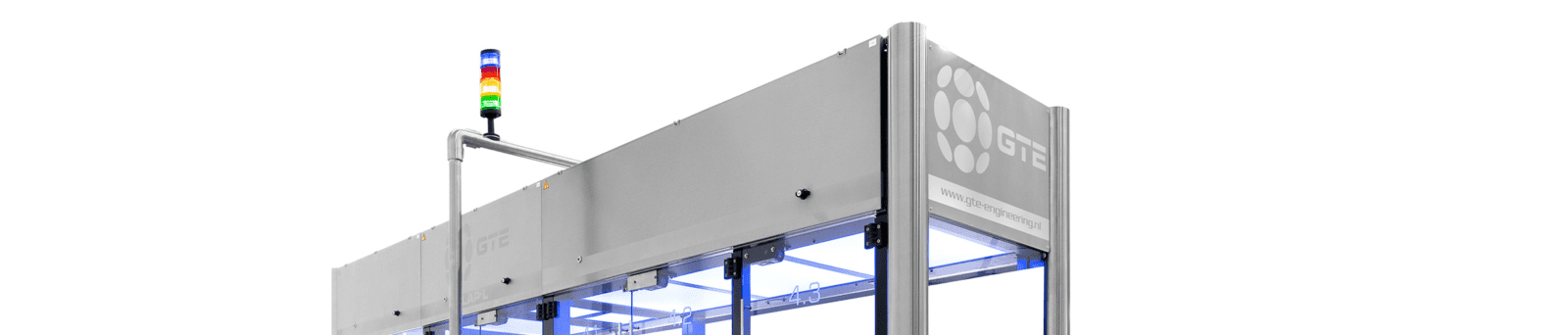

The benefits of automation

Before the customer started using our machine, they were rolling and packaging of by hand, taking up valuable time and labour. Our Bandage Winding Machine offers a (partially) automated solution that makes the process more efficient and profitable for our customers. This machine is capable of rolling up to five bandages at a time and then packing them in a box with ten other sets, fully or partially autonomously. This means that a larger number of bandages can be packed in a shorter time, significantly increasing productivity.

Versatile and flexible

Another advantage of the Bandage Winding Machine is the ability to accommodate different sizes of bandages. Whether they’re small, medium or large in size, our machine can process them all. This means that only one machine is needed to process multiple products, which increases Return on Investment (ROI) and is cost-effective for our customers.

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

Ergonomic design for healthy working conditions

When designing the Bandage Winding Machine, we didn’t just consider efficiency and productivity, but also the health and well-being of operators. Our machine features a height-adjustable base, allowing it to be adapted to the individual operator. This creates an ergonomic working position, reducing the risk of physical health complaints. We value the well-being of the people working with our machines and strive to provide a safe and comfortable working environment.

Why choose GTE Engineering’s Bandage Winding Machine?

With this machine, we’re taking the next step in the automation of bandage rolling and packaging in the medical and pharmaceutical industries. This innovative machine offers numerous advantages, including saving time, improving ergonomics and increasing profitability.

By simultaneously rolling up to five bandages and packaging them with ten pieces, the machine increases productivity and makes this labour-intensive process much more efficient. Additionally, the Bandage Winding Machine can accommodate bandages of different sizes, resulting in a higher ROI for our customers.

The machine isn’t just know for its automation-related benefits, but also its ergonomic design. The height-adjustable base ensures a comfortable and ergonomic working position, reducing the risk of physical health complaints among operators. We aim to create a safe and healthy working environment for the people working with our machines, and the Bandage Winding Machine is an important step in this

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)