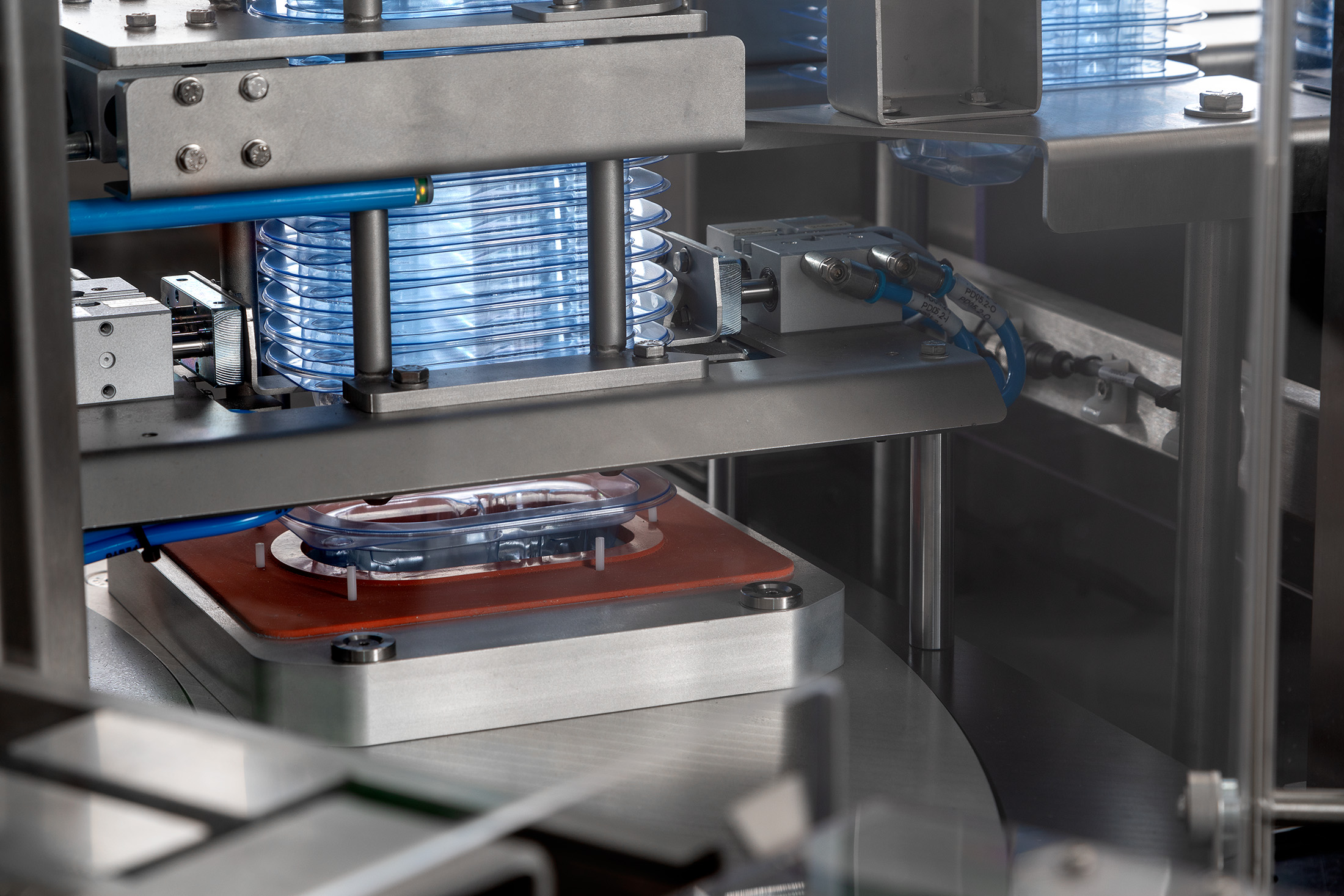

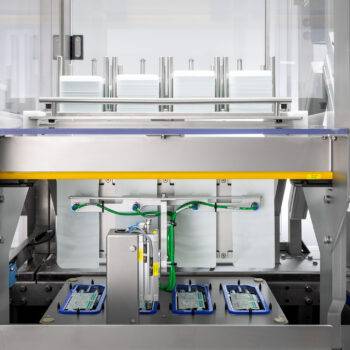

What’s a blister denester?

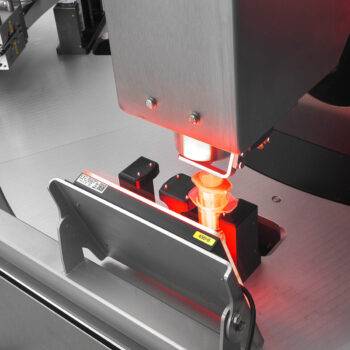

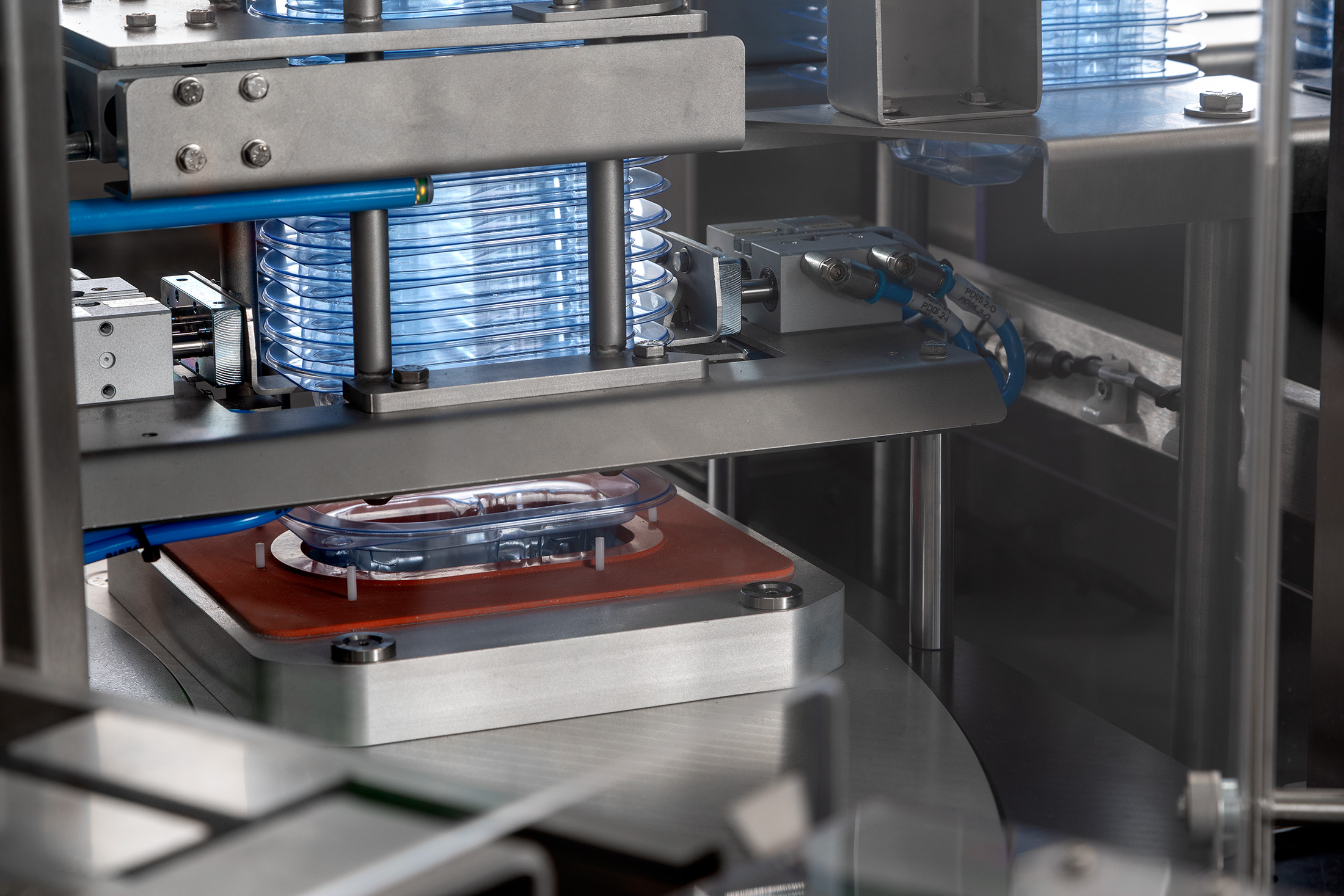

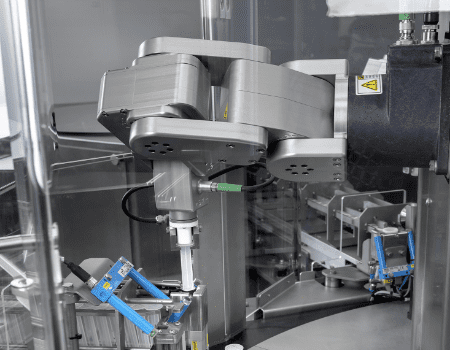

A Blister Denester is a Robot or Cobot which picks blisters one by one from a stack, a box or a conveyor belt and places them in a machine. It uses a Vision system to check that blisters are correctly oriented, there are no blisters sticking together, and nothing is damaged.

Implementing a blister denester

The blister denester is often implemented in our GTE platforms to increase the automation of a process. Here, for example, the Blister Denester is located right after an assembly station to place the assembled products in a blister and then seal them. This is just one of the ways a Blister Denester can be used. Check down below for more ways to use Blister Denester within your organisation.

Get more information

Wondering how the Machine could be useful for your organisation? Request more information using the form below.

"*" indicates required fields

Knowledge & Inspiration

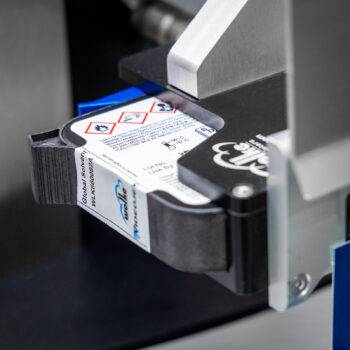

Whitepaper: Everything about vision systems in the pharmaceutical and medical industry

Precision and accuracy are extremely important. Whether they are used for correctly labeling products, or verifying the integrity of packaging, vision systems play a crucial role in any production process. What are their strengths and limitations, how do you prepare for their implementation, and what will the future look like in terms of, for example, AI? We are happy to help you get started; download the free whitepaper!

The Importance of IQ, PQ, and OQ in Machine Construction for the Pharmaceutical and Medical Industry

In the pharmaceutical and medical industries, developing machines that meet the highest quality and regulatory standards is essential. Therefore, the steps of IQ (Installation Qualification), PQ (Performance Qualification), and OQ (Operational Qualification) are followed during the construction of these machines. These qualification tests ensure that machines meet the required standards for installation, operation, and performance, and they are a critical part of the validation process.

At GTE Engineering, we use a traceability matrix and provide support with FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) protocols to make the validation process structured and efficient. This approach guarantees that all requirements are documented and that the machines meet the highest standards in the pharmaceutical and medical industries.

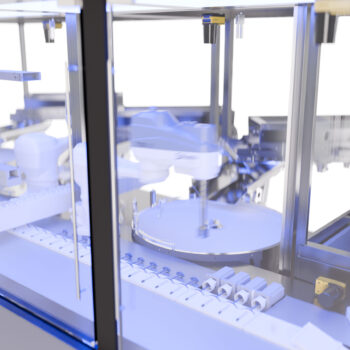

The LAP-C with Mecademic robot

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

What is ‘Smart Customization’?

ETO, CTO and Smart Customization. Terms that are more often used in mechanical engineering. But what do these terms mean? Everyone working in mechanical engineering should know what development these words describe.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields