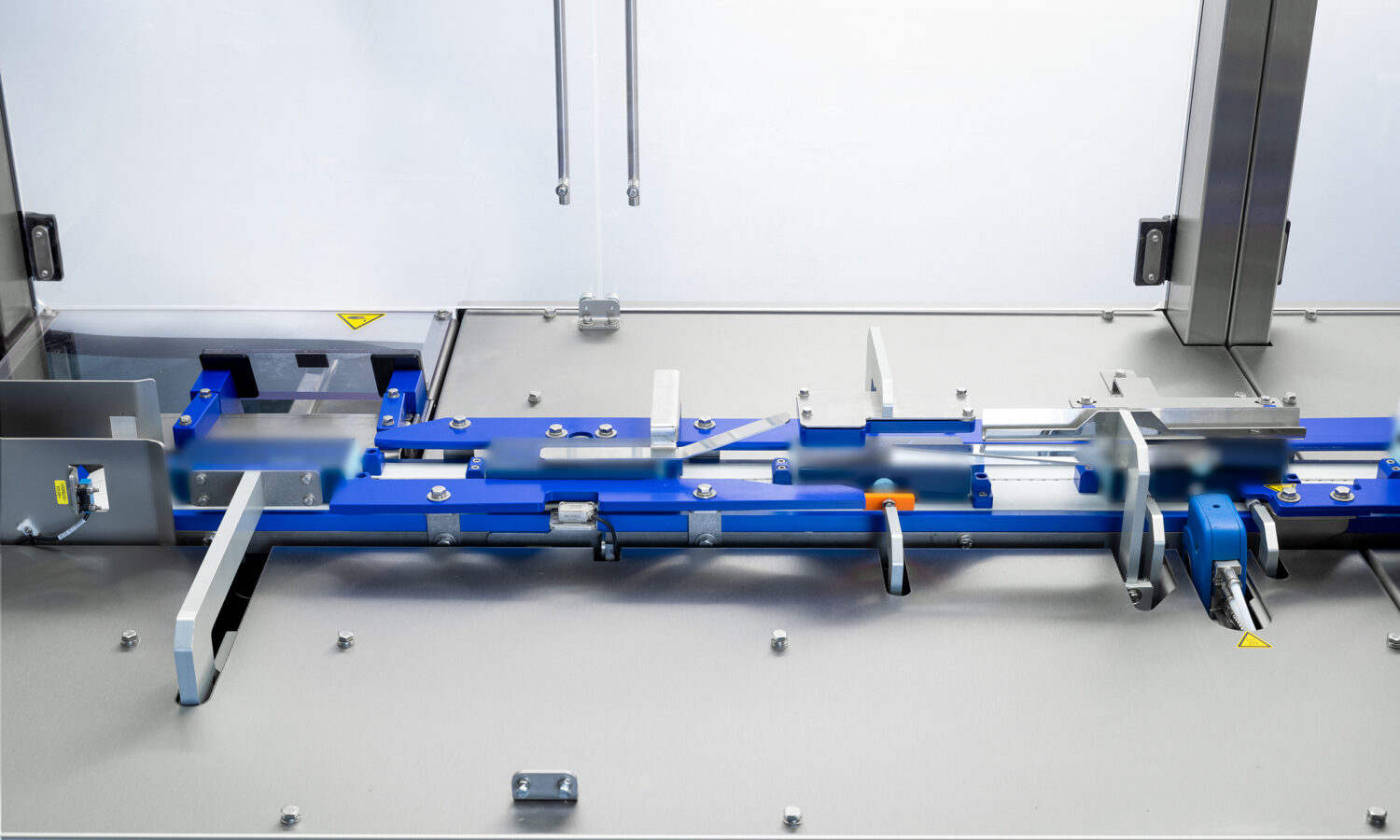

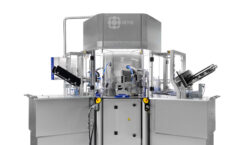

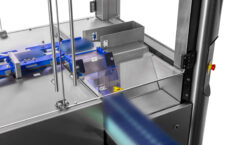

The folding and gluing process initiates in the LAP-C modules of this machine. While the customer opted for two LAP-C Platforms, provisions have been made to add a third LAP-C Platform in the future. Using flat sheets (planos), boxes are folded and glued in the LAP-C Platforms through various steps. At the first station, the plano is folded, glue is applied, and the base is folded. The double side flaps are then folded and glued at the second station, with a drop of hot-melt glue placed on the bottom for the insert. Additionally, variable data and a datamatrix are printed here. The insert is then folded and pressed into the hot-melt glue at the third station. The overlid cover is folded at the fourth station. The fifth station is currently unused, serving as storage for spare parts. The box passes through this station and proceeds to the sixth and final station, where the print from the second station is checked using a Vision system with OCR. Subsequently, the box is transported to the LAP-L Platform via a linear conveyor belt. The hot-melt glue is applied on-the-fly during the movement between stations.

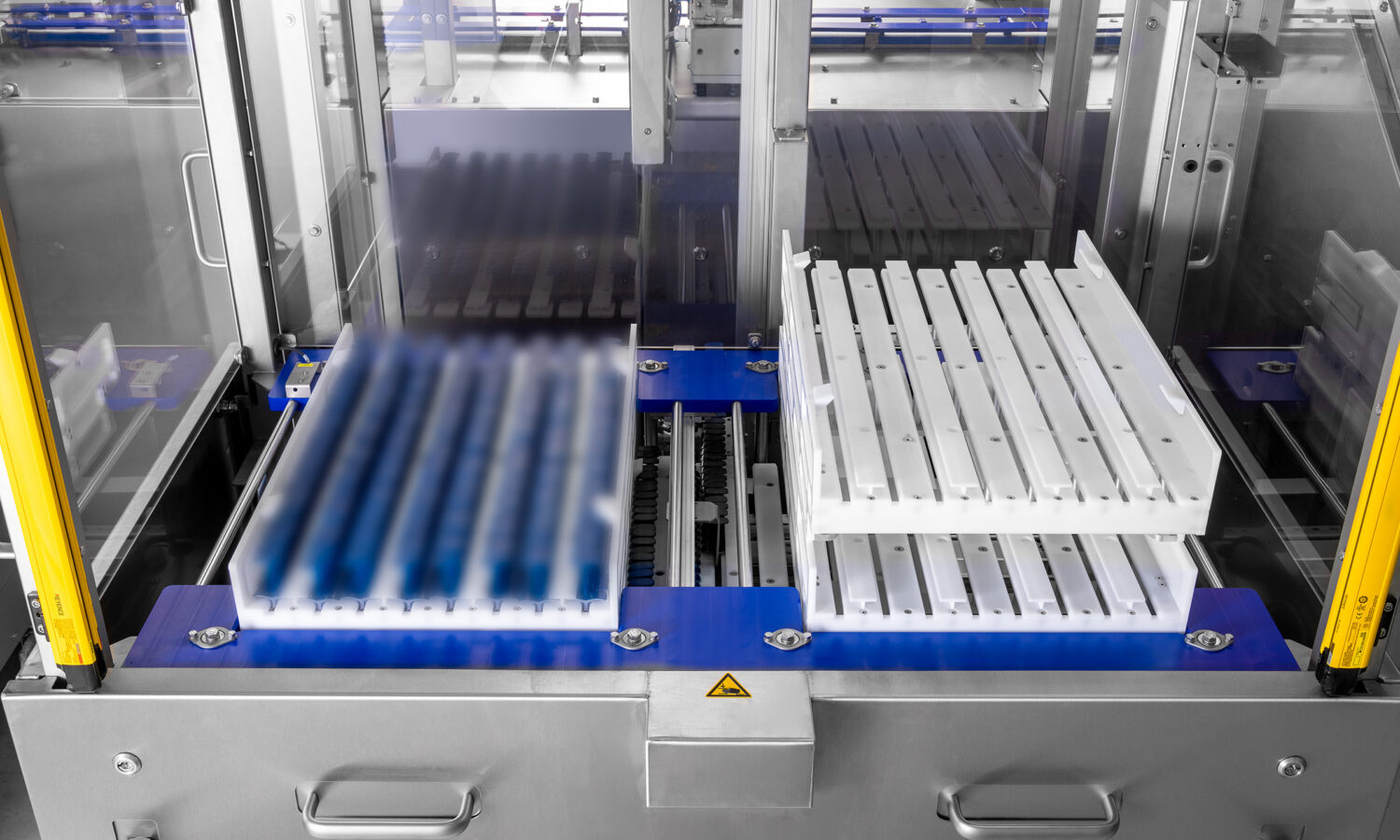

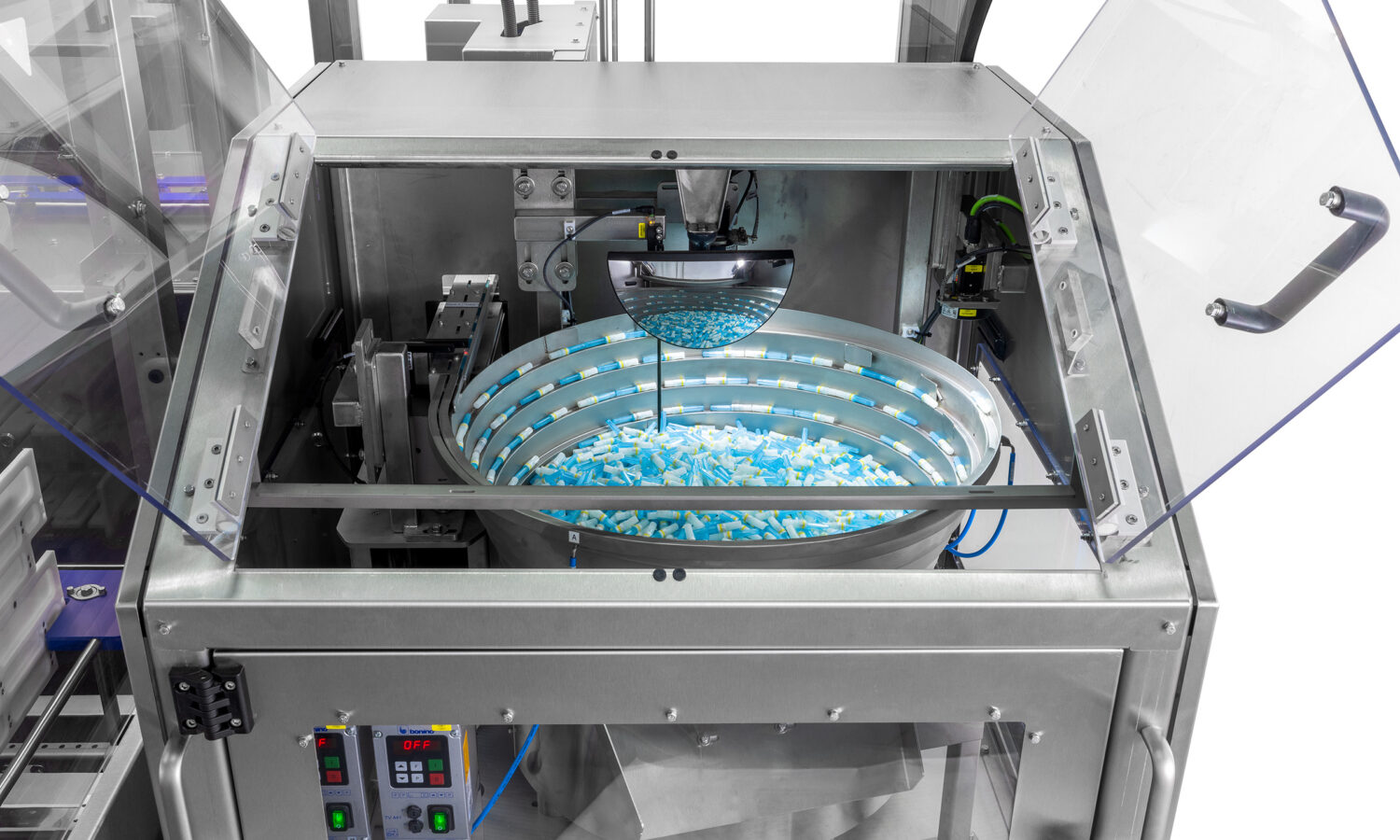

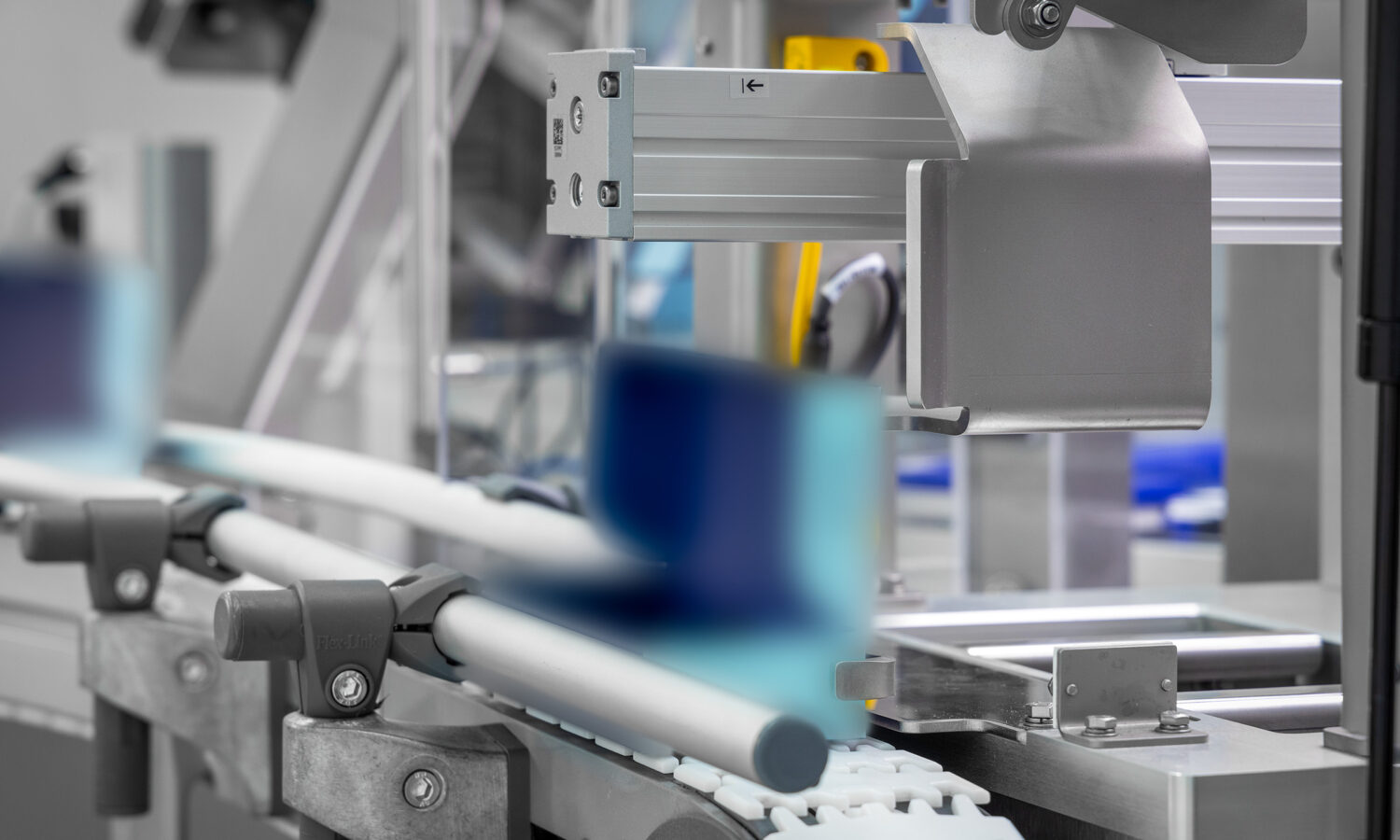

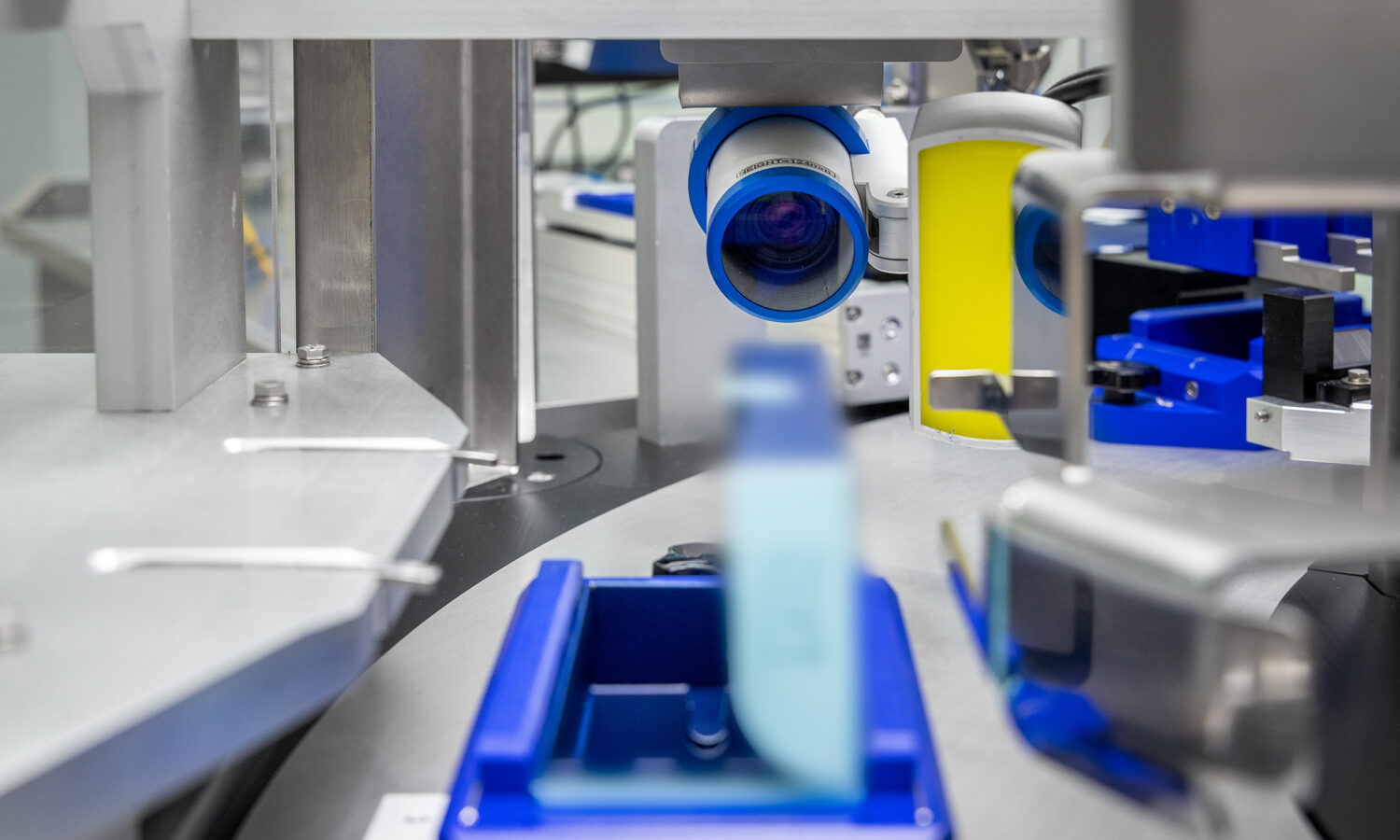

Filling and Sealing

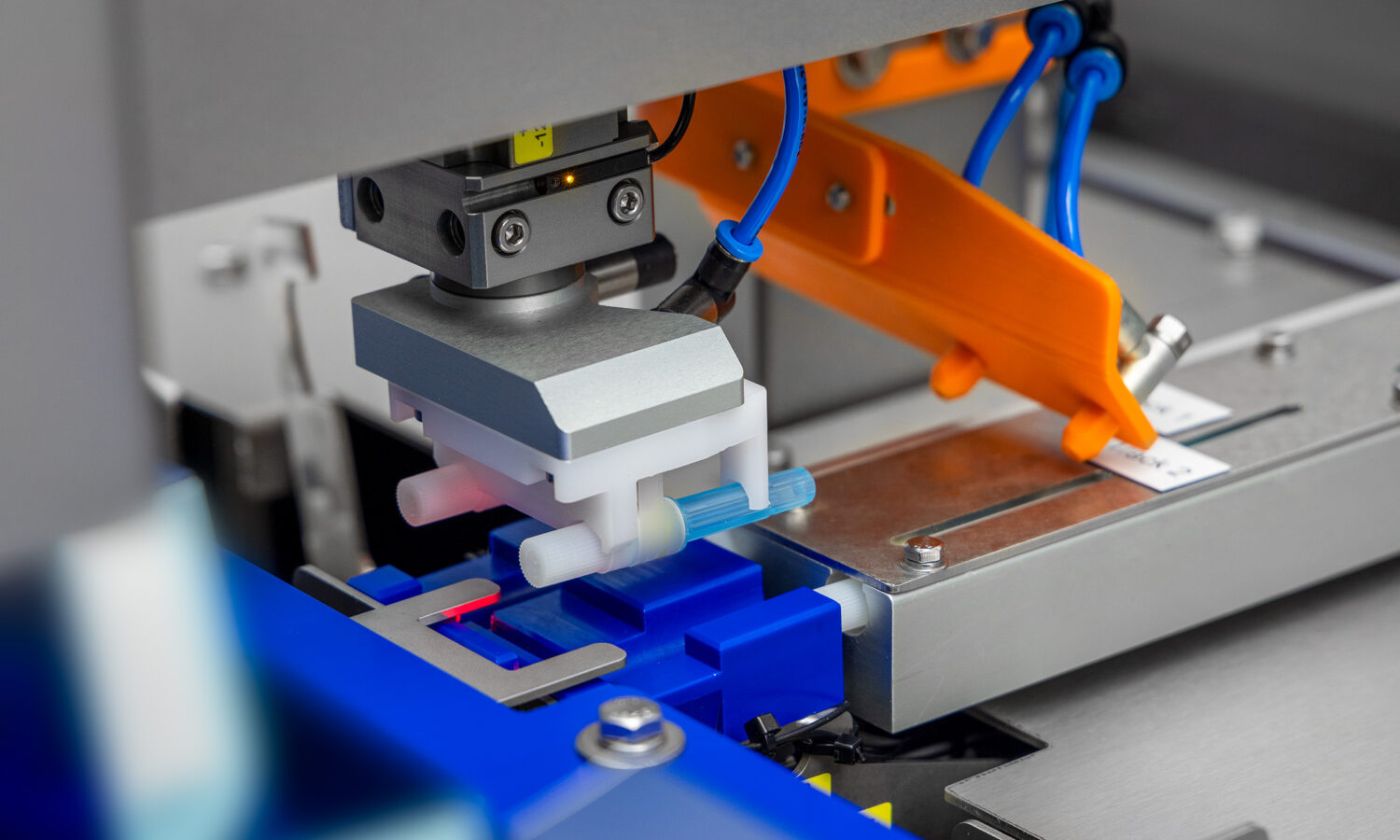

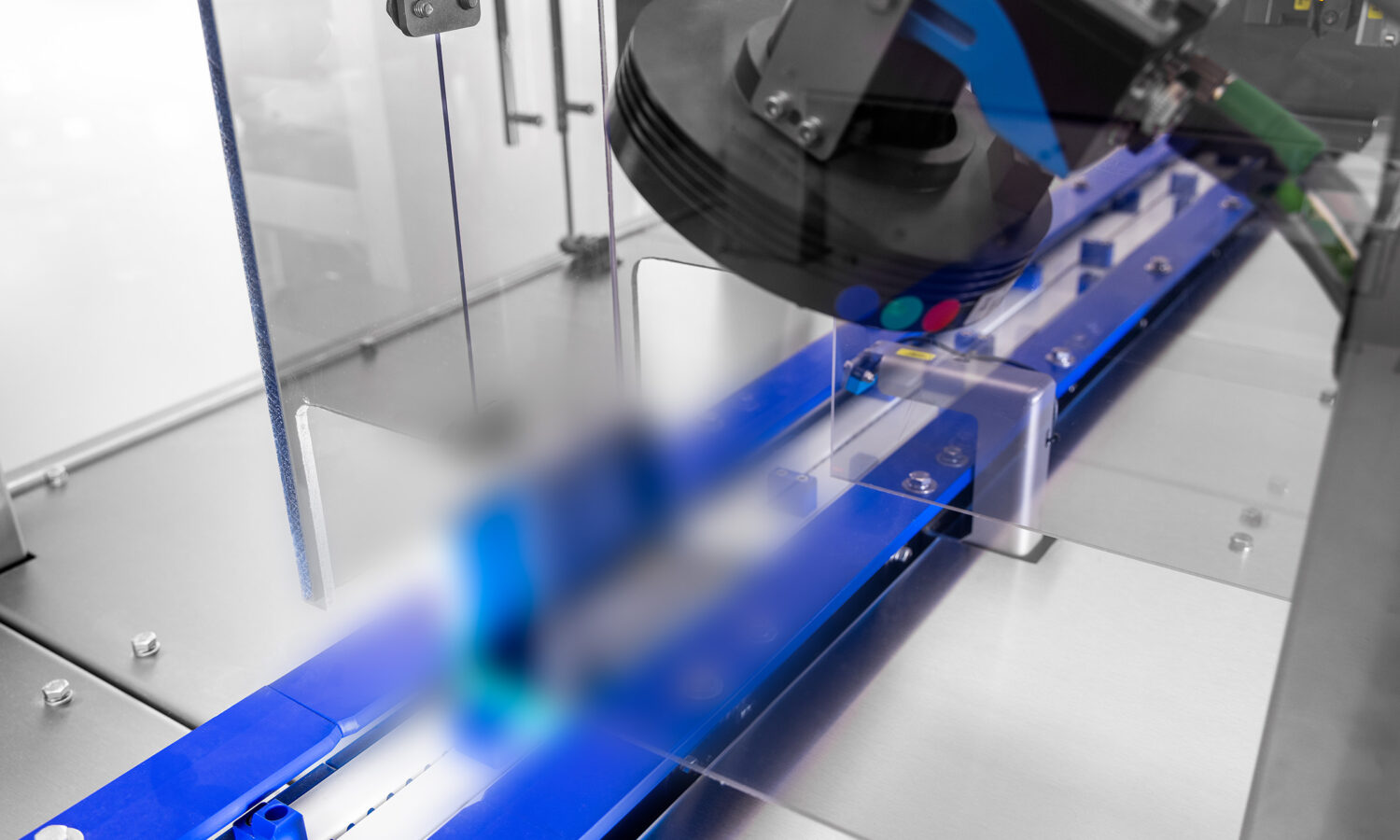

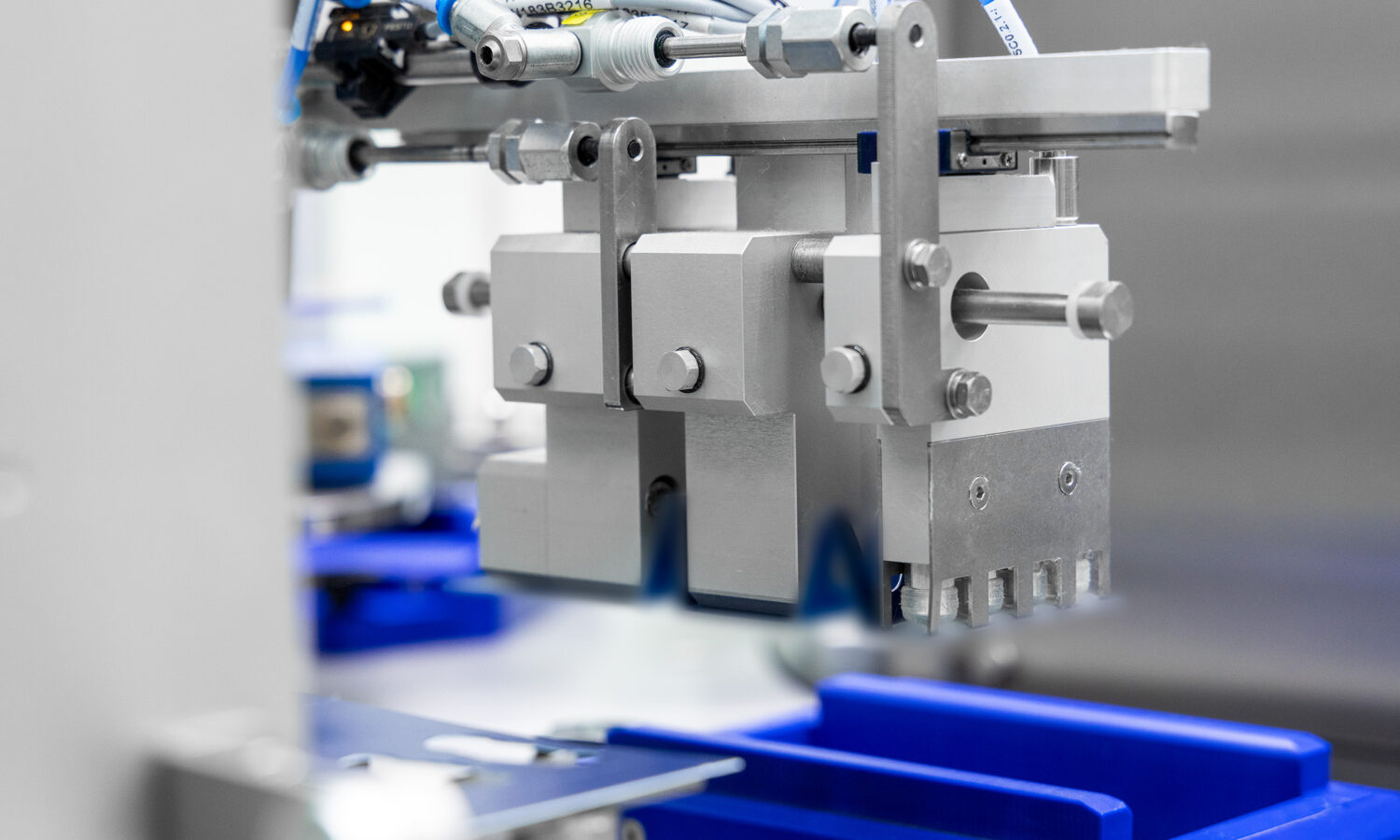

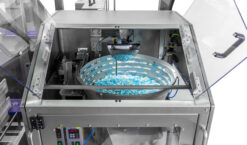

The filling and sealing of the box occur in five steps in the LAP-L Platform of this machine. The LAP-L Platform, in this application, comprises five stations. In the first station, needles are separated and properly oriented using a vibratory bowlfeeder. These are then picked up by a gripper and placed in the box. In the second station, syringes assembled by the Syringe Assembly Machine are taken from the tray and positioned in the box. The presence of components is verified through a Vision check.

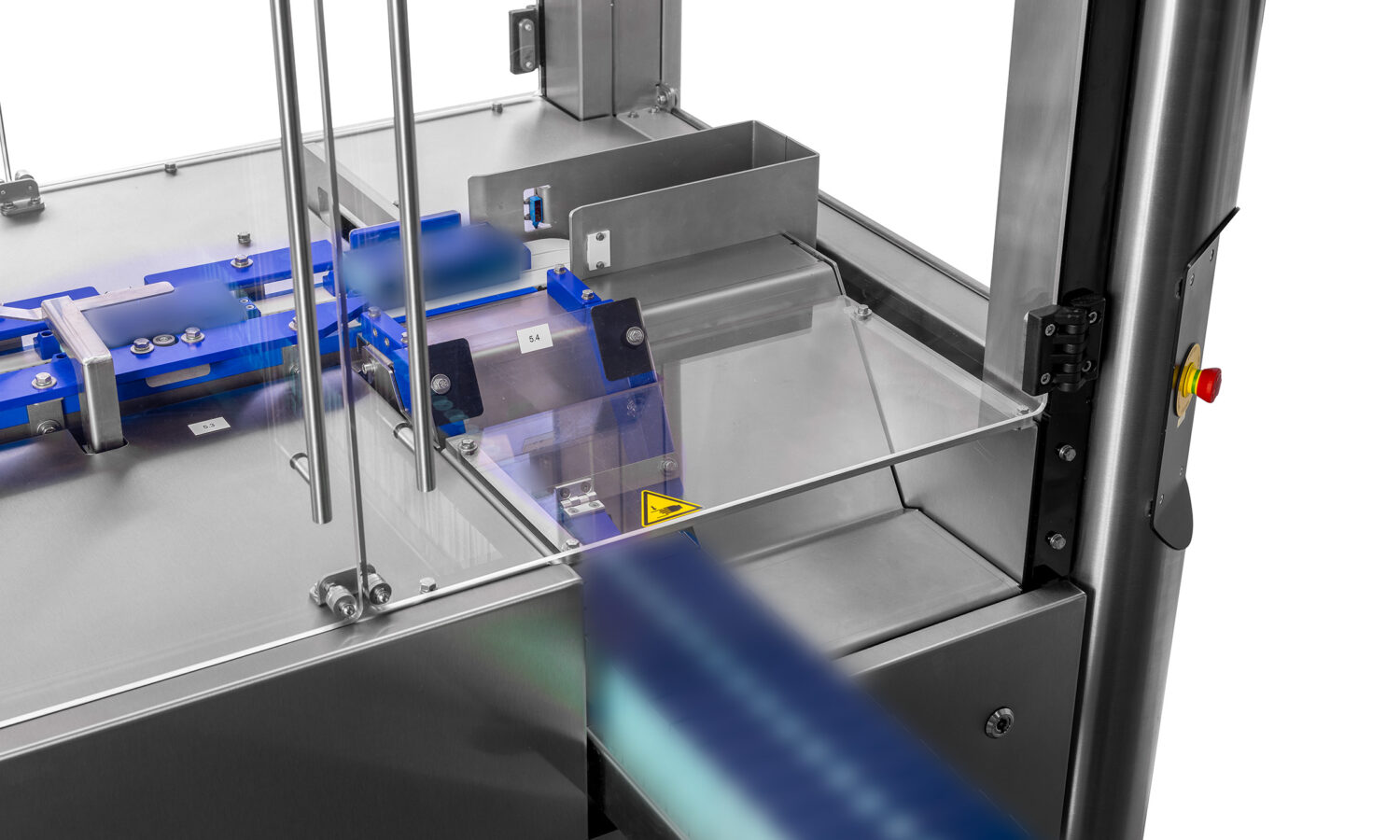

The third station prints a label, cuts it from the roll, and places it in the box to be used as a sticker for the medical record. The fourth station adds the leaflet. An important feature is that the leaflets can be replenished from a docking station during production. When one of the docking stations is nearly empty, operators are alerted through integrated LED panels in the machine’s ceiling. The fifth station in the LAP-L Platform serves as the sealing station: a drop of hot-melt glue is sprayed on the box, and then the box’s lid is folded and pressed. This box closure is monitored by a sensor before being carried out on a packaging table.

Dimensions

LAP-C: 2,5 x 3 x 2,6 (lxwxh)

LAP-L: 6,4 x 2 x 2,6 (lxwxh)

Specifications

- Suitable for various box types and configurations

- Modular construction for future expansion

- Equipped with convenient docking stations

- Medium to high capacity, up to 30 boxes per minute

- User-friendly Siemens control

- Fully automatic with a unified control system for all machines

Get more information

Wondering how the Machine could be useful for your organisation? Request more information using the form below.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)