Guarantee the quality of your packaging

The quality of any given package depends on several factors, including welding temperature, sealing pressure (also called welding pressure), welding impurities, and the composition of relevant materials.

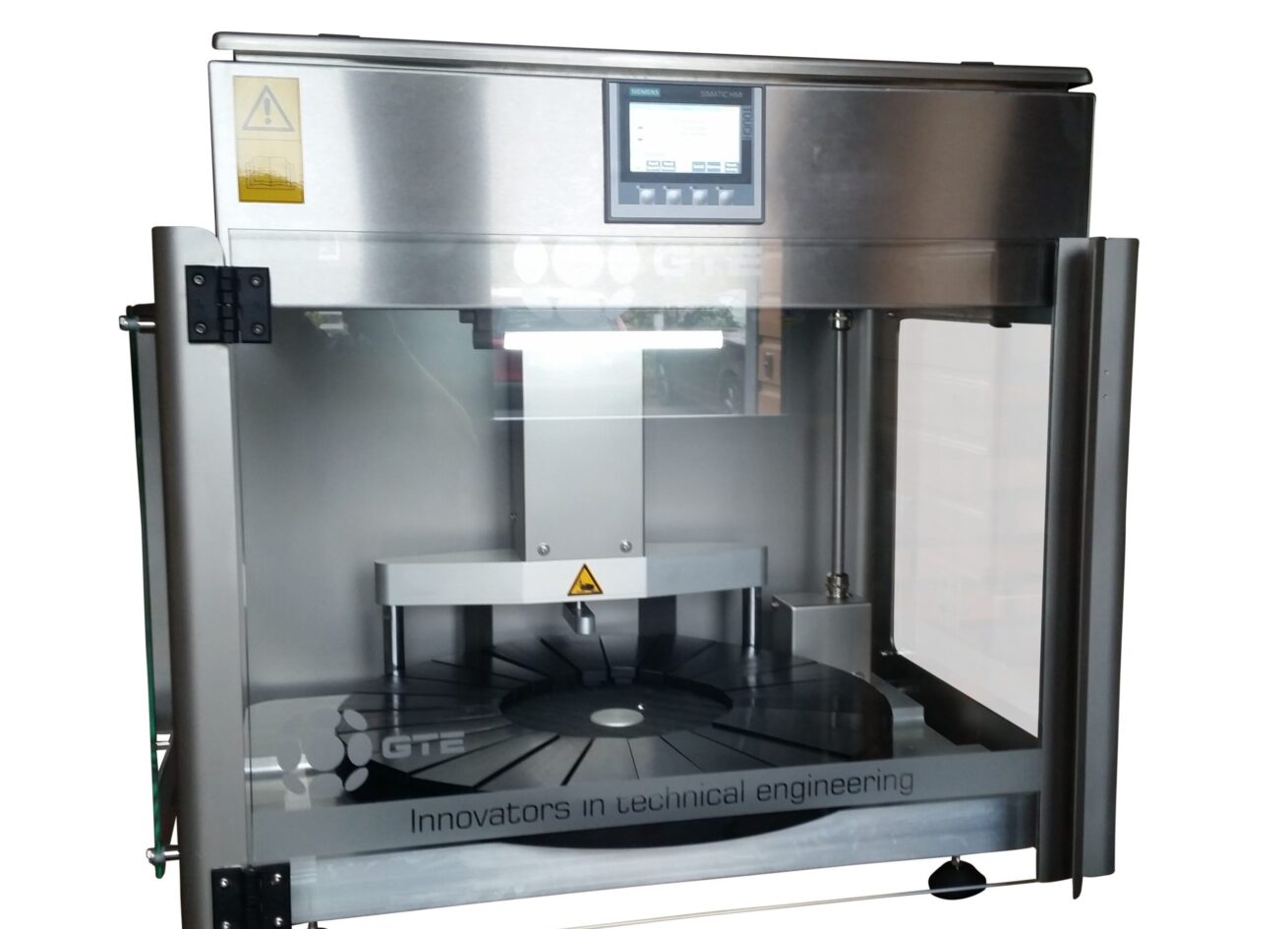

The Bursting strength tester tests the seal and weld quality of a batch of sachets or stick packs in two different ways: destructive and non-destructive. During destructive testing, the Bursting strength tester compresses products and measures the force and displacement of the compression piece necessary to cause the packaging to fail. During non-destructive testing, the product has to withstand a manually entered amount of pressure. Does the packaging pass this test and remain intact? Then it meets the specified requirements.

Specifications of the bursting strength tester

- Efficient

- Destructive and non-destructive testing

- Inserts are easy to clean

- Short change-over time

- Test approximately 20 to 30 products per cycle

- Data is written into a CSV file

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)