Syringe assembling machine operation

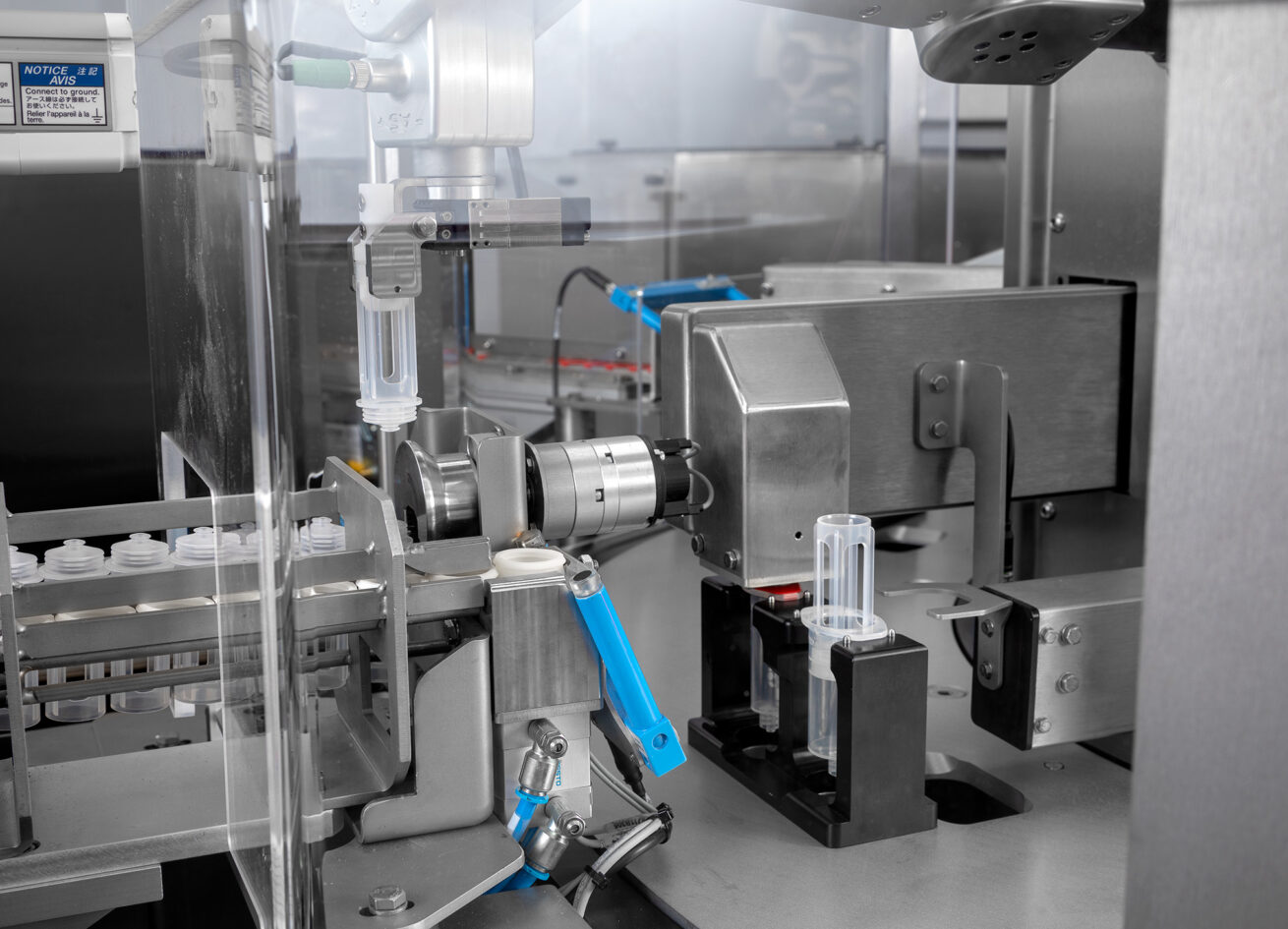

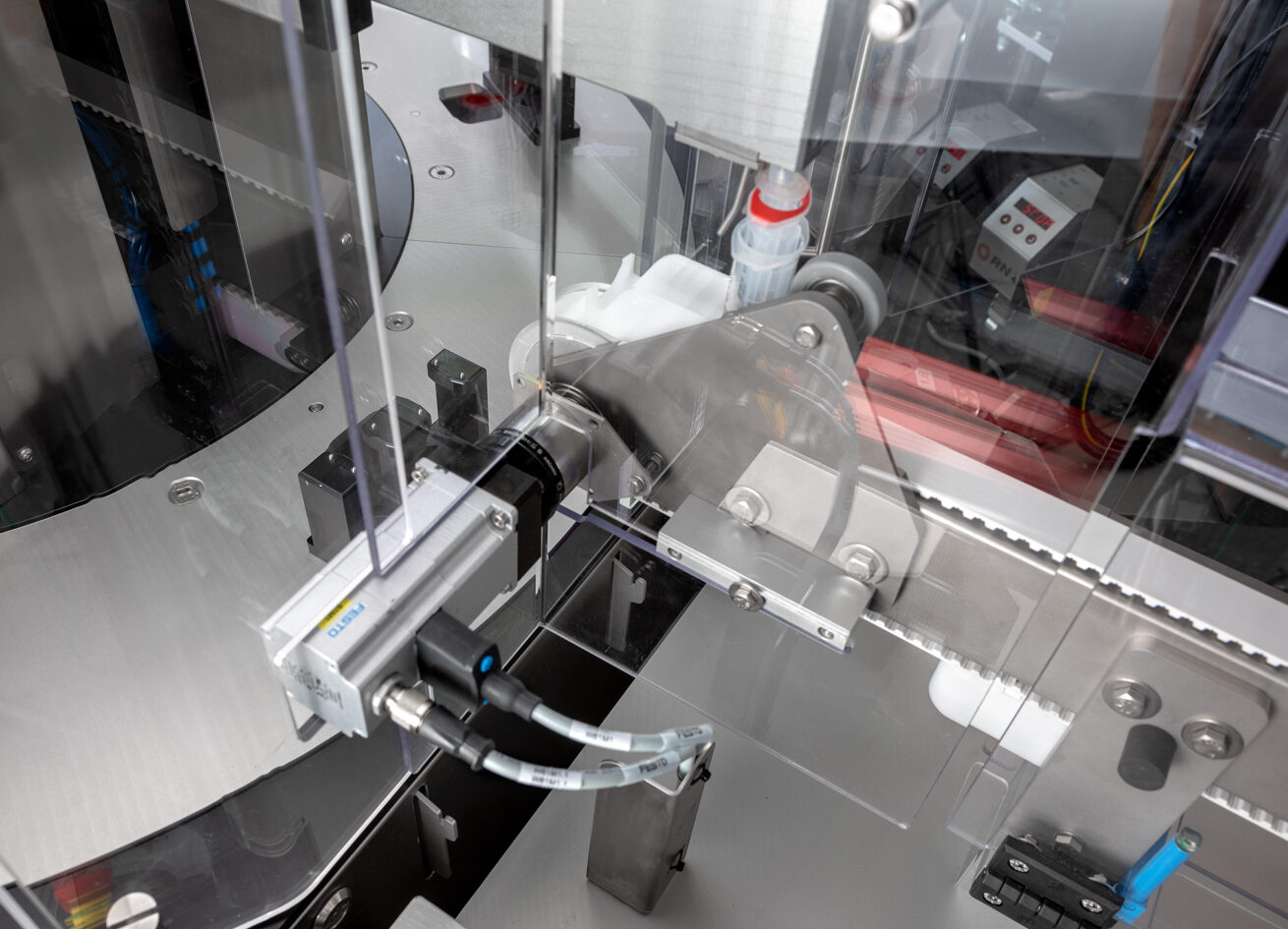

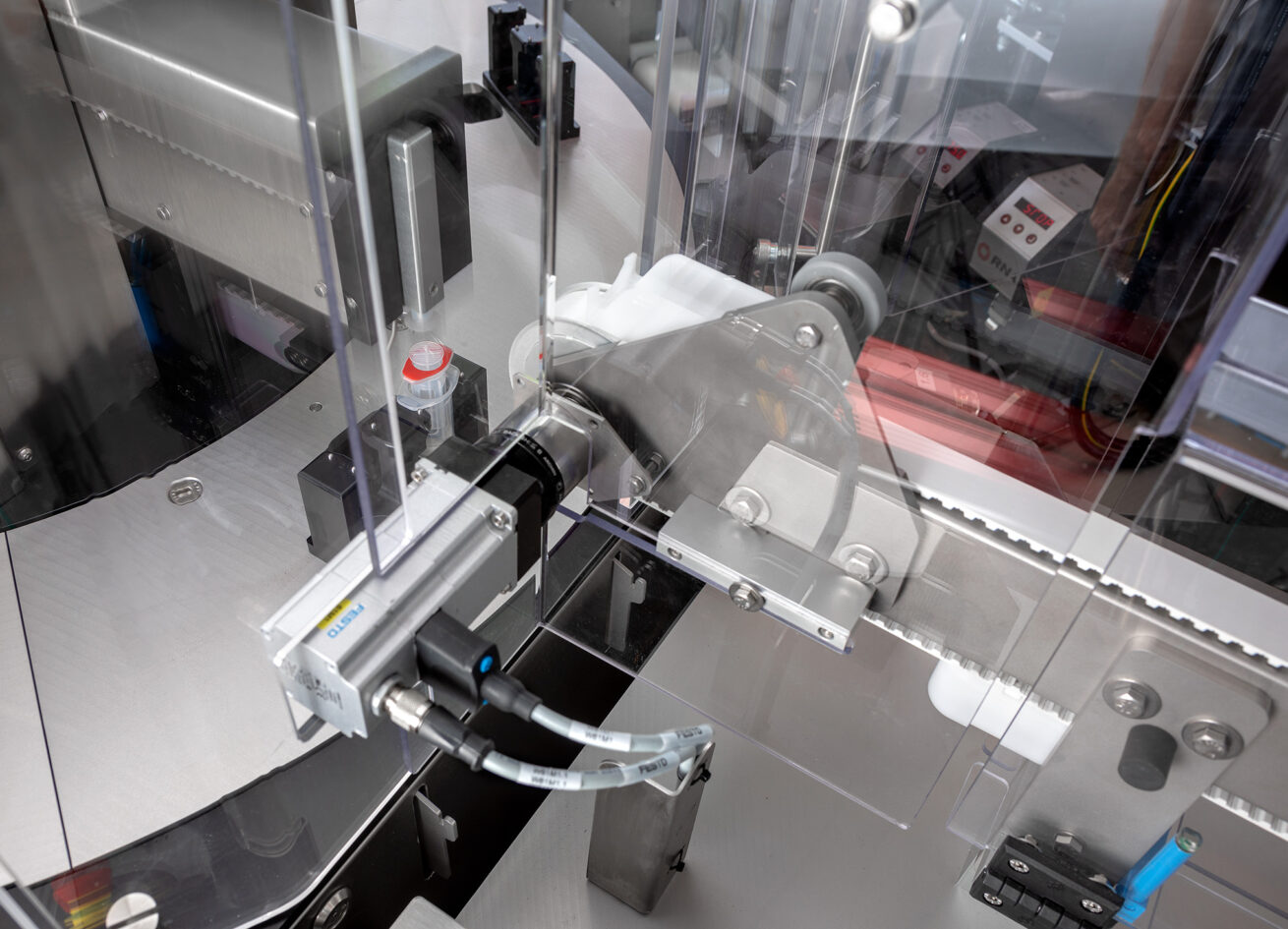

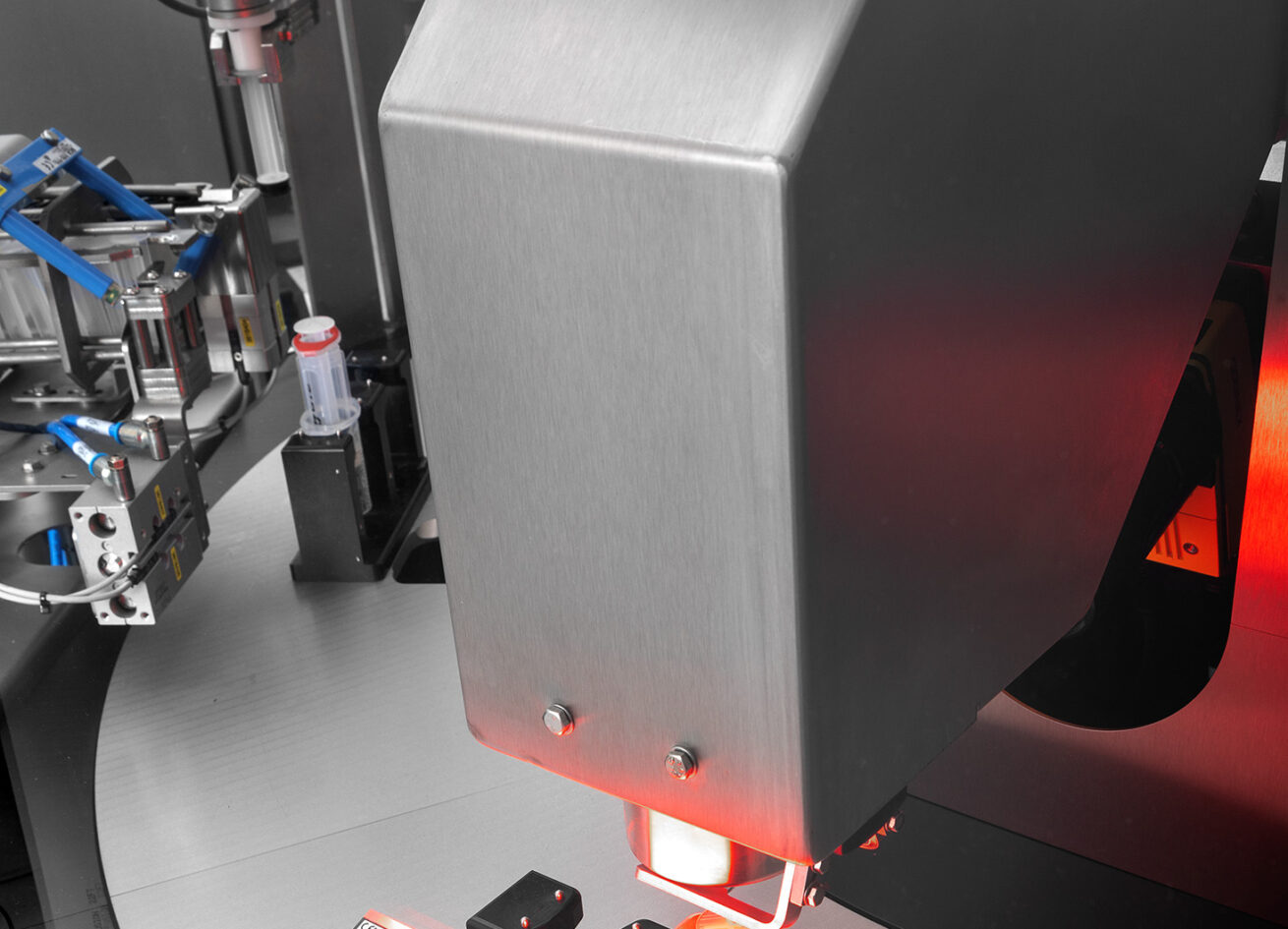

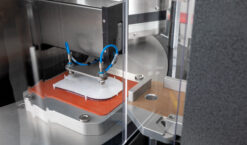

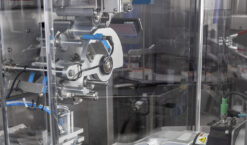

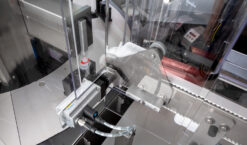

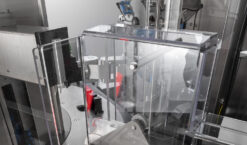

First, the two different cylinders of the syringe are fed into the assembly machine via two vibratory fillers. These two cylinders are both digitally printed with logos and sizing. This is followed by the first Vision Check, focused on the quality of the printing. The rubber plungers and plunger rods are assembled and then inserted into the cylinders with Mecademic robots, which are supplied via vibratory fillers. The double syringe is now assembled, after which another Vision Check takes place. This one checks that all components are present and that the syringes are deep enough.

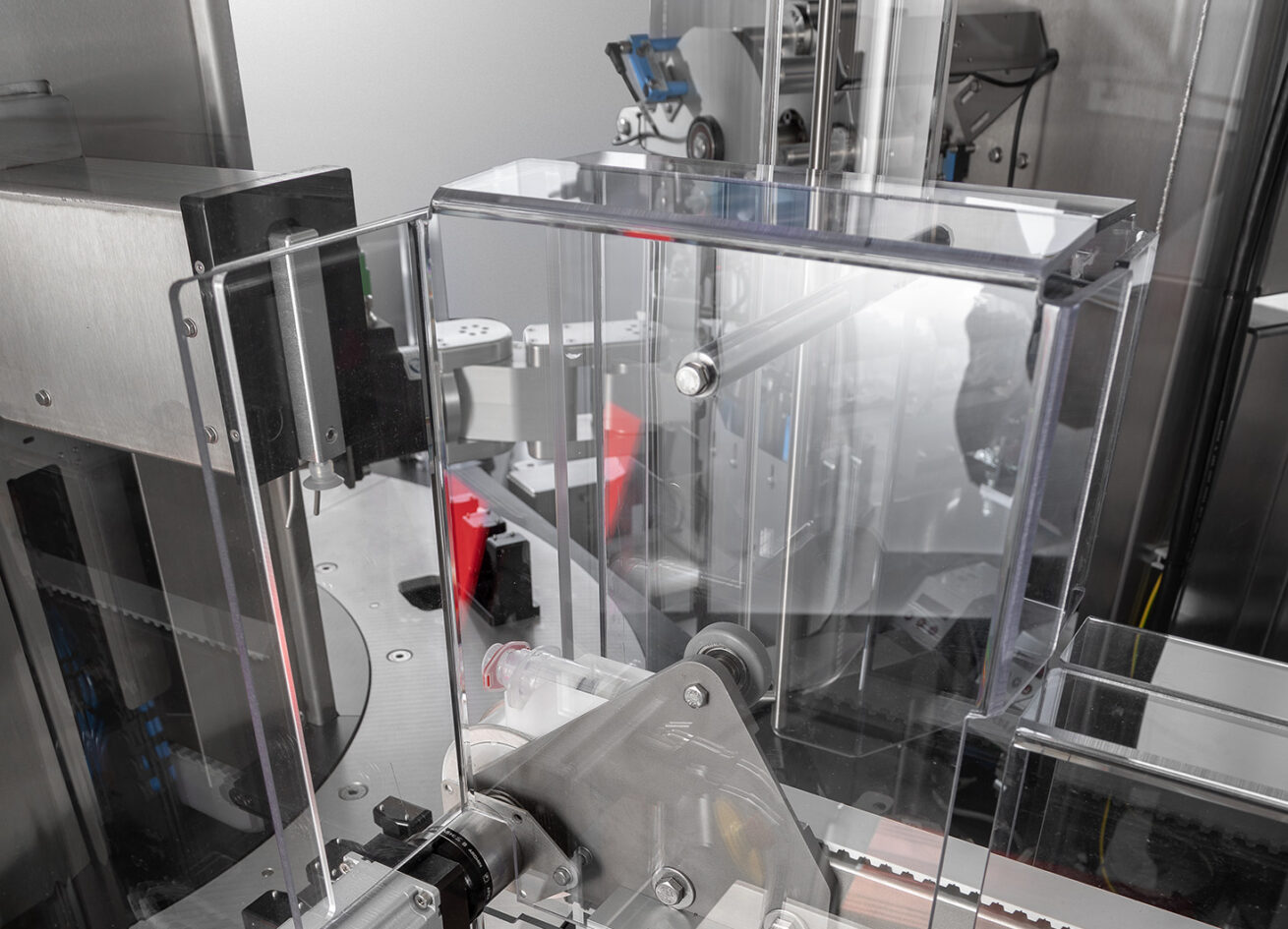

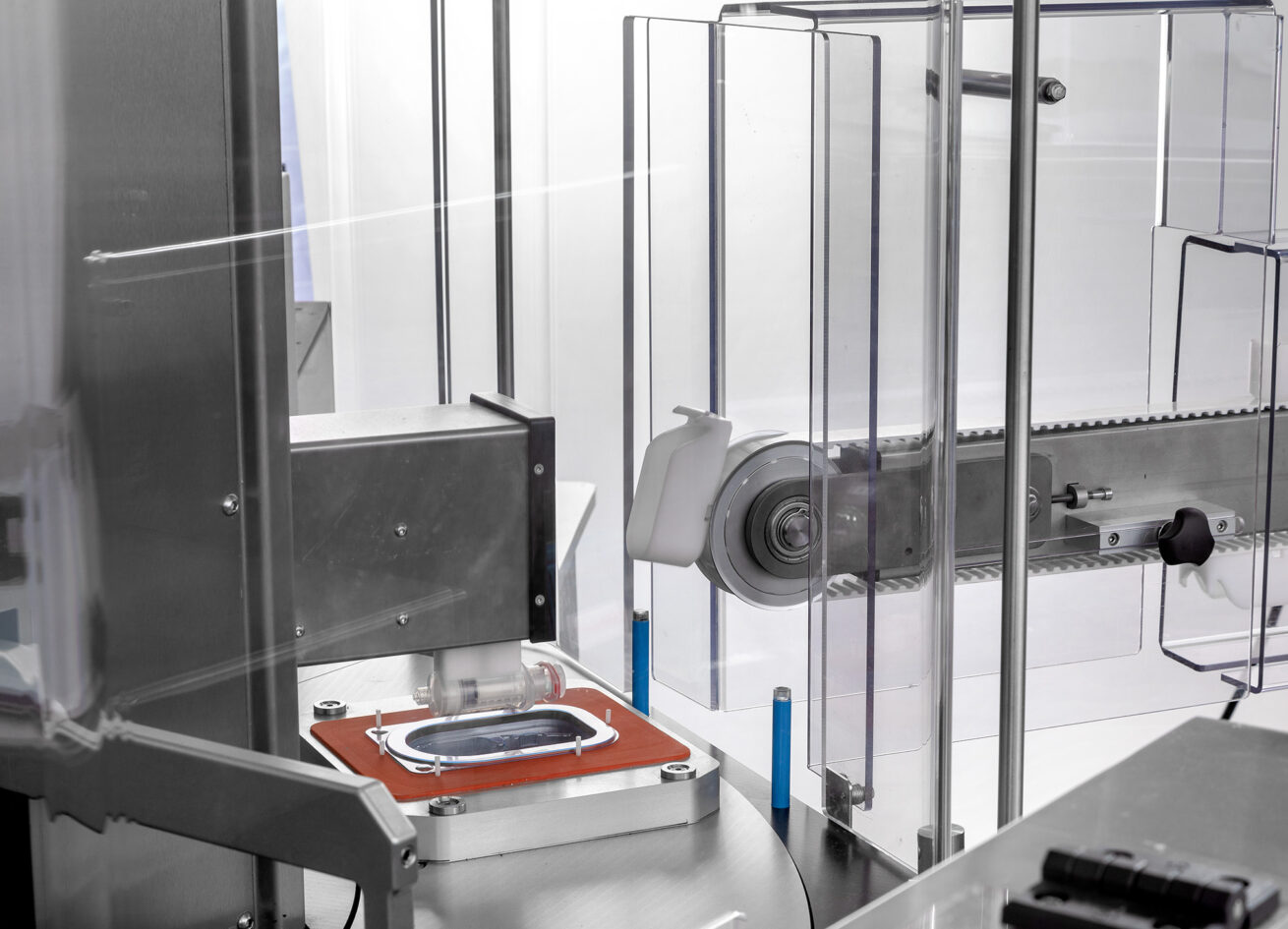

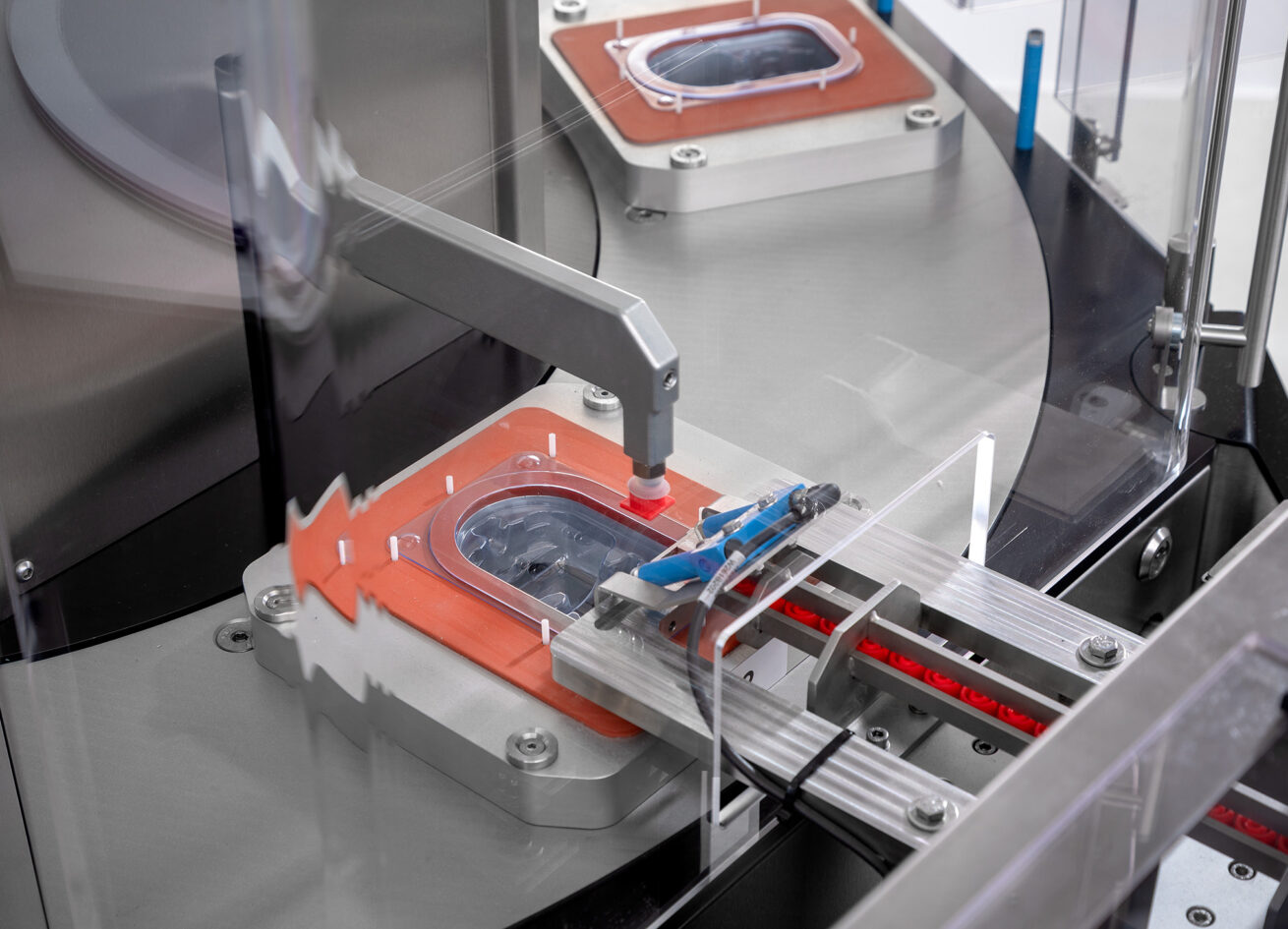

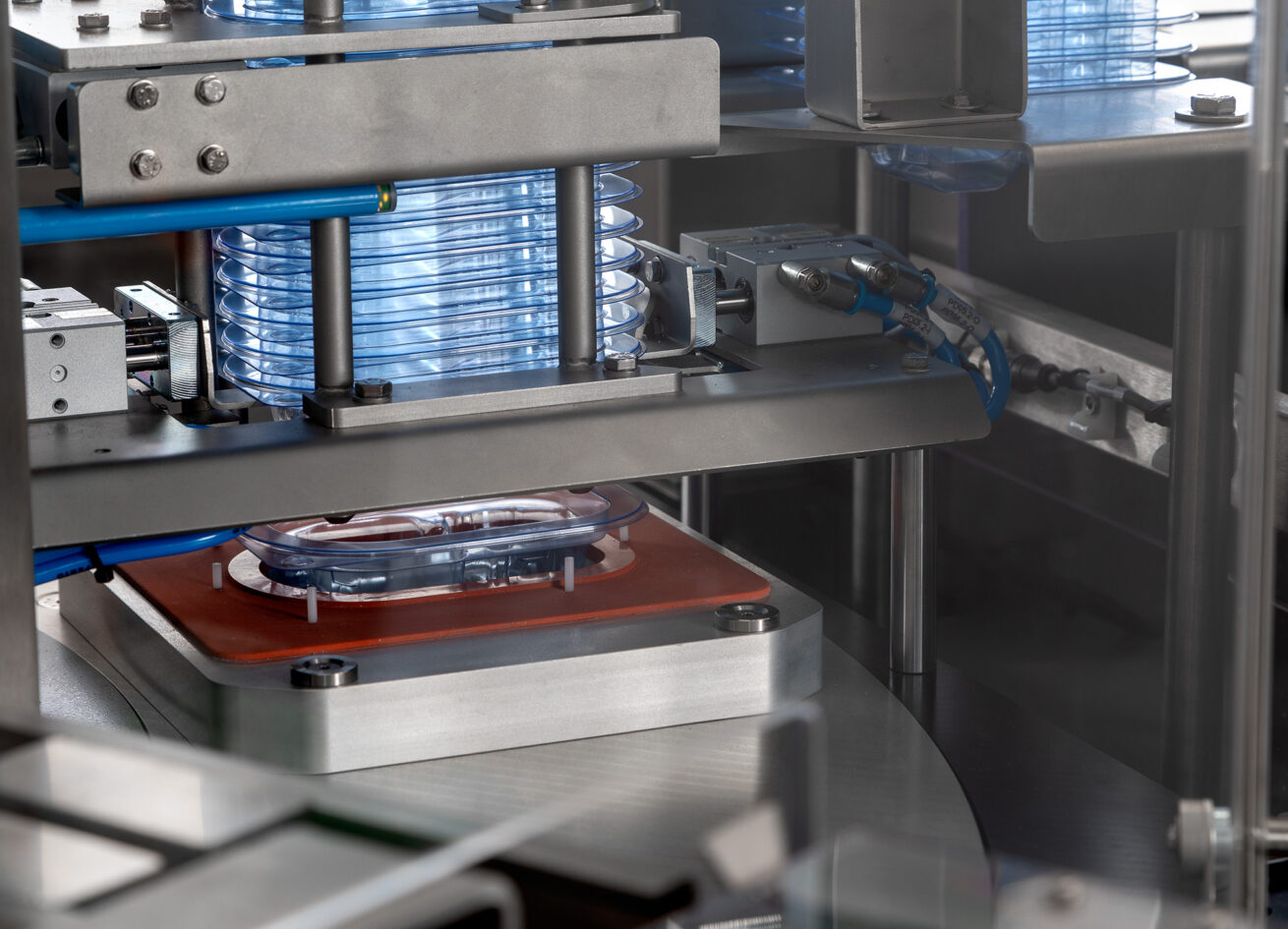

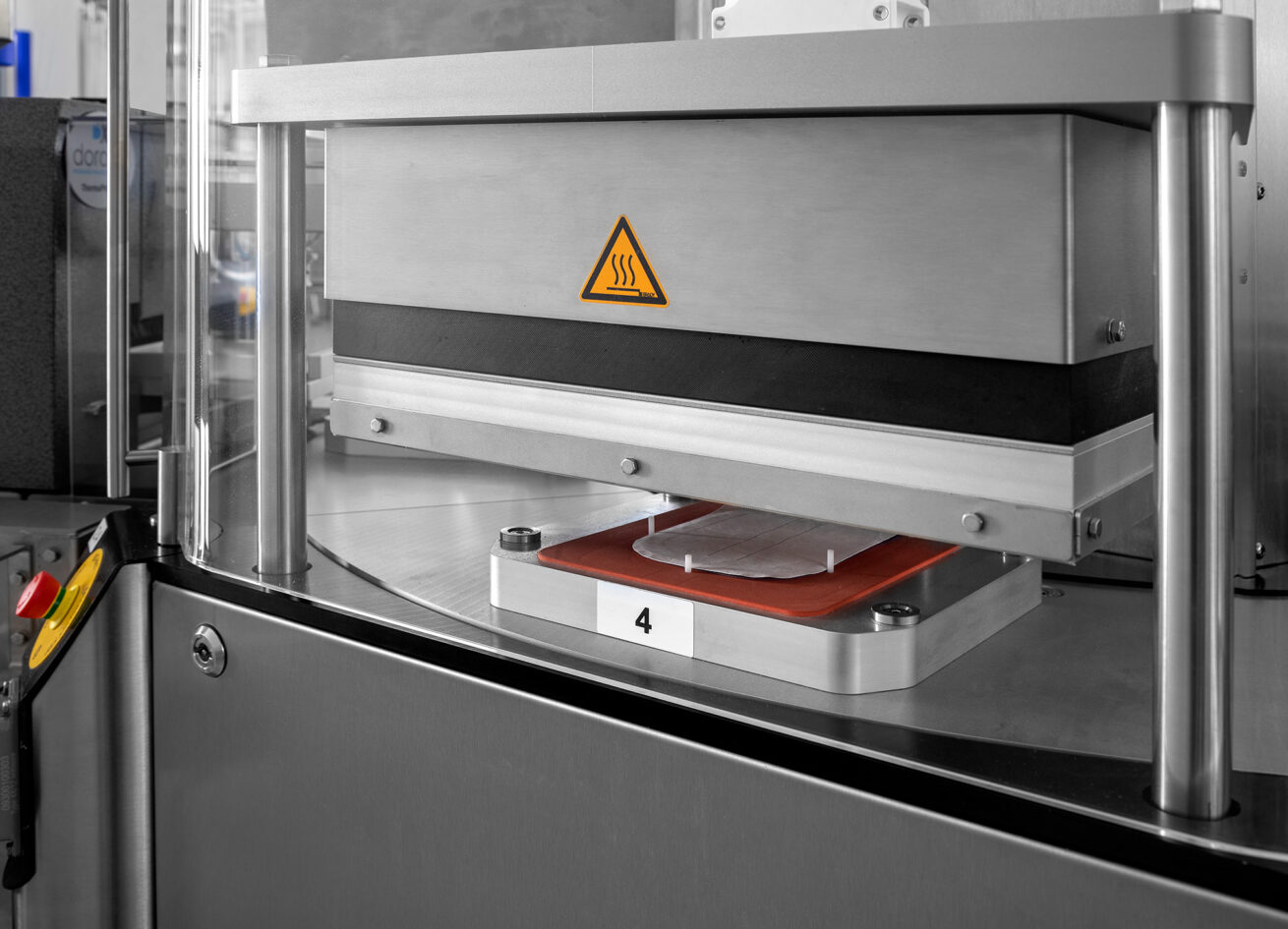

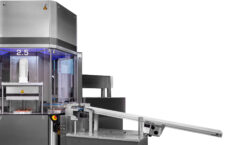

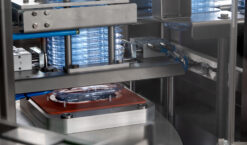

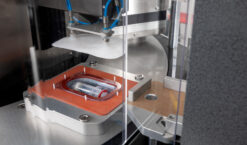

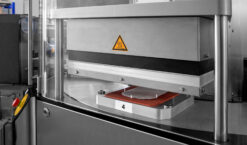

After assembly is complete, the syringes are transported by conveyor belt to the automatic packing machine. This syringe assembling machine separates pre-formed blisters and places an additional component and a syringe in them. The machine checks, through a Vision System, that all products are in the blister. The Tyvek lid is printed with data and then placed on the blister. Finally, the machine checks that the lid has been placed correctly – if it is, the blister is sealed.

Specifications

- Based on LAP-C

- Total solution for printing, assembling, and packing syringes

- Ideal for high-mix, low-volume applications

- Quality control through the Vision System

- Turnaround time of about 10 seconds per syringe

- Possible to upgrade to 40 to 50 products per minute

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)