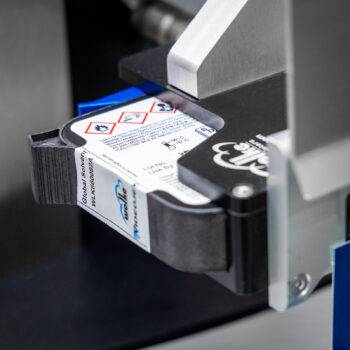

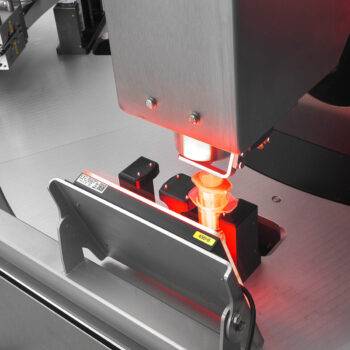

Multiple uses for vision check

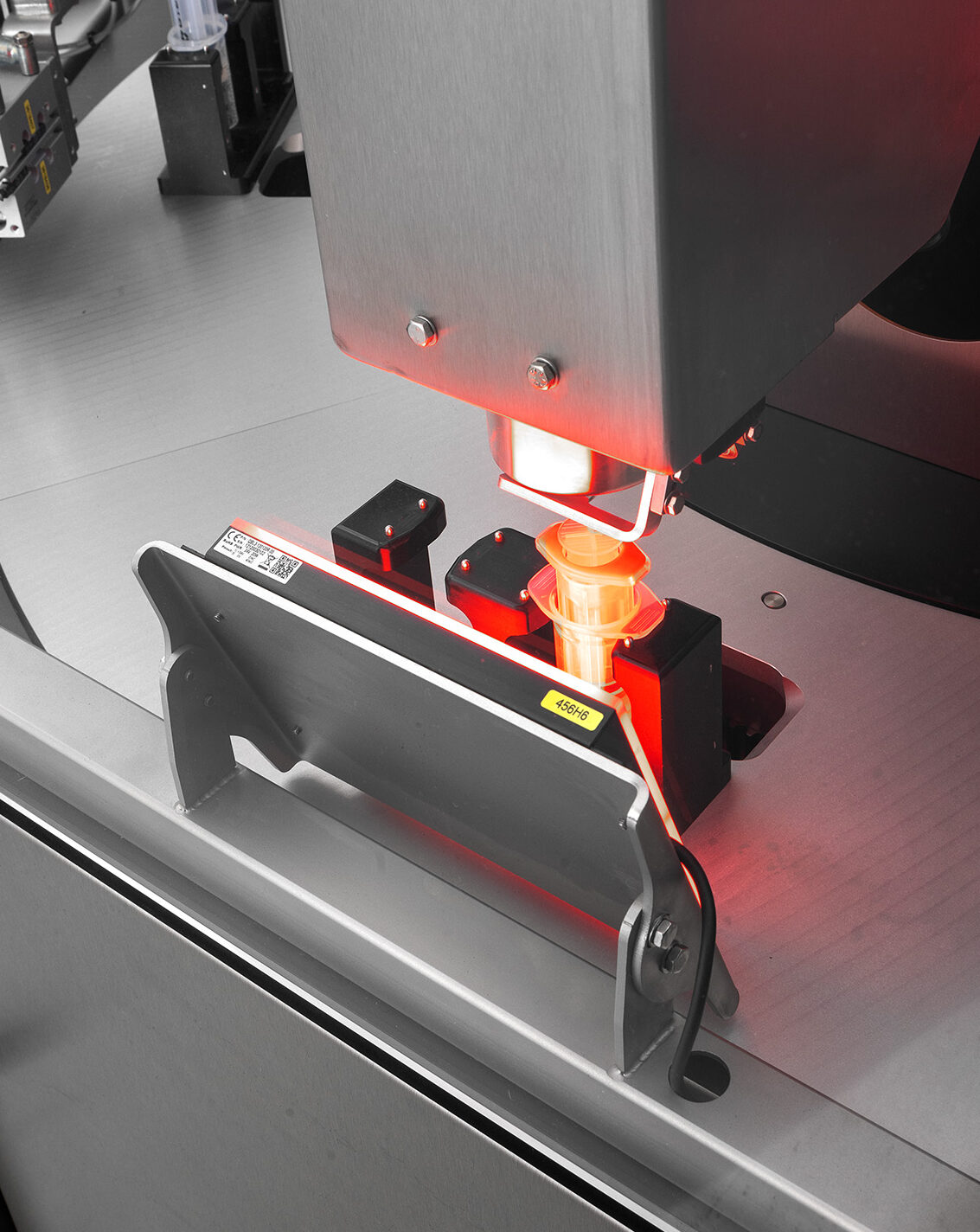

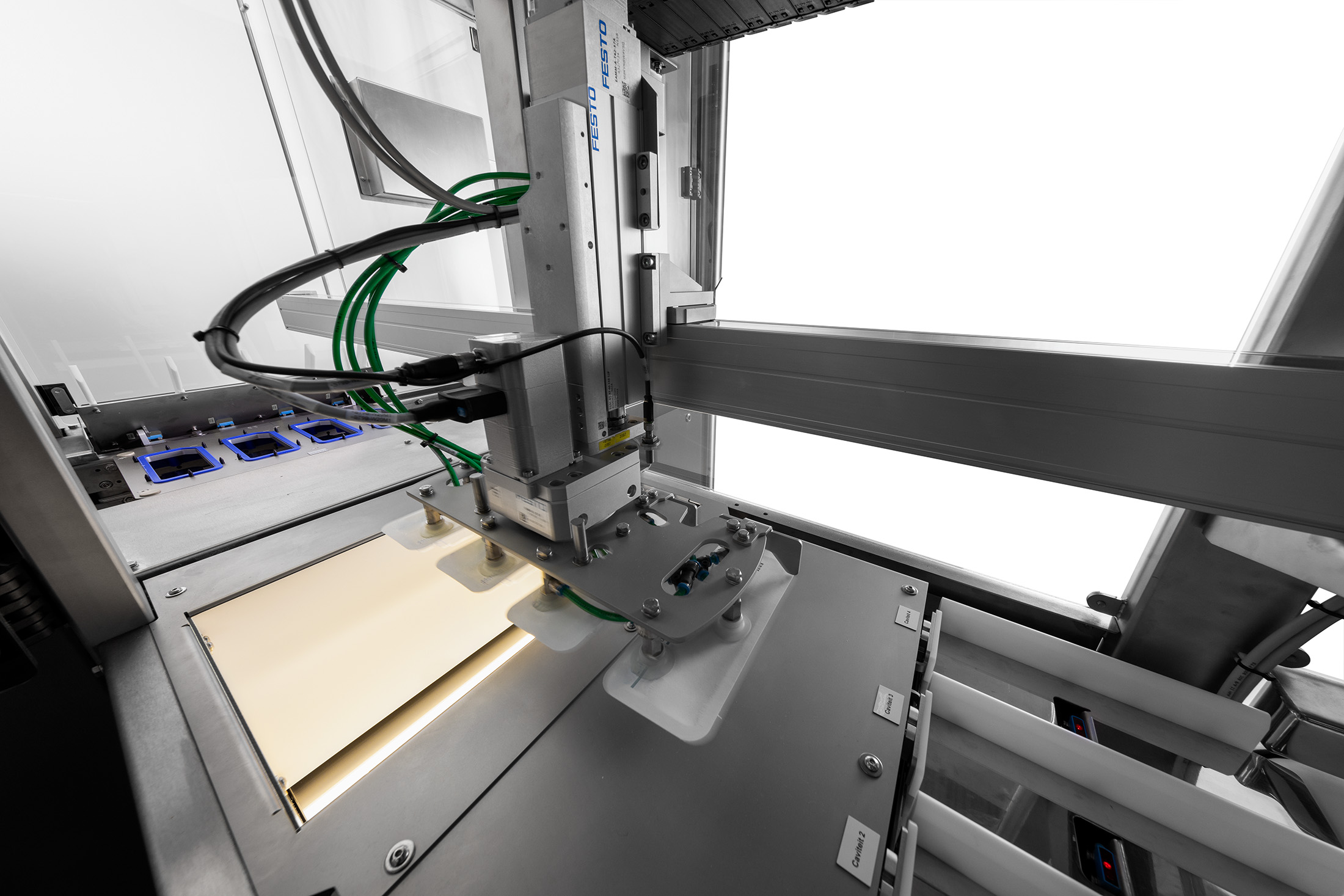

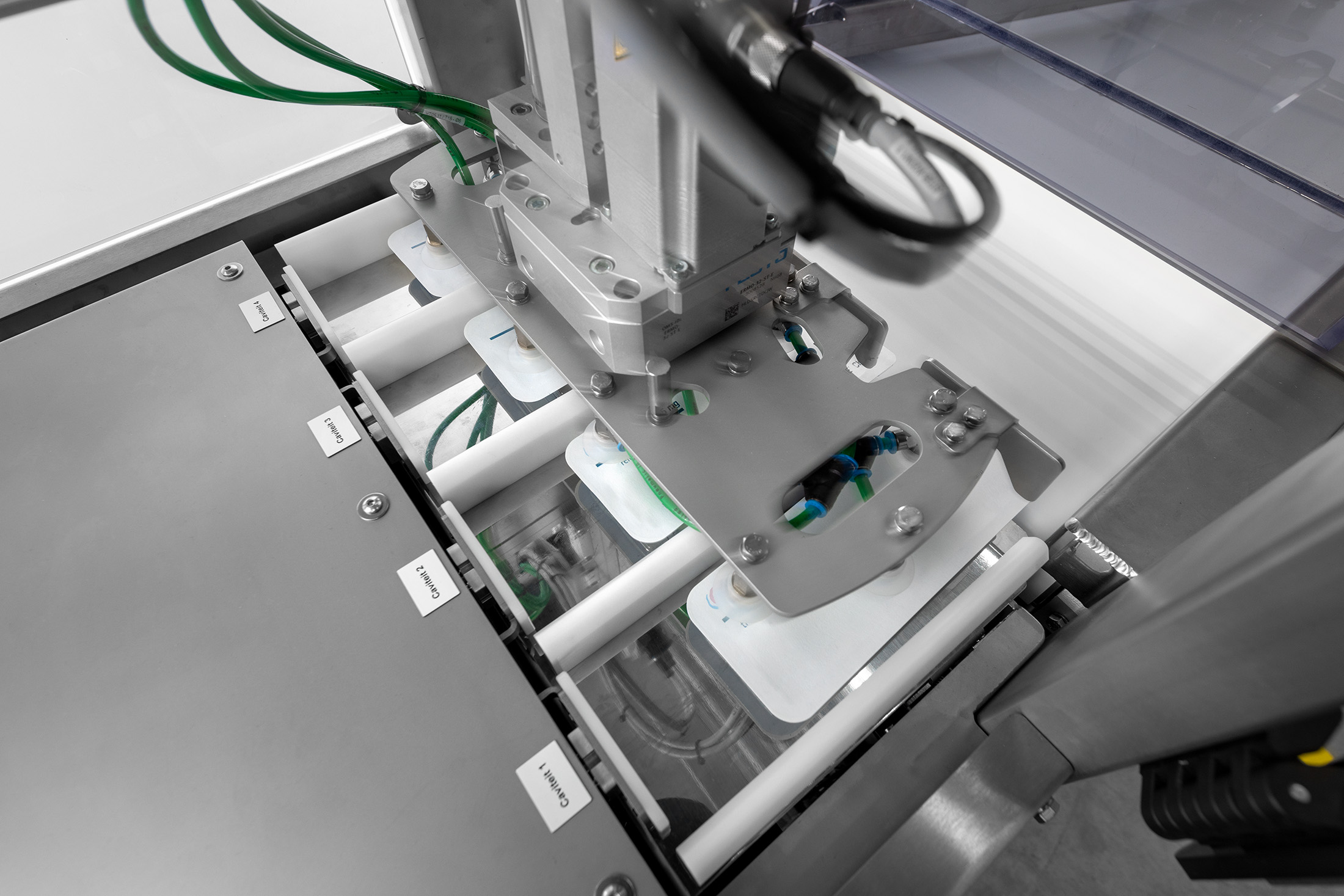

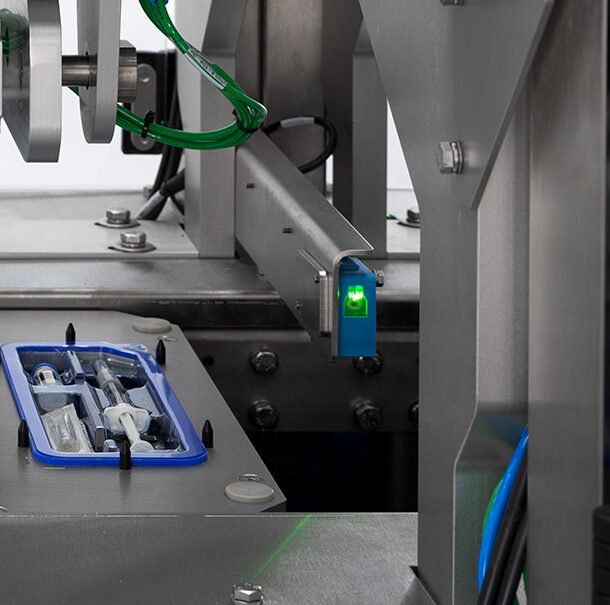

As indicated, you can check all sorts of things with Vision systems. Whether you want to make sure your recently sealed packages are free of contamination and the seal quality is perfect or check a 2d-matrix containing data about your production process or maybe you want to check if products are correctly oriented in the input bin or placed correctly in the. In short, the sky is the limit.

Quality assurance through vision check

A higher level of automation contributes to production line efficiency and higher quality of the final product. The more automated your process is, the smaller the margin of error will be. However, this quality has to be checked and guaranteed. By applying Vision systems, you can be sure that the low error rate that occurs on an automated line is a thing of the past. This is because various solutions can be built in that automatically mark the product as “Reject” if an error is detected. The rejected product is then removed from the production line at a designated point and placed in a separate bin. This allows you, possibly in combination with information from the logging system, to find out what the error is.

Tailored to your needs

At GTE, we understand that validation and consistency are important sticking points for the medical and pharmaceutical industries. If a customer needs to switch to a completely new Vision system, it can pose some challenges to those values. That’s why we also offer the ability to integrate the Vision system you are currently working with into our machines. You’re not limited to our supplier when it comes to quality assurance.

Get more information

Wondering how the Machine could be useful for your organisation? Request more information using the form below.

"*" indicates required fields

Knowledge & Inspiration

Whitepaper: Everything about vision systems in the pharmaceutical and medical industry

Precision and accuracy are extremely important. Whether they are used for correctly labeling products, or verifying the integrity of packaging, vision systems play a crucial role in any production process. What are their strengths and limitations, how do you prepare for their implementation, and what will the future look like in terms of, for example, AI? We are happy to help you get started; download the free whitepaper!

The Importance of IQ, PQ, and OQ in Machine Construction for the Pharmaceutical and Medical Industry

In the pharmaceutical and medical industries, developing machines that meet the highest quality and regulatory standards is essential. Therefore, the steps of IQ (Installation Qualification), PQ (Performance Qualification), and OQ (Operational Qualification) are followed during the construction of these machines. These qualification tests ensure that machines meet the required standards for installation, operation, and performance, and they are a critical part of the validation process.

At GTE Engineering, we use a traceability matrix and provide support with FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) protocols to make the validation process structured and efficient. This approach guarantees that all requirements are documented and that the machines meet the highest standards in the pharmaceutical and medical industries.

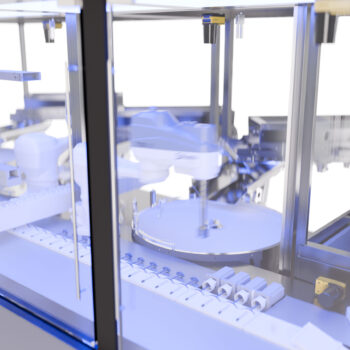

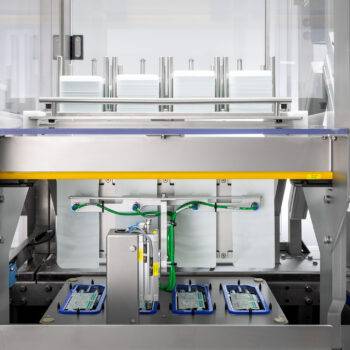

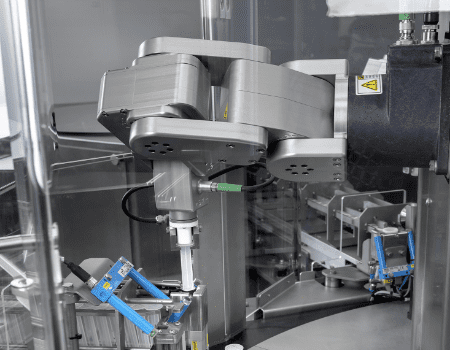

The LAP-C with Mecademic robot

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

What is ‘Smart Customization’?

ETO, CTO and Smart Customization. Terms that are more often used in mechanical engineering. But what do these terms mean? Everyone working in mechanical engineering should know what development these words describe.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)