Here’s how it works

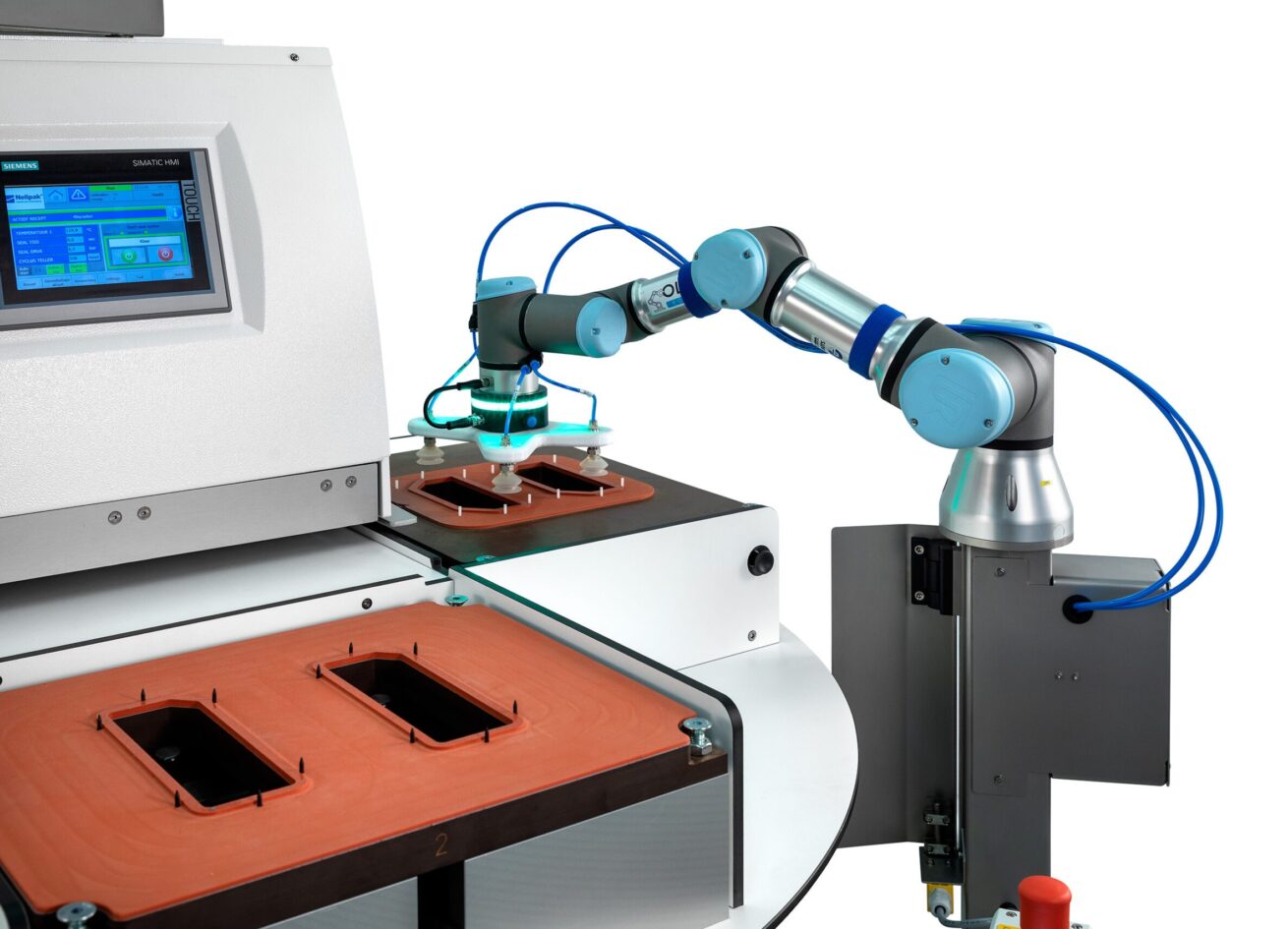

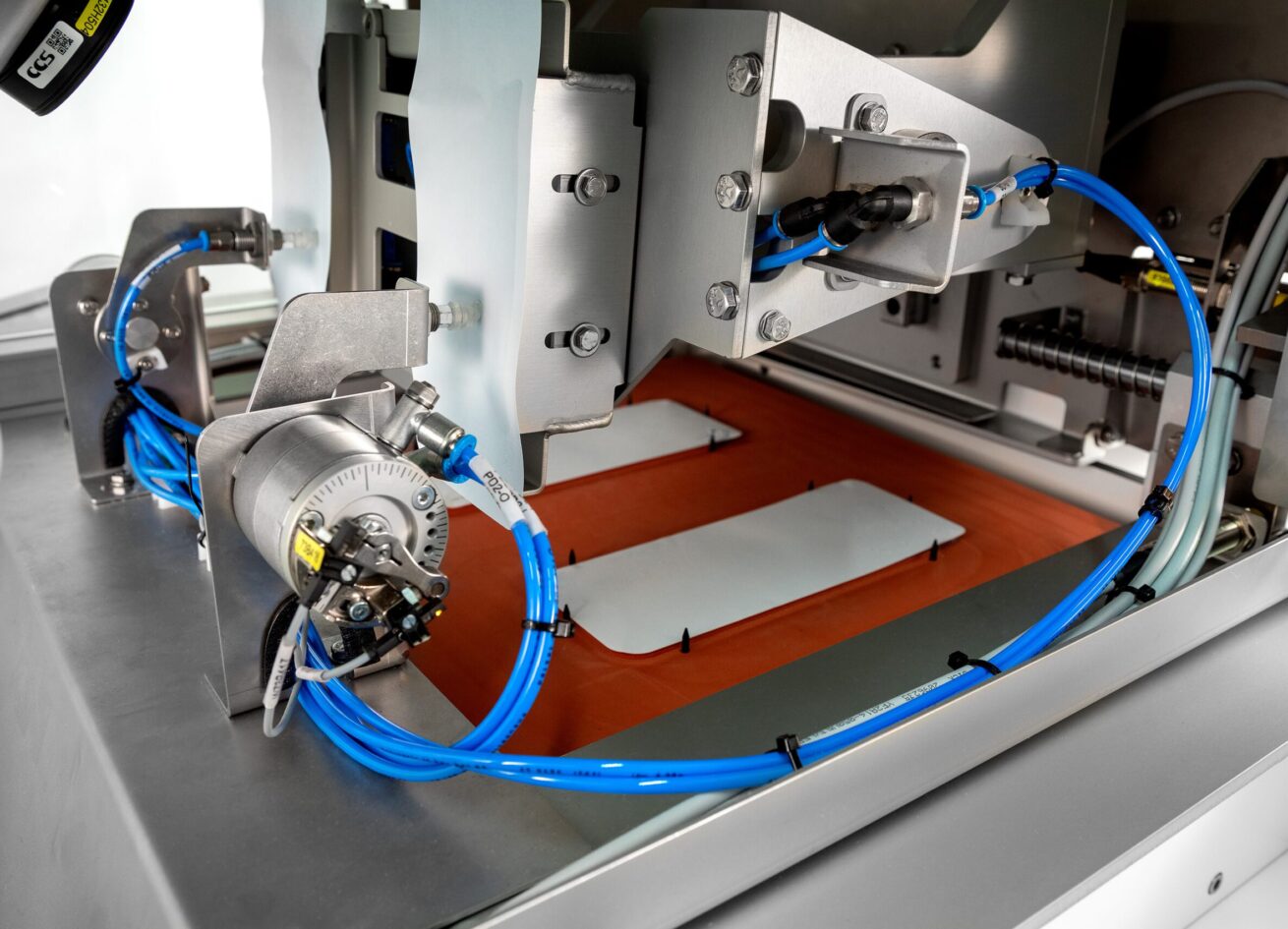

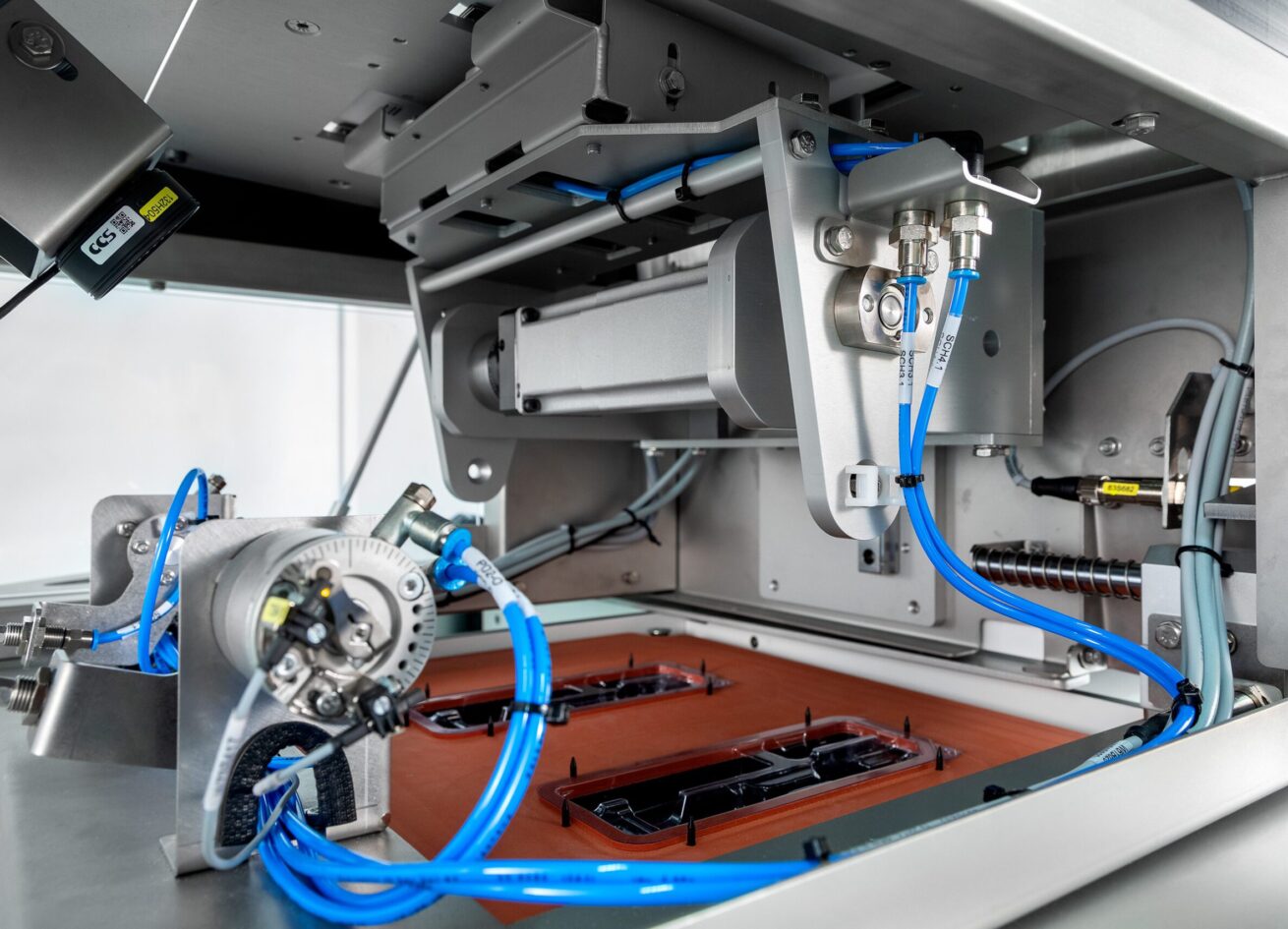

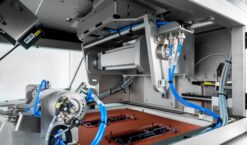

An operator places filled blisters in the sealing mould. The first station checks the presence of the products with a Vision camera, after which it separates a lid. The machine then checks for duplicate lids with suction cups. If everything’s in order, the lid’s placed on top of the blister. Another Vision camera checks whether the lids have been placed correctly.

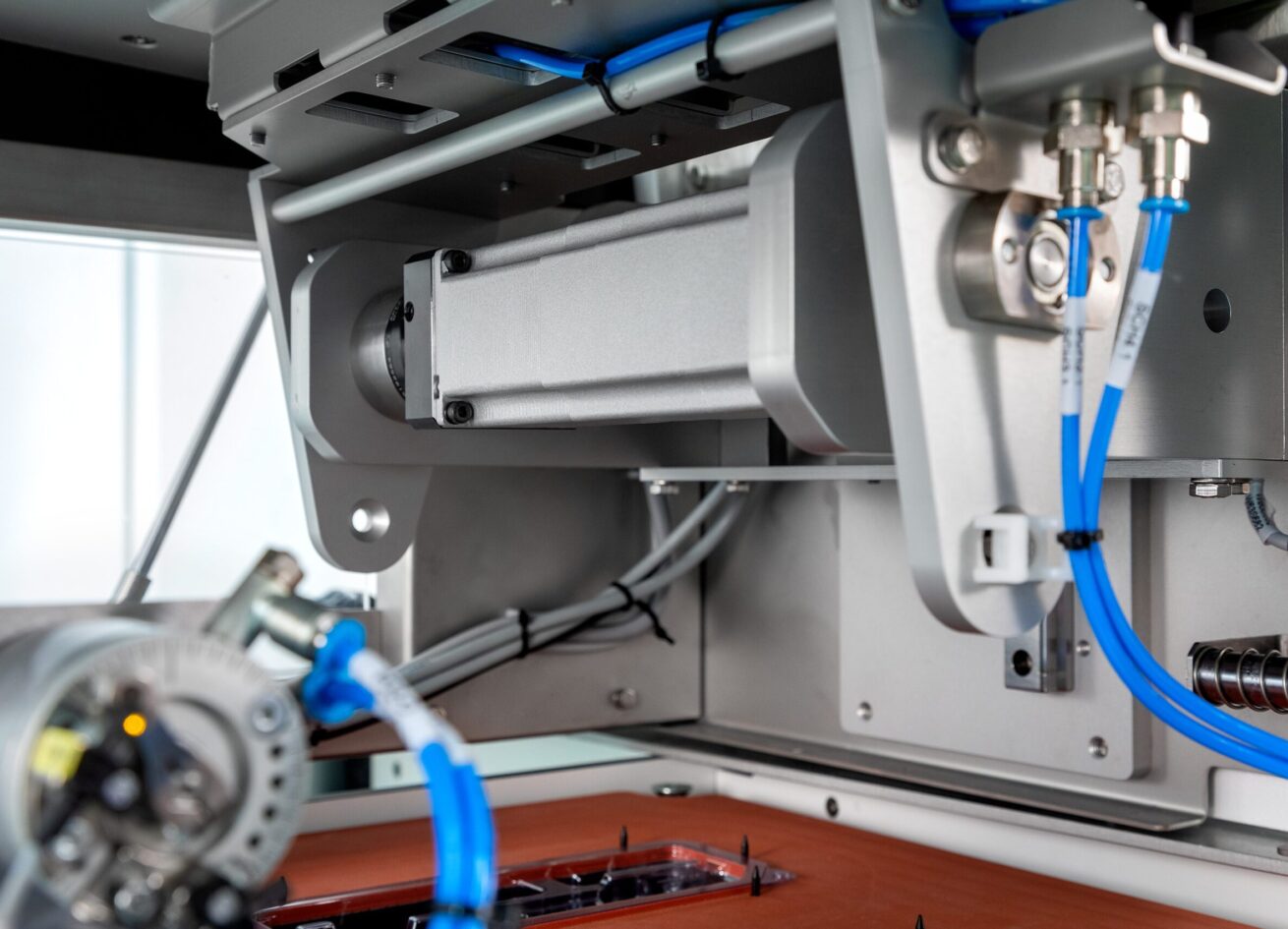

The next station seals the blister and checks the seal’s strength, temperature, and the sealing time. This process already existed within the original machine and required no changes.

In the fourth and final station, the cobot removes the filled and sealed blisters from the machine and places them on, for example, a conveyor belt.The machine is fully CE-certified, meaning it meets all set requirements. GTE takes responsibility for the safety of the entire system.

Specifications

- Further automated existing machine from different manufacturer

- Based on customer’s wishes

- Increases efficiency

- Saves costs

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)