The Process

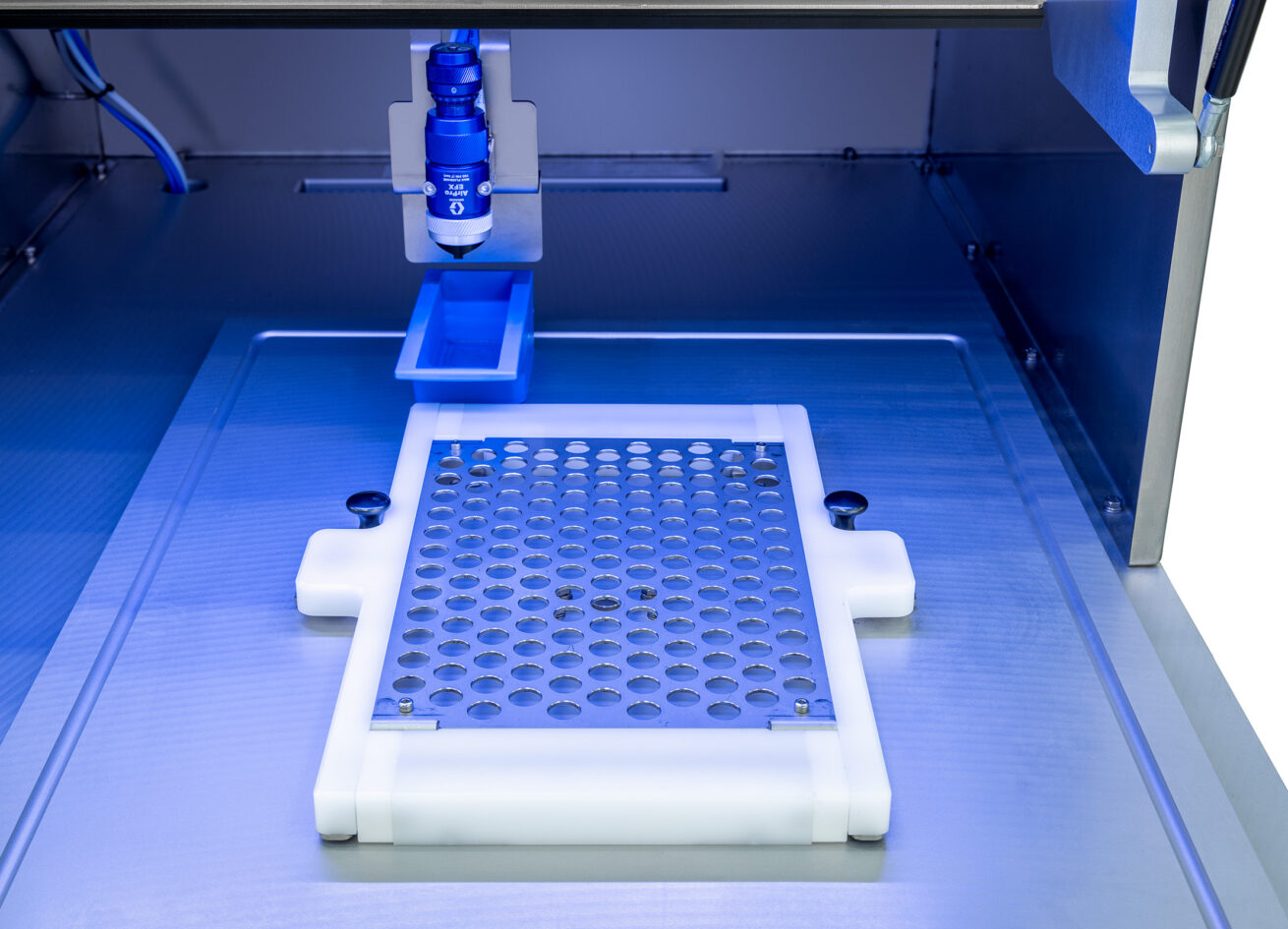

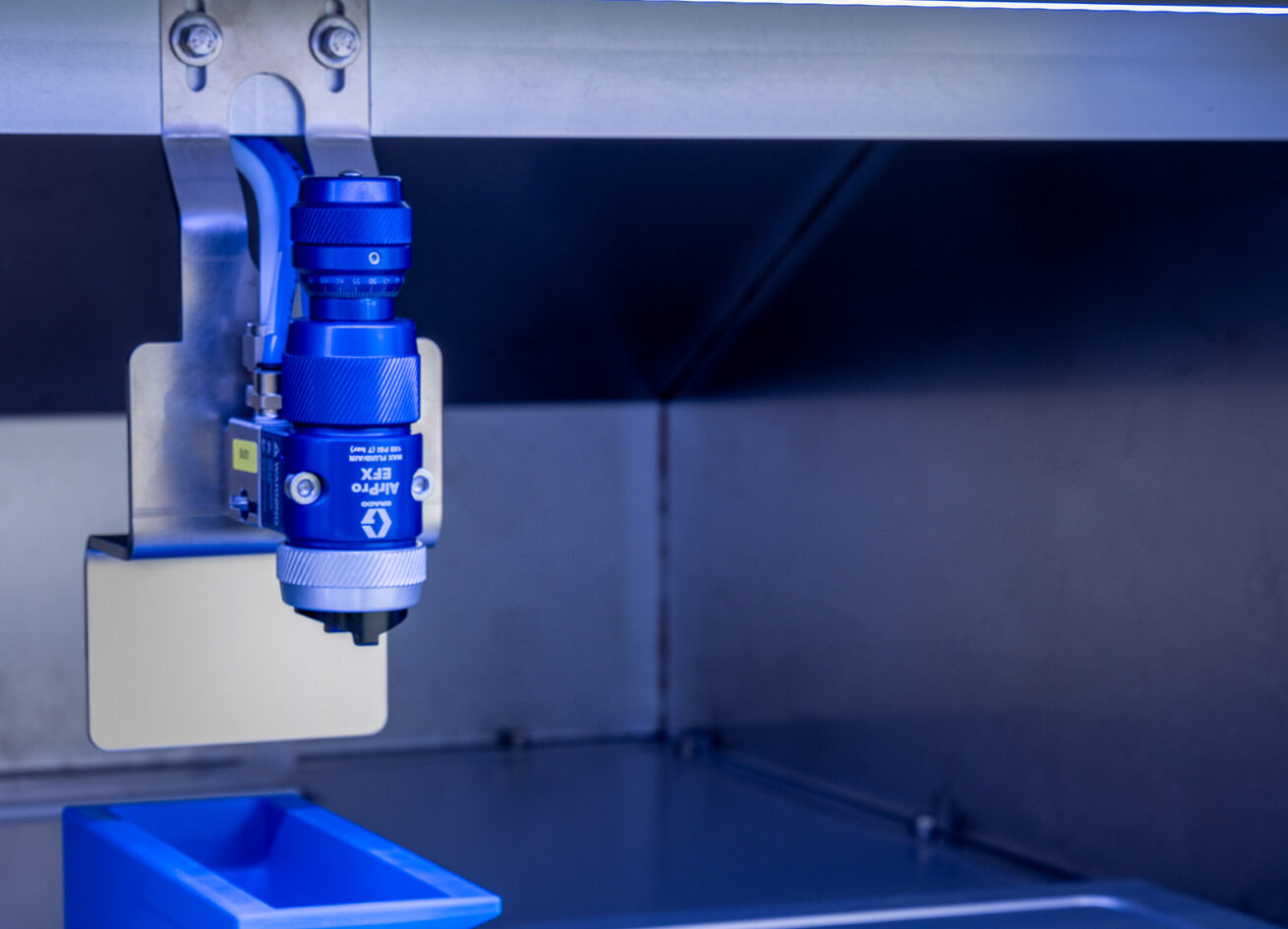

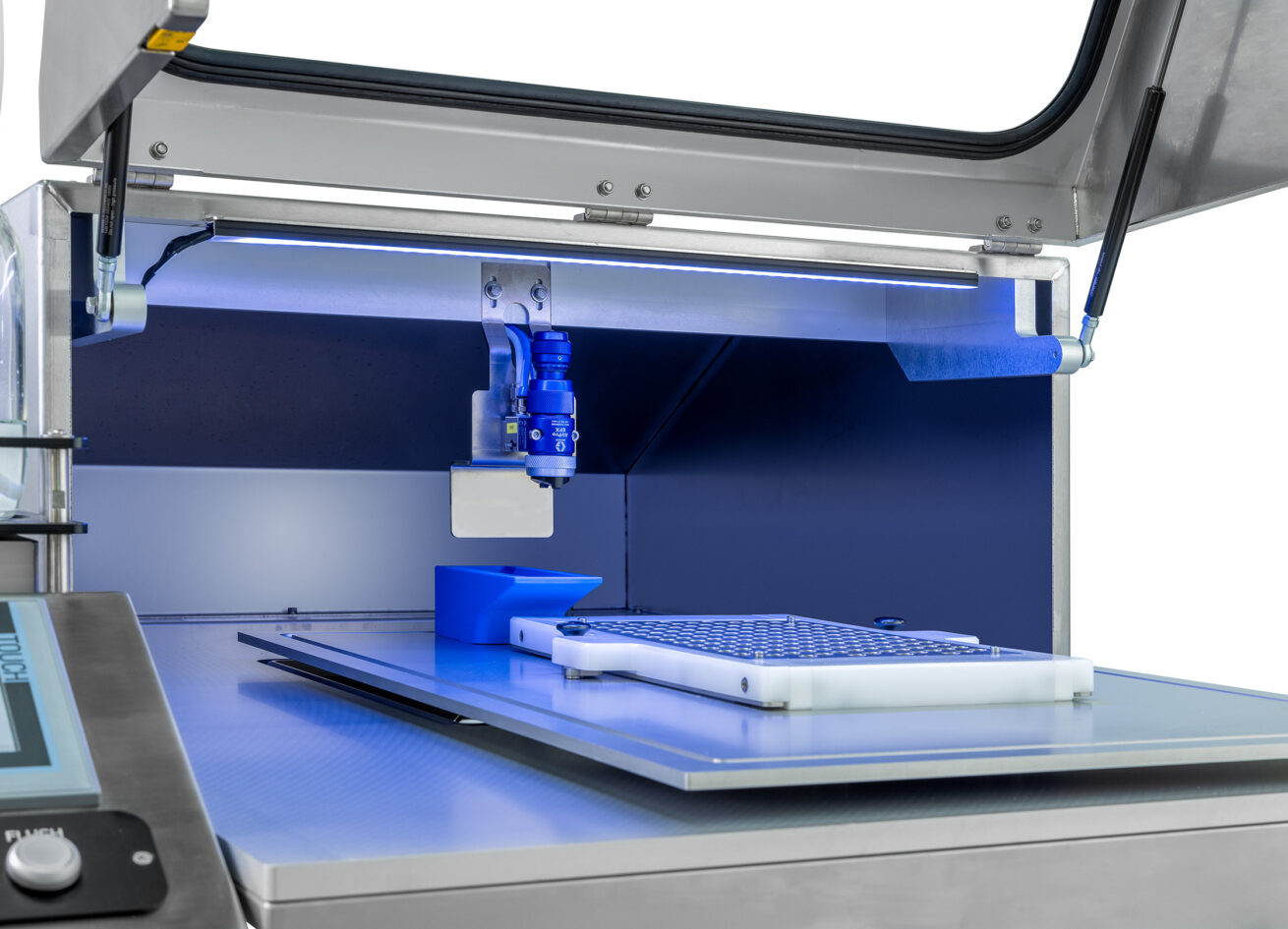

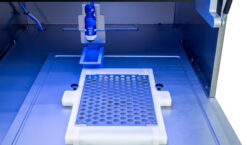

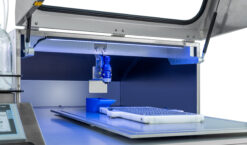

The Spraycoater is equipped with two liquid reservoirs. One of these reservoirs contains the coating liquid, while the other contains the cleaning liquid. The products that need to be coated are placed by the operator in a tray (also known as a product carrier) and then placed in the machine. The operator starts the coating cycle using a simple HMI.

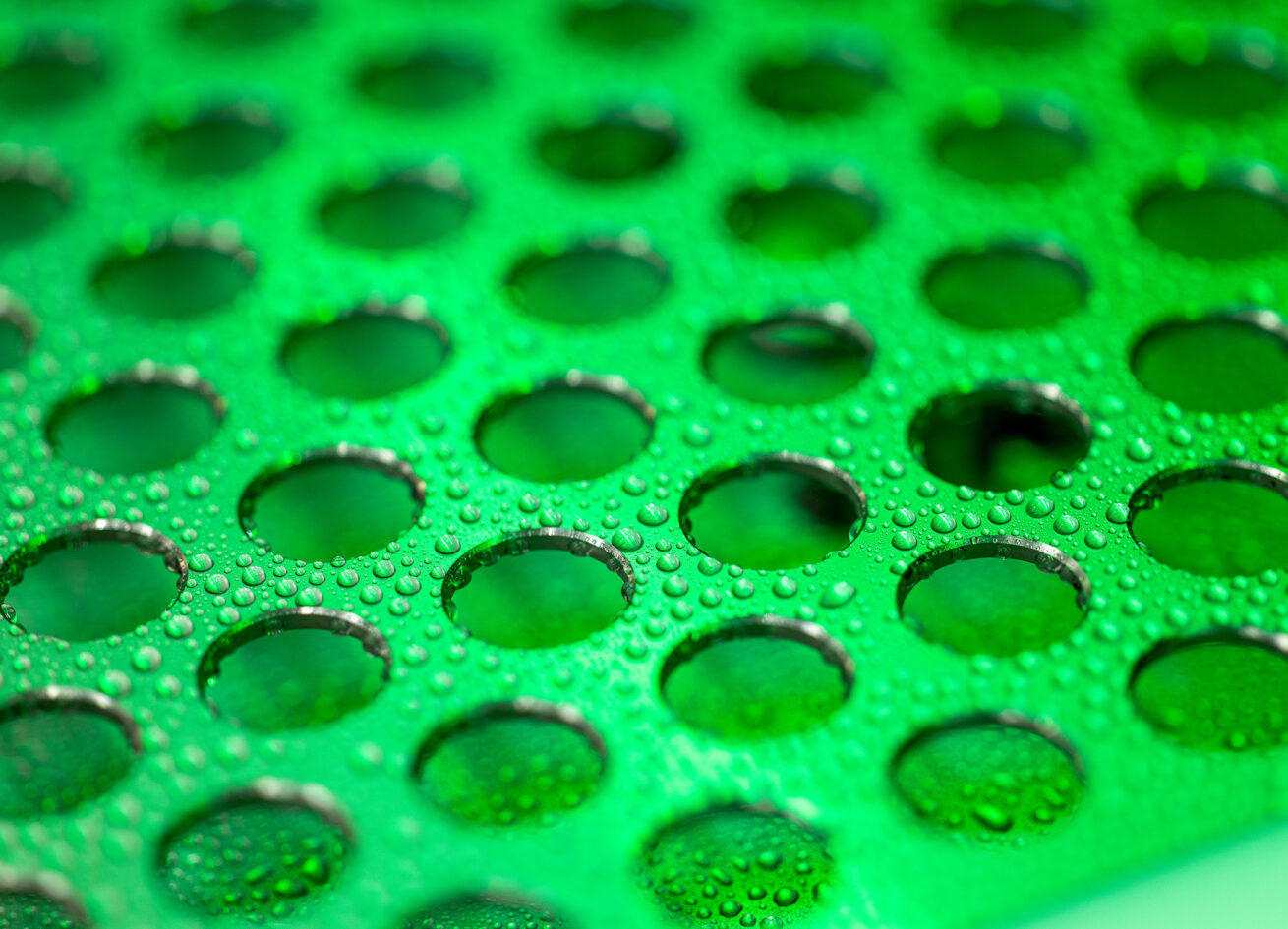

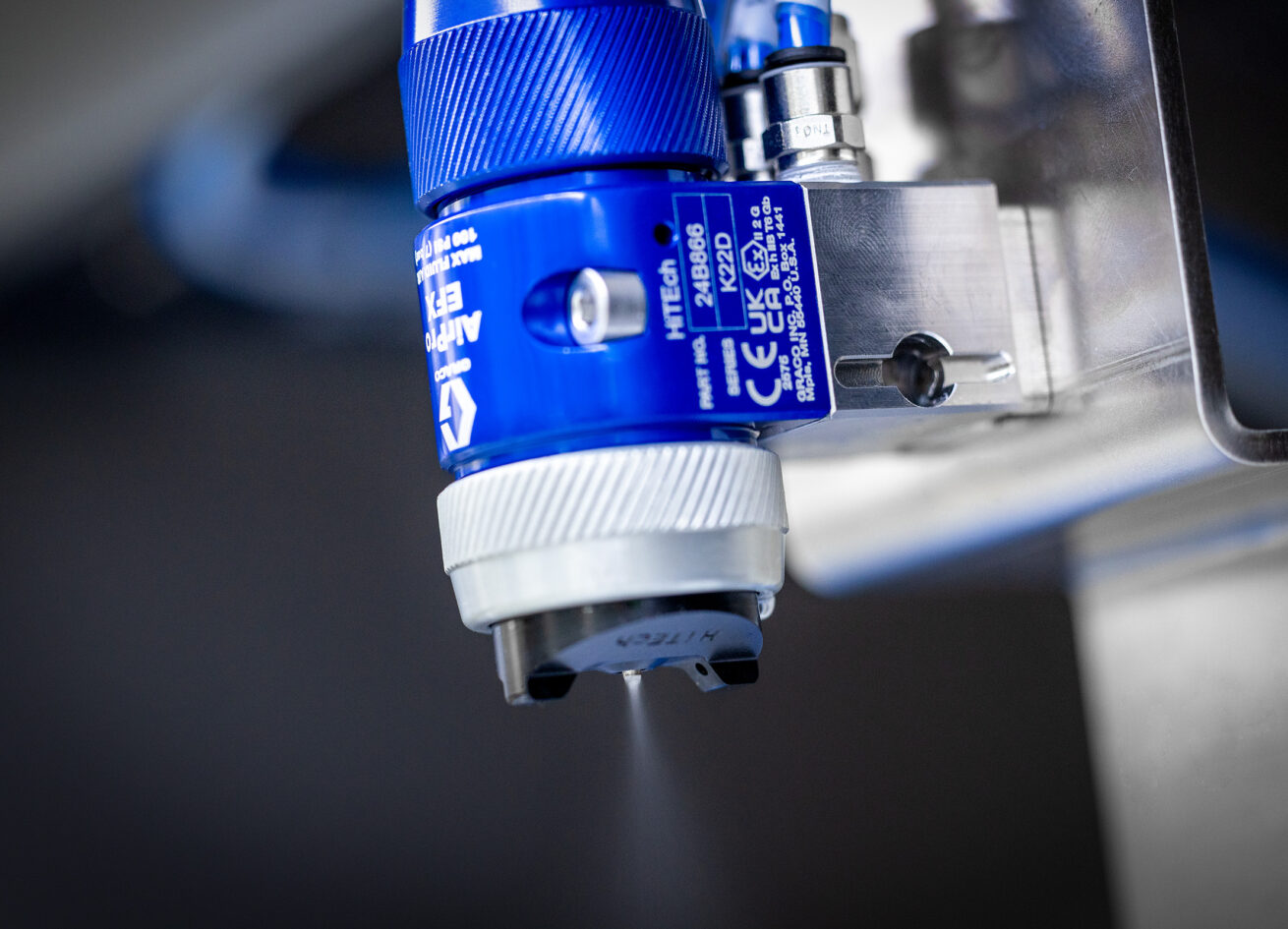

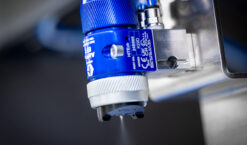

When the cycle is initiated, a large syringe pump draws a predefined amount of the appropriate liquid from the liquid reservoir. This liquid is then sprayed from the top onto the product, following a pre-set grid pattern. Using a specific product carrier prevents the coating liquid from reaching the bottom of the products.

Cleaning and Safety

In the medical and pharmaceutical industry, safety and a sterile environment are of utmost importance. Therefore, several features have been incorporated into this machine to meet both requirements. Firstly, an extraction system is integrated into the machine. This system ensures that the mist that does not land on the products to be coated is extracted, preventing a buildup of a large amount of explosive or flammable mist inside the machine.

The machine stops automatically if this system is not operational. Additionally, the operator can choose to clean the machine after each batch, following a predefined program. The operator simply needs to press a button to initiate this process. If this is not done frequently enough or within a certain timeframe, the machine will do this automatically.

Spraycoater Specifications

- High mix, low volume

- Suitable for flammable and explosive liquids

- Very precise quantity of liquid

- Semi-automatic cleaning

- Coats up to 276 products simultaneously

- Siemens control

- Status indication with LED panels per station

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)