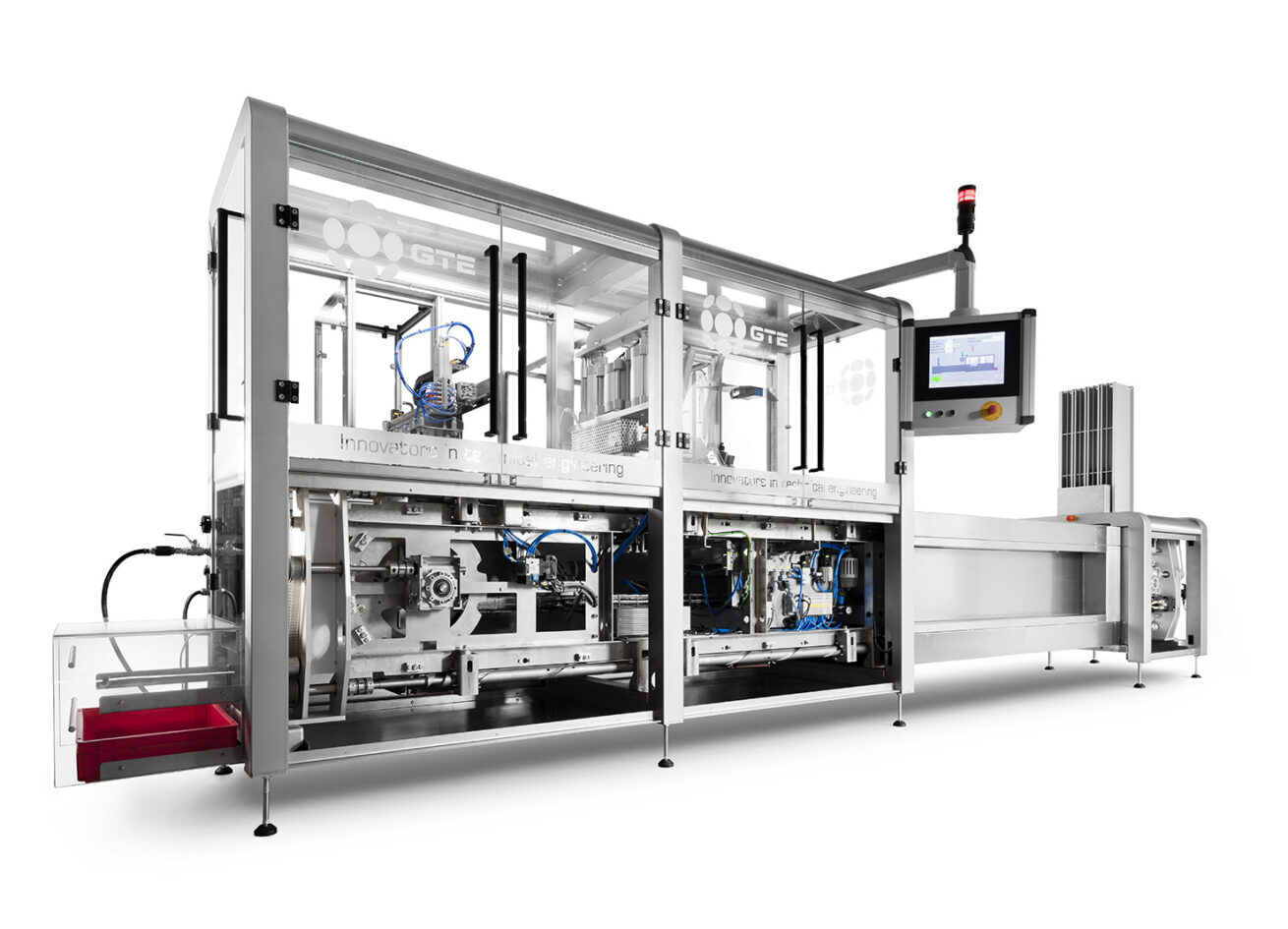

Flexibility without contamination

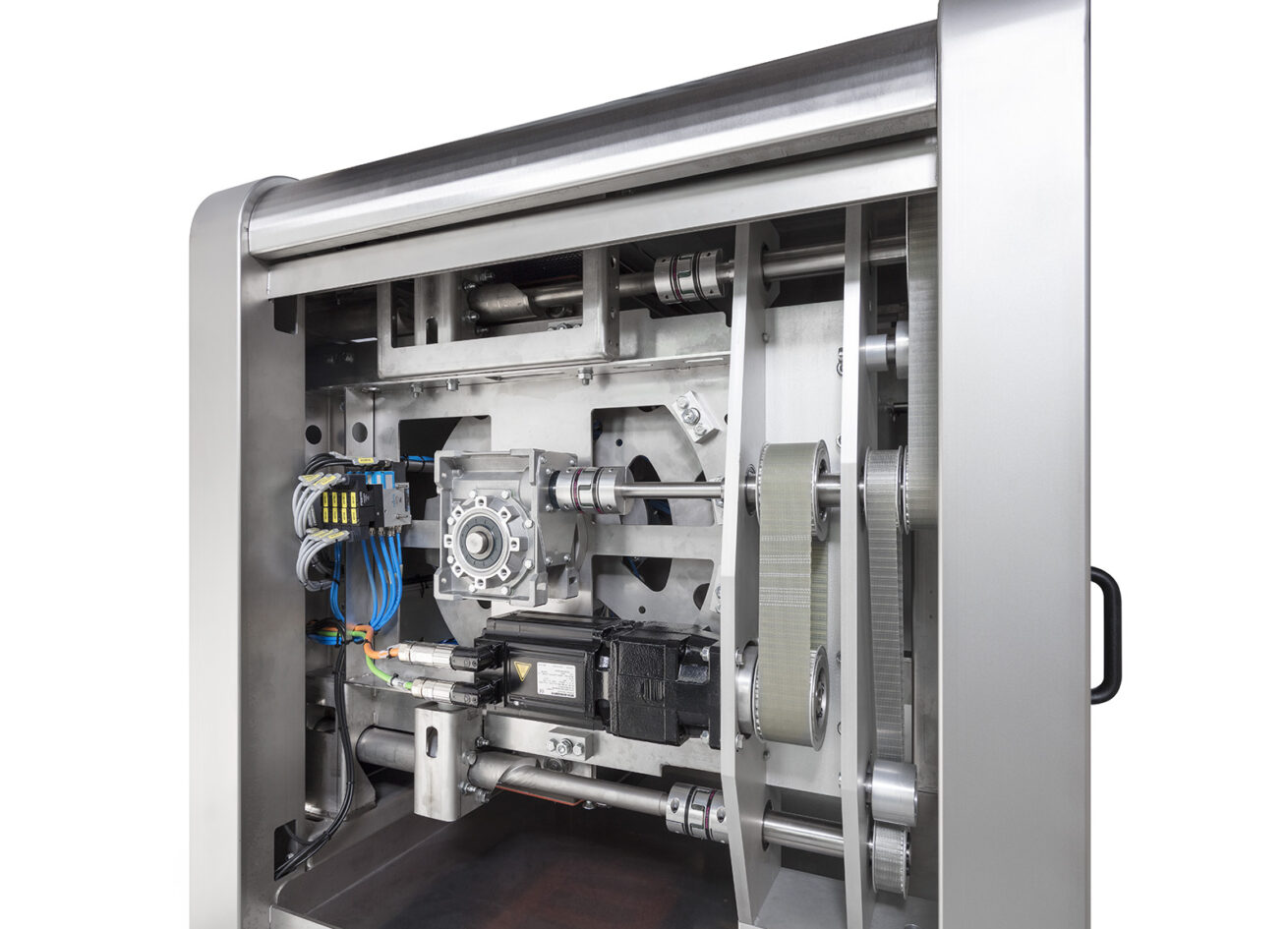

Blister moulds can be quickly swapped out when working with multiple different sizes. By, among other things, making sure that as many moulds as possible are used at the same time and there is no contamination from dust particles, the machine’s production process is fully 21 CFR 11 compliant. This safety requirement ensures that you can store as much data as possible digitally, while still monitoring its safety.

Specifications

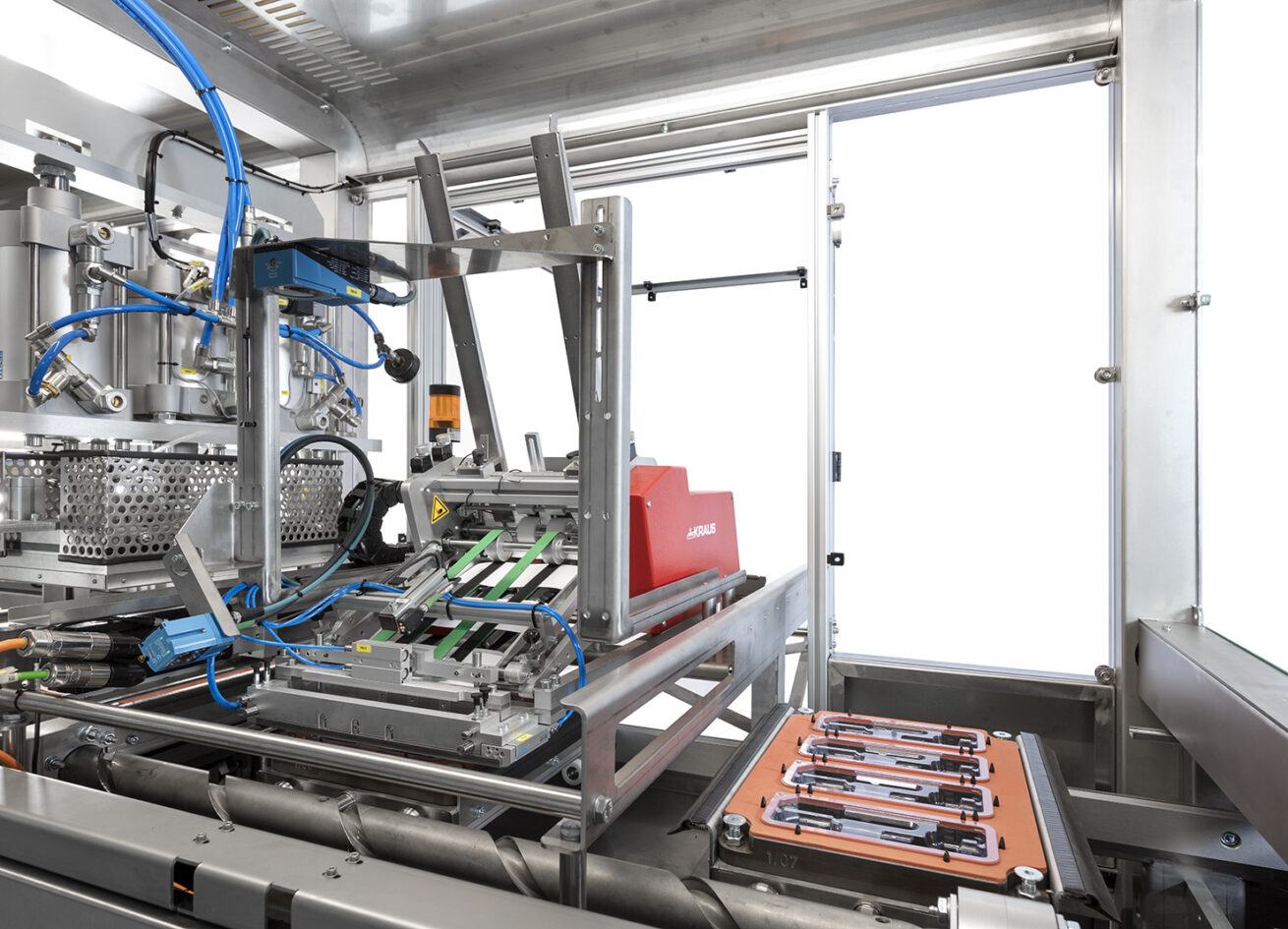

- Automatic placement of blisters from the warehouse

- Places lids on blisters, sealing with a heat seal

- Expanded features: printing and serialisation for additional control

- Reduces labour intensity

- Increases production capacity

- Lowers production costs

- Increases quality

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields