The new process

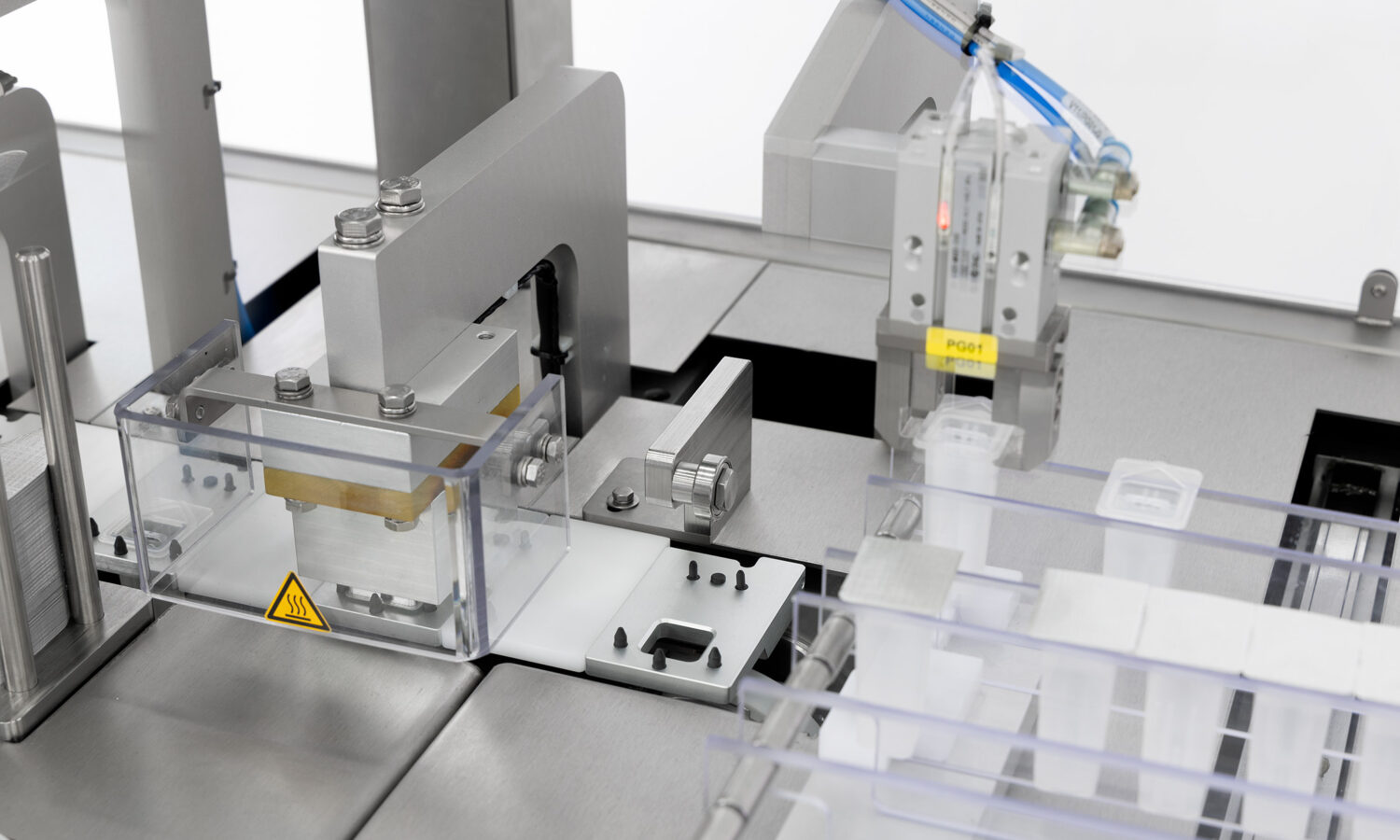

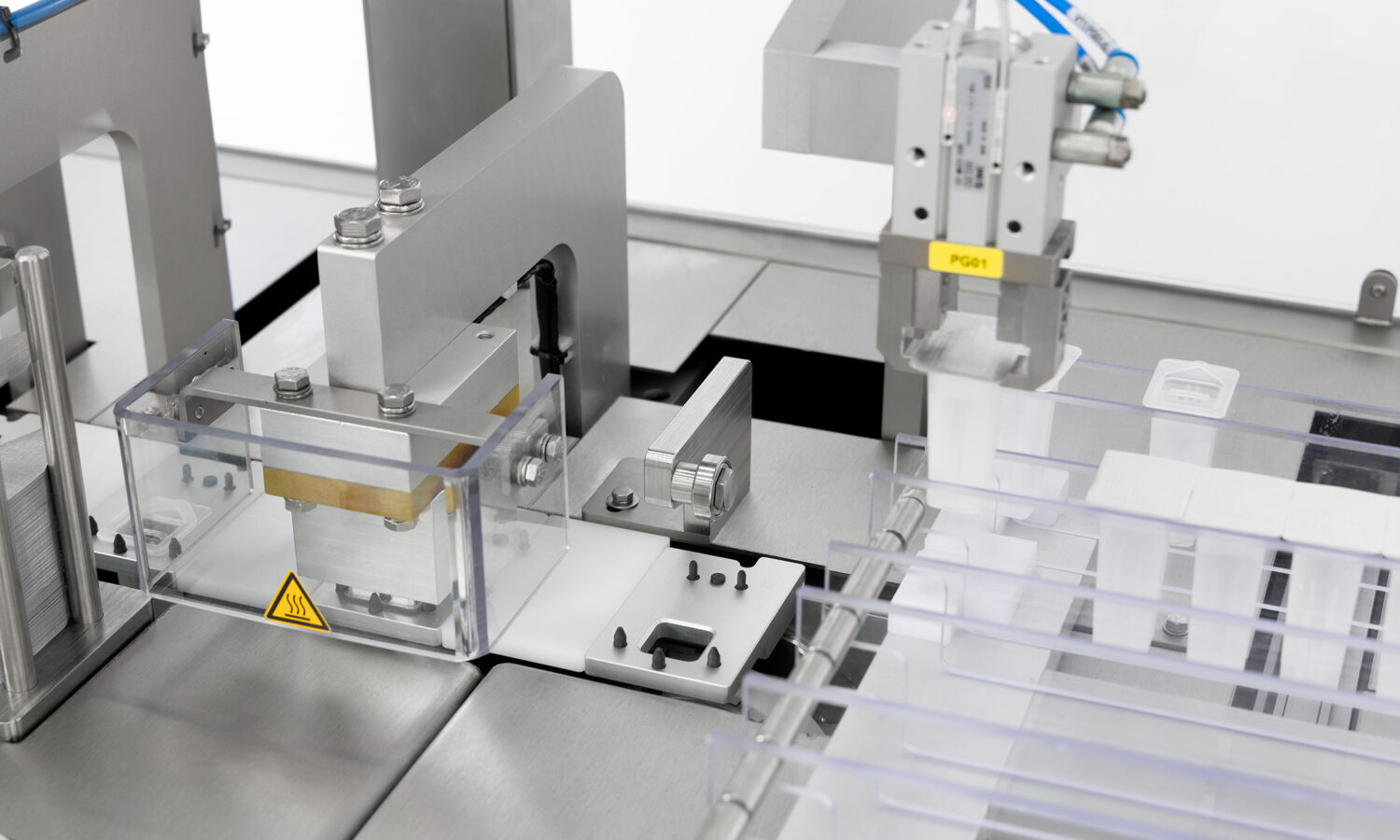

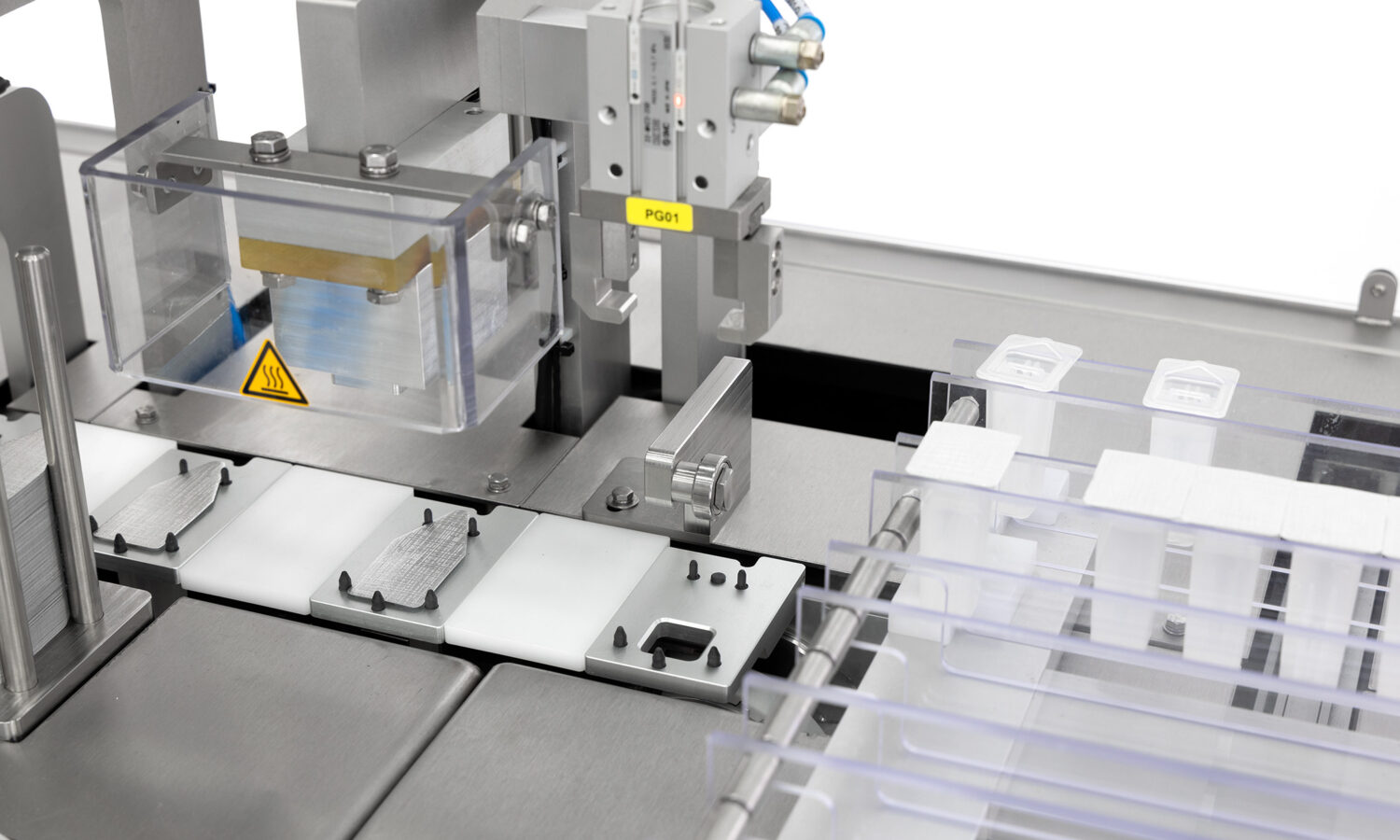

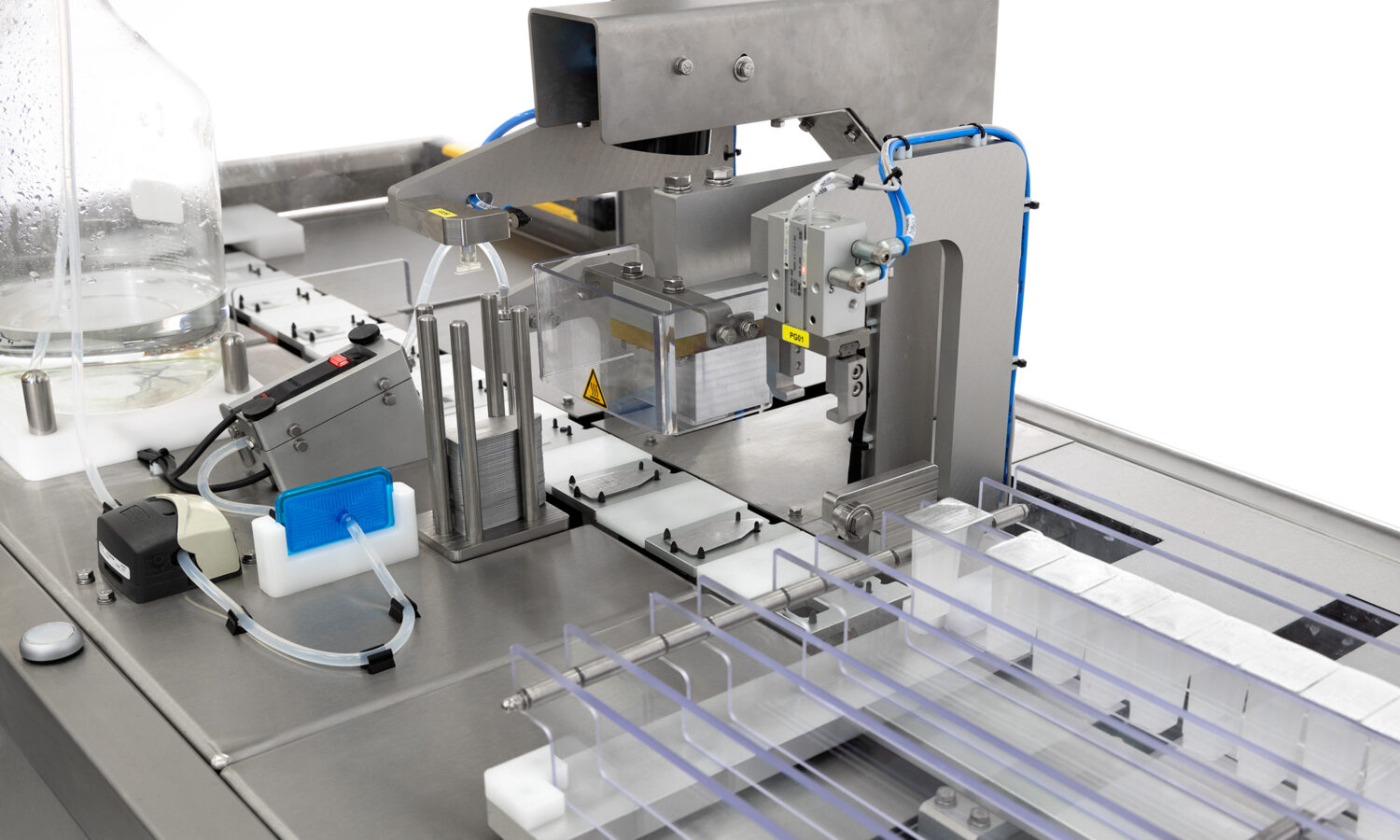

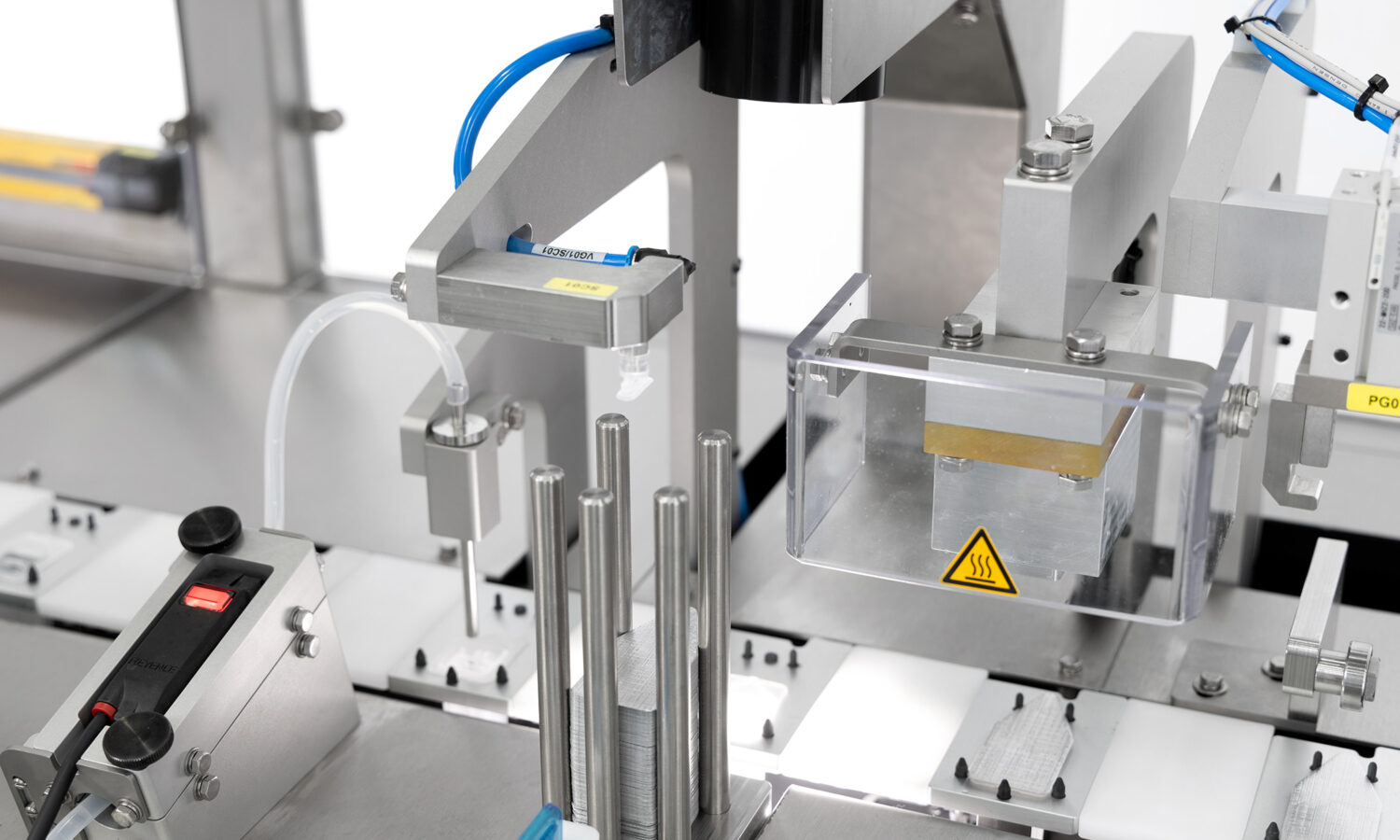

Operators check the intraocular lenses beforehand and then place them in the containers. These containers are then placed in the machine so they can be filled with liquid. Several Vision checks make sure that the container is filled with the right amount of liquid and there are no drops on the edge. This keeps both the machine and the sealing edge dry – which is important for the next step: sealing.

The pre-cut aluminium lids are separated and placed on top of the container, after which it’s sealed. After sealing, the machine places the container in a rack. Rejected products are placed in a separate area of the rack so they don’t get mixed up and the quality of your products is guaranteed.

Specifications

- Completely sterile operation

- Comprehensive quality control using a Vision System

- Fully tailor-made

- Small footprint

Requesting assets

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields