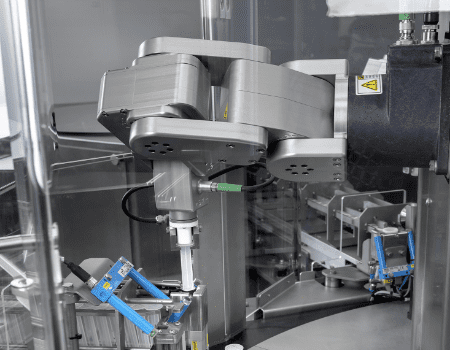

Integrating a robot

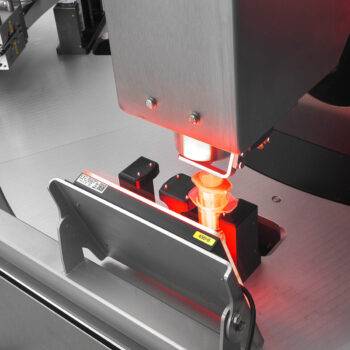

Integrating a Robot is interesting for processes with little or no human operators, with a high degree of automation. As a result, a robot can also be integrated with fewer safety requirements than, say, a Cobot.

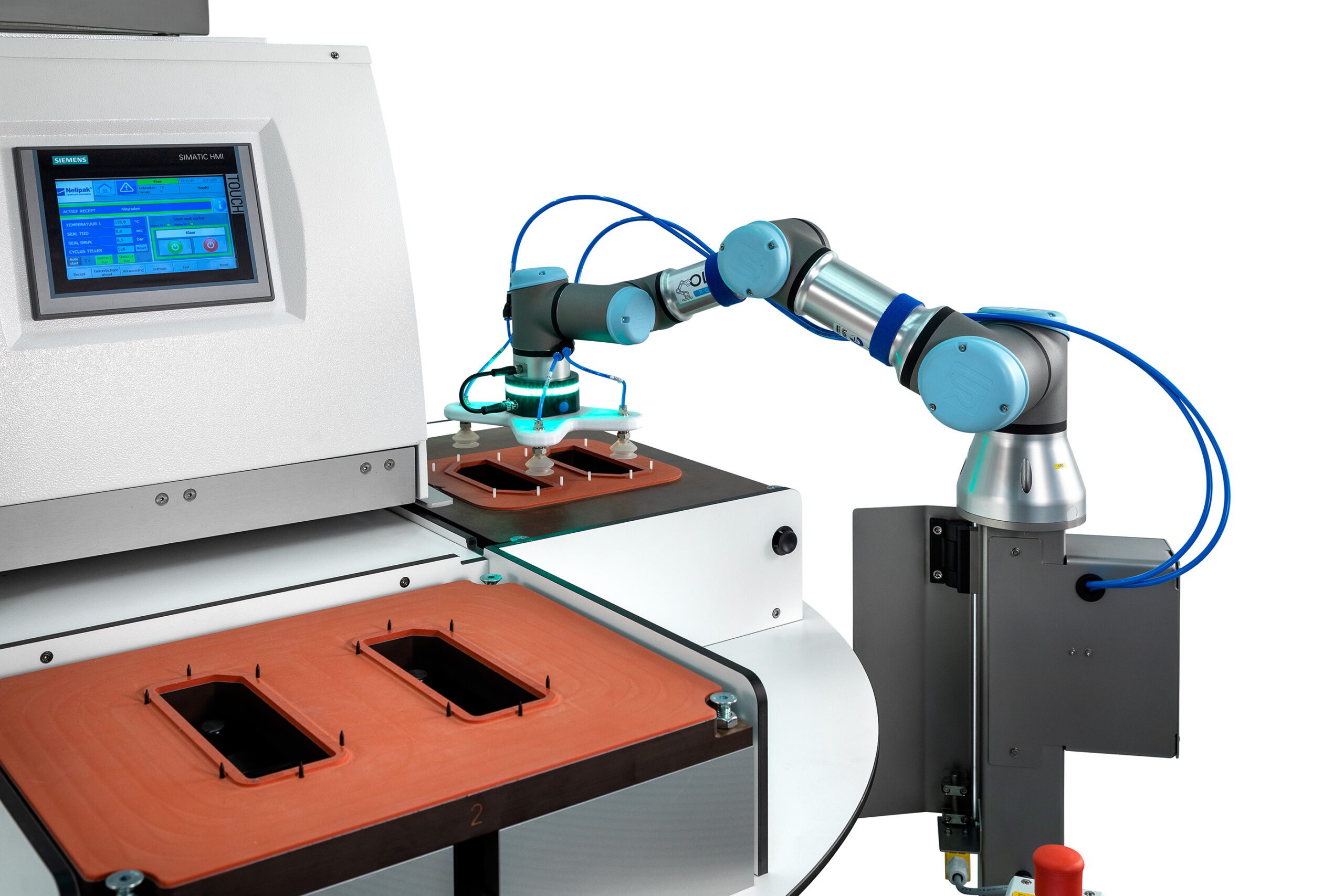

Cobot integration

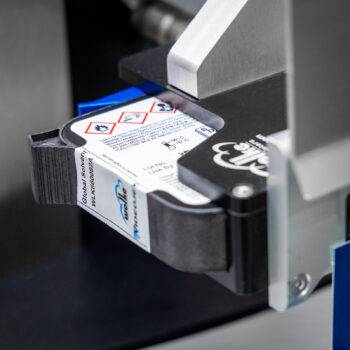

Human operators are central to a Cobot integration: they’re seen as extensions of humans are relatively safe without a lot of additional protocols. As an example, an operator can manually place components or packaging into a machine with a Cobot. A Cobot moves slower than a Robot, and it automatically stops when it detects resistance. That’s why Robots require more safety systems, like light curtains, where the machine stops if small light beams are disrupted, or motion sensors. These ensures the safety and reliability of the machine.

High customisability

Our Robot and Cobot integrations are also well suited for high-mix, low-volume applications. Thanks to our own interchangeable grippers, you can assemble and package different products with the same machine.

The short change-over time means you can get back to production in no time. Greater efficiency and higher ROI are our most important keywords.

All-in-one solutions with robot en cobot integration

Because of GTE Engineering’s years of experience in Robot and Cobot integration, we know how to provide you with the best way to improve a production process. Because GTE develops interchangeable grippers and the programming of the Robots and Cobots in-house, we can quickly adapt everything to your needs. We will also provide our own training to the operators and mechanics who will work with the machine most often.

Get more information

Wondering how the Machine could be useful for your organisation? Request more information using the form below.

"*" indicates required fields

Knowledge & Inspiration

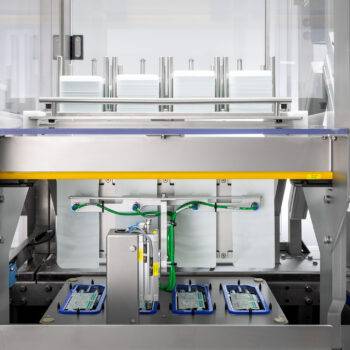

The LAP-C with Mecademic robot

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

What is ‘Smart Customization’?

ETO, CTO and Smart Customization. Terms that are more often used in mechanical engineering. But what do these terms mean? Everyone working in mechanical engineering should know what development these words describe.

Considerations when selecting reputable machine developers

What factors should you consider when selecting a machine builder? Do they meet the stringent quality standards of the medical industry? While there are numerous legal regulations in place to ensure machine and product quality, it’s crucial that machine designers and builders are cognizant of these requirements. Additionally, take into account three key factors that can impact both the machine and your product’s quality: the human factor, the product design, and the proficiency of the machine builder.

Accepting downtime is a mortal sin!

Everyone knows that companies are all about production, or ‘adding value’. Value is everything the customer needs and pays for. All other activities support this. That’s why it’s so strange that unplanned downtime is so quickly accepted and seen as ‘normal’. Many companies are not aware of how often the production line comes to a standstill. People quickly get used to it and accept downtime on a production or assembly line. However, a production line coming to a standstill is disastrous for the organization. If no value is added, the entire organization comes to a standstill.

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)