The Process

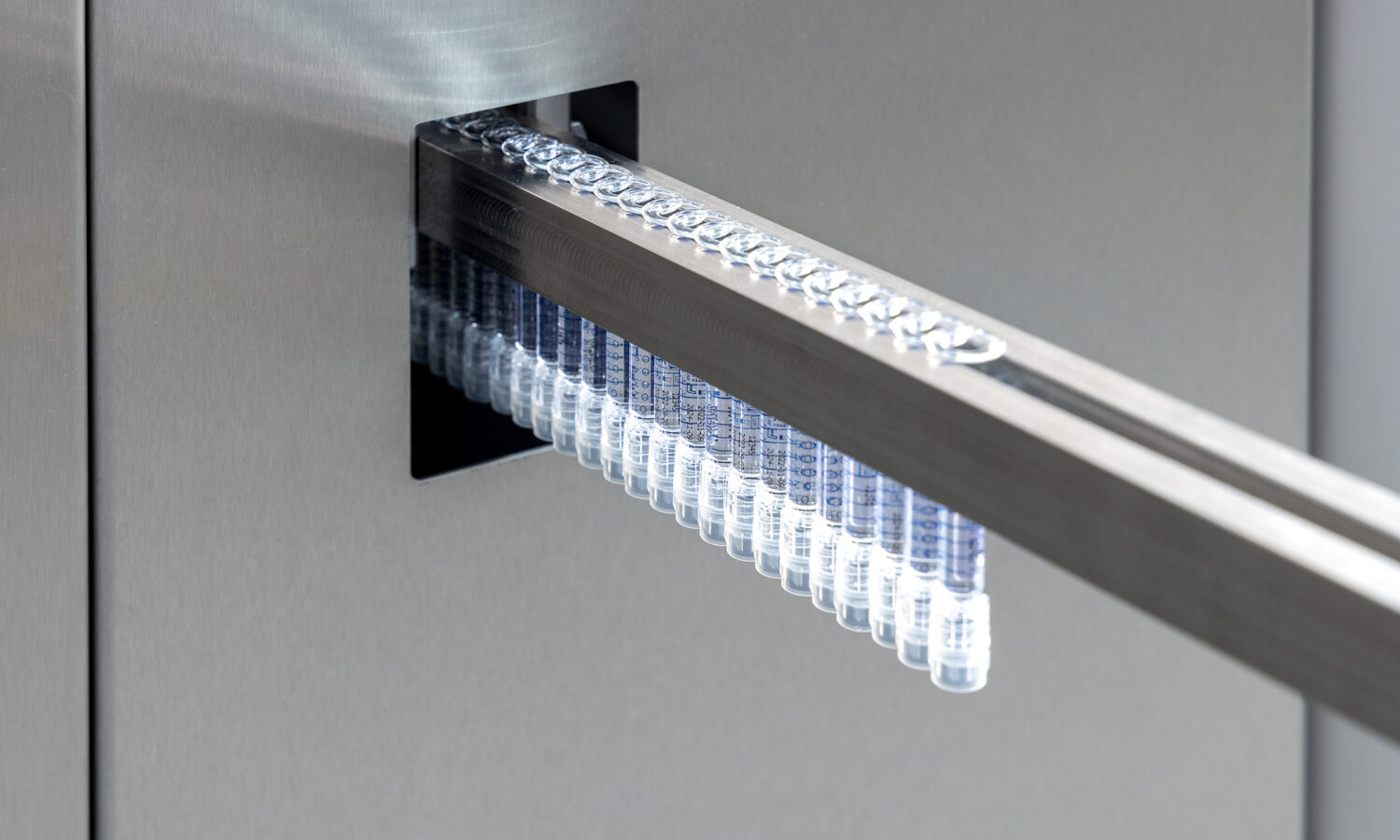

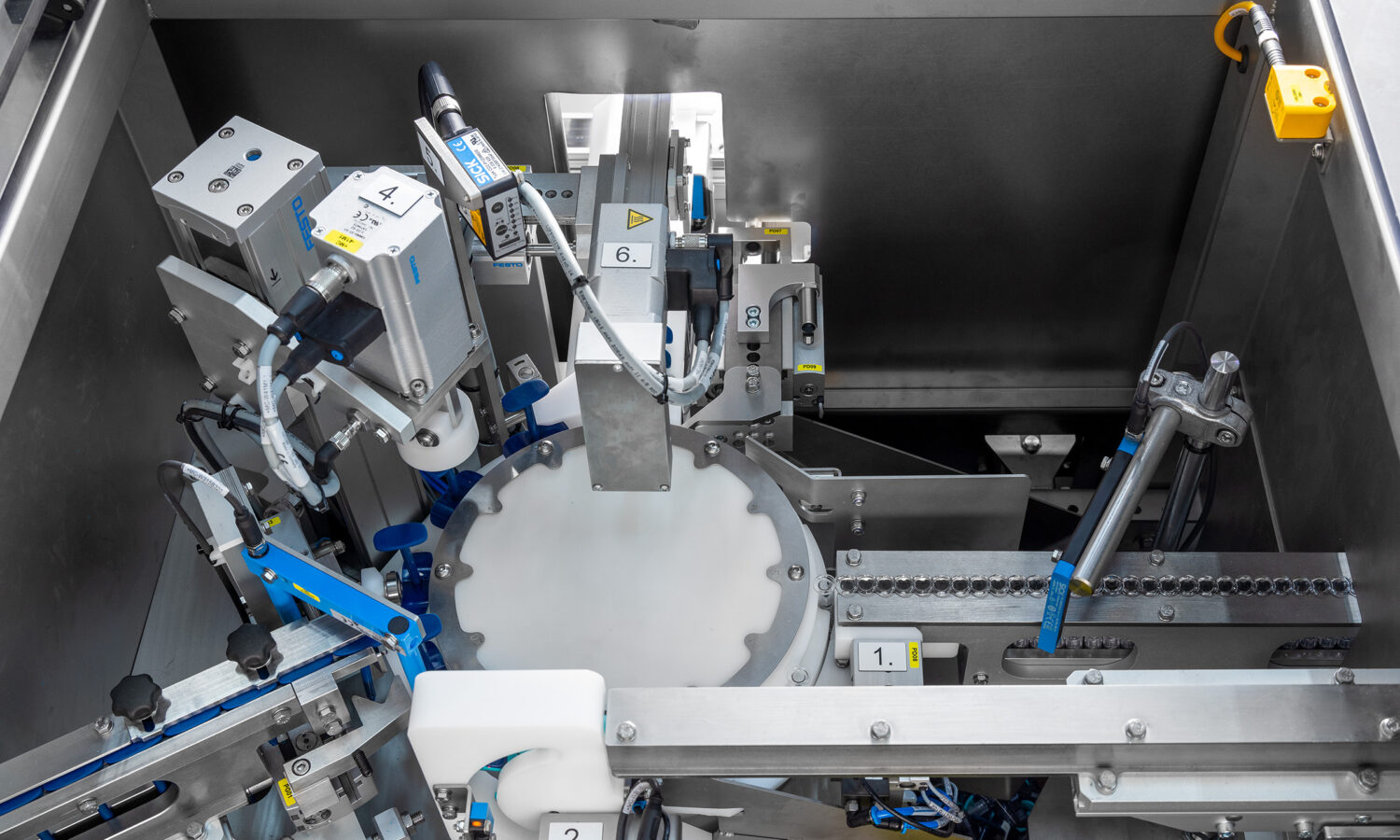

Syringes are transferred from another machine using a linear vibrating filler towards the Syringe assembly machine. Subsequently, after a distance sensor check, they are correctly positioned in the machine. In the second station of the machine, the fingergrip is attached to the syringe. This is done with a preset force to ensure the syringe remains usable and undamaged.

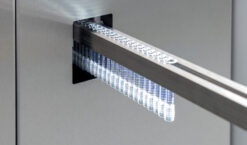

Both the fingergrips and the plunger rods in the third station are bulk-fed. These components are separated and correctly oriented using vibrating fillers, then transported linearly to the clicking station. In the third station, a gripper places the plunger rod in the syringe, which is then correctly twisted into the syringe in the fourth station. Finally, in the fifth station within the machine, the syringe is checked for several aspects using multiple sensors, including the height of the plunger rod and the presence of a fingergrip.

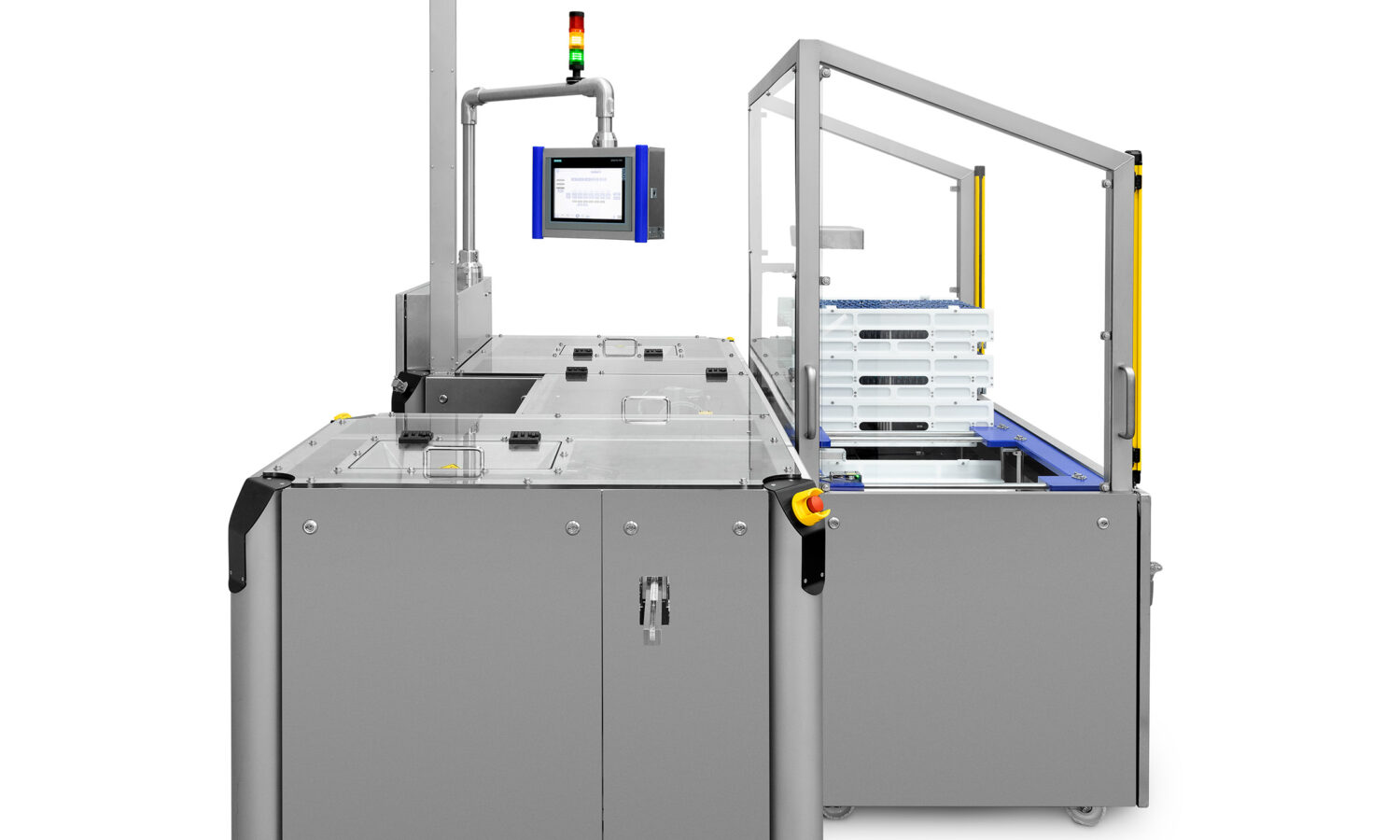

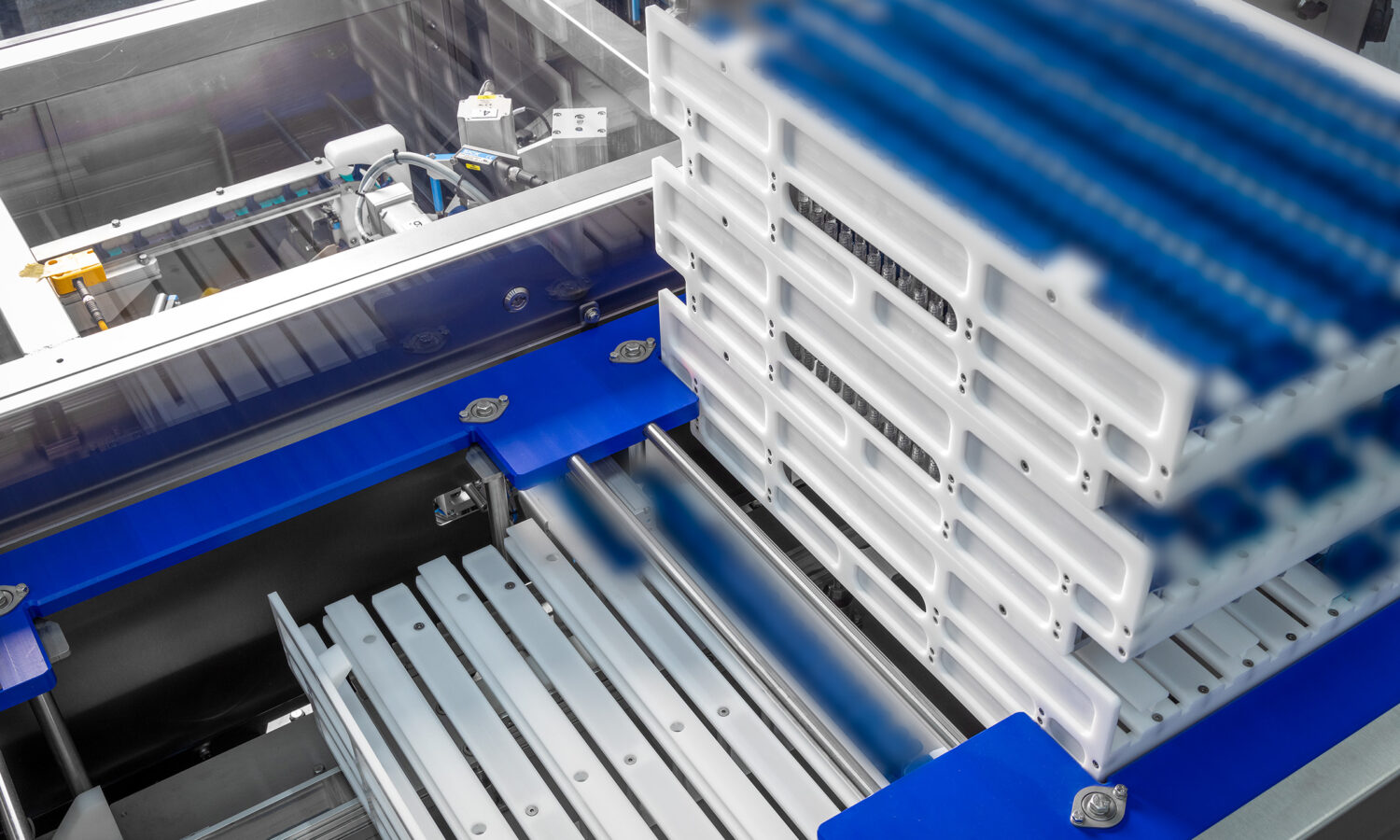

If this check passes, the syringe is automatically placed in a tray, which, when fully filled, can be manually taken to the docking station by the operator. If the assembled end product does not meet the required conditions, it is marked as a reject and automatically directed to the reject station. This ensures a clear separation between correct and deviating end products, preventing any mix-ups.

Specifications

- Suitable for assembling two variants

- Custom tray system

- Compact footprint

- 30 syringes per minute

- Checking various aspects of the syringe using a Vision system

- 240 syringes per tray

- The docking station for assembled products accommodates eight trays

Requesting assets

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields