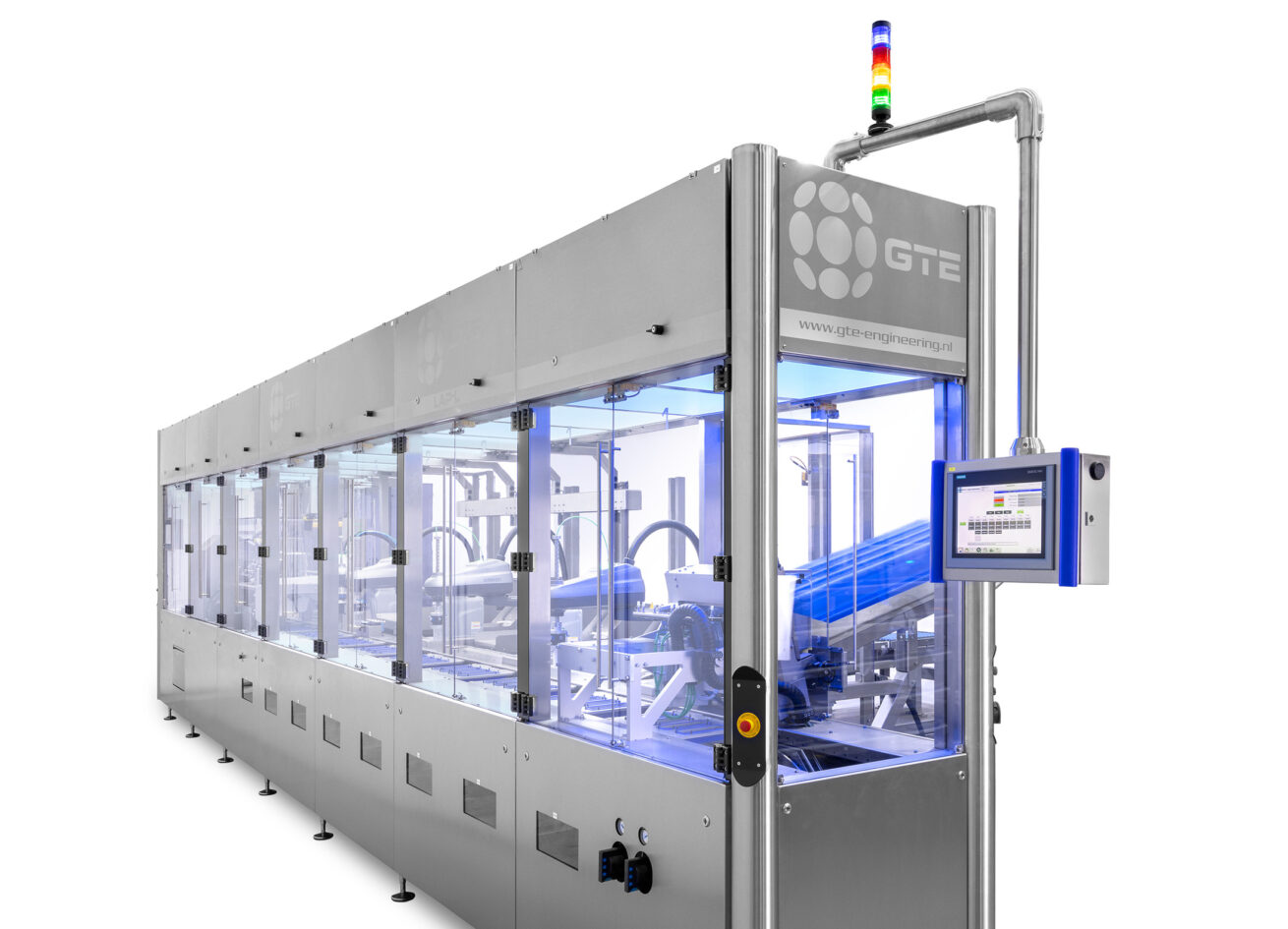

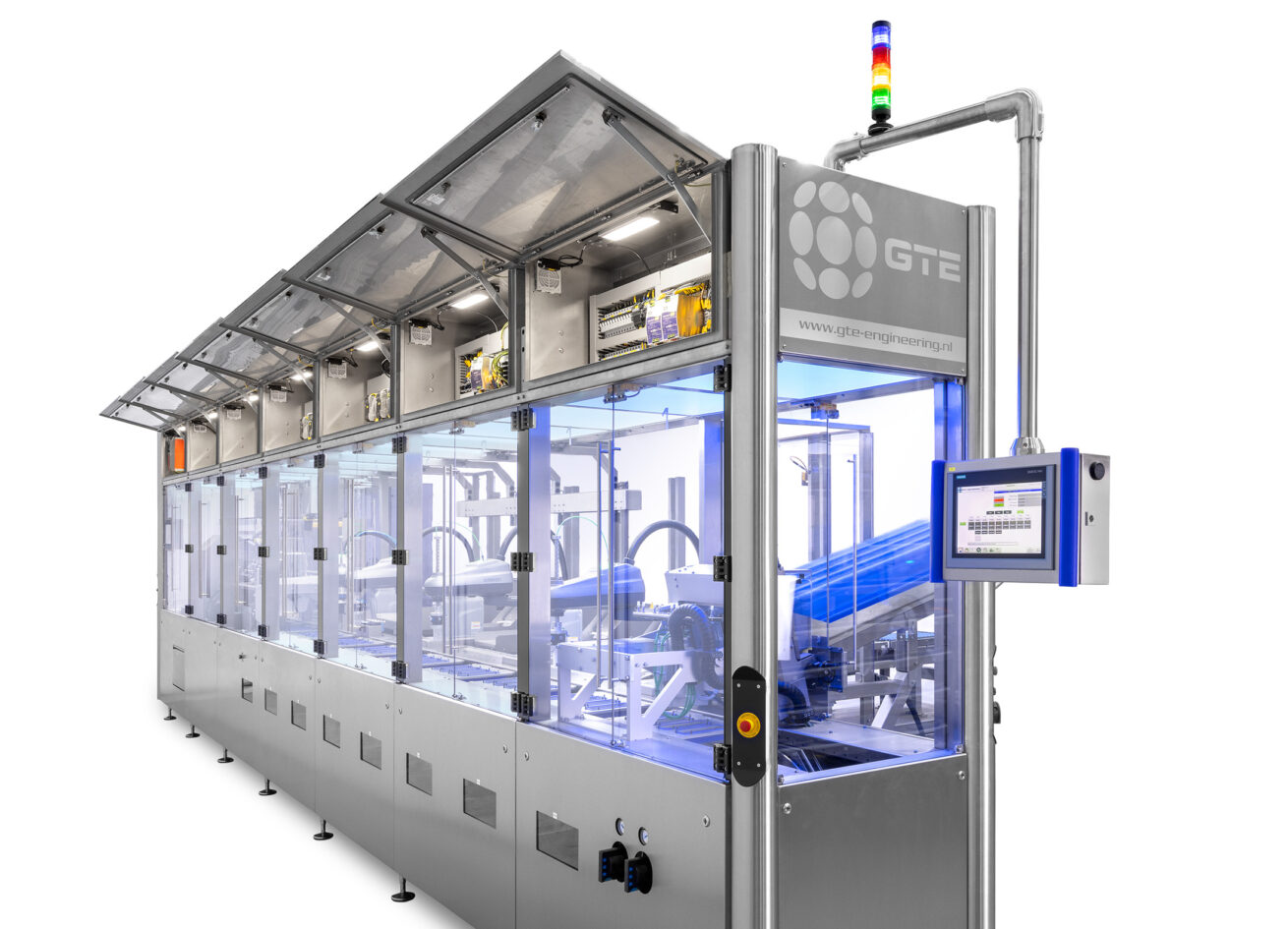

Modular concept

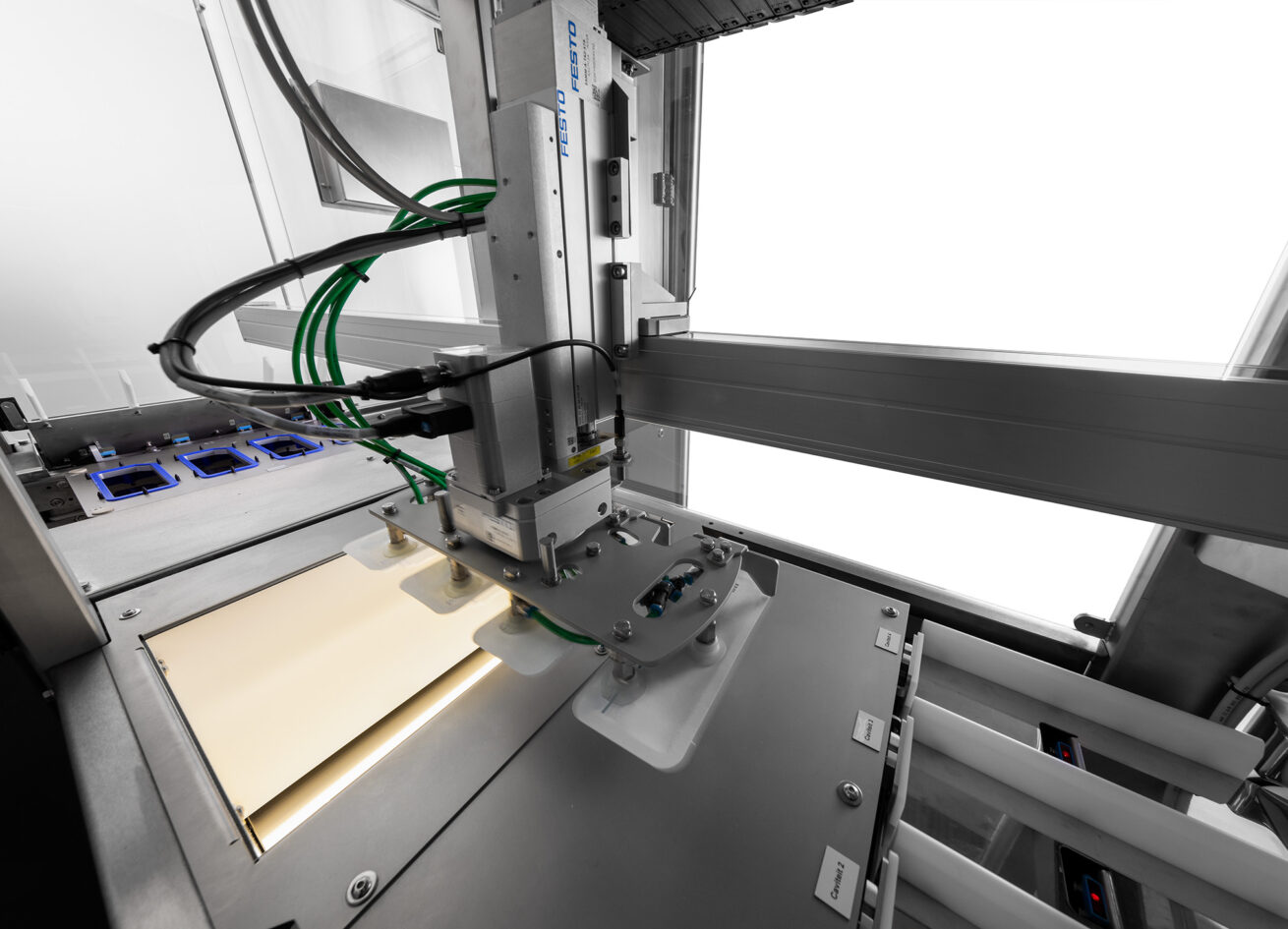

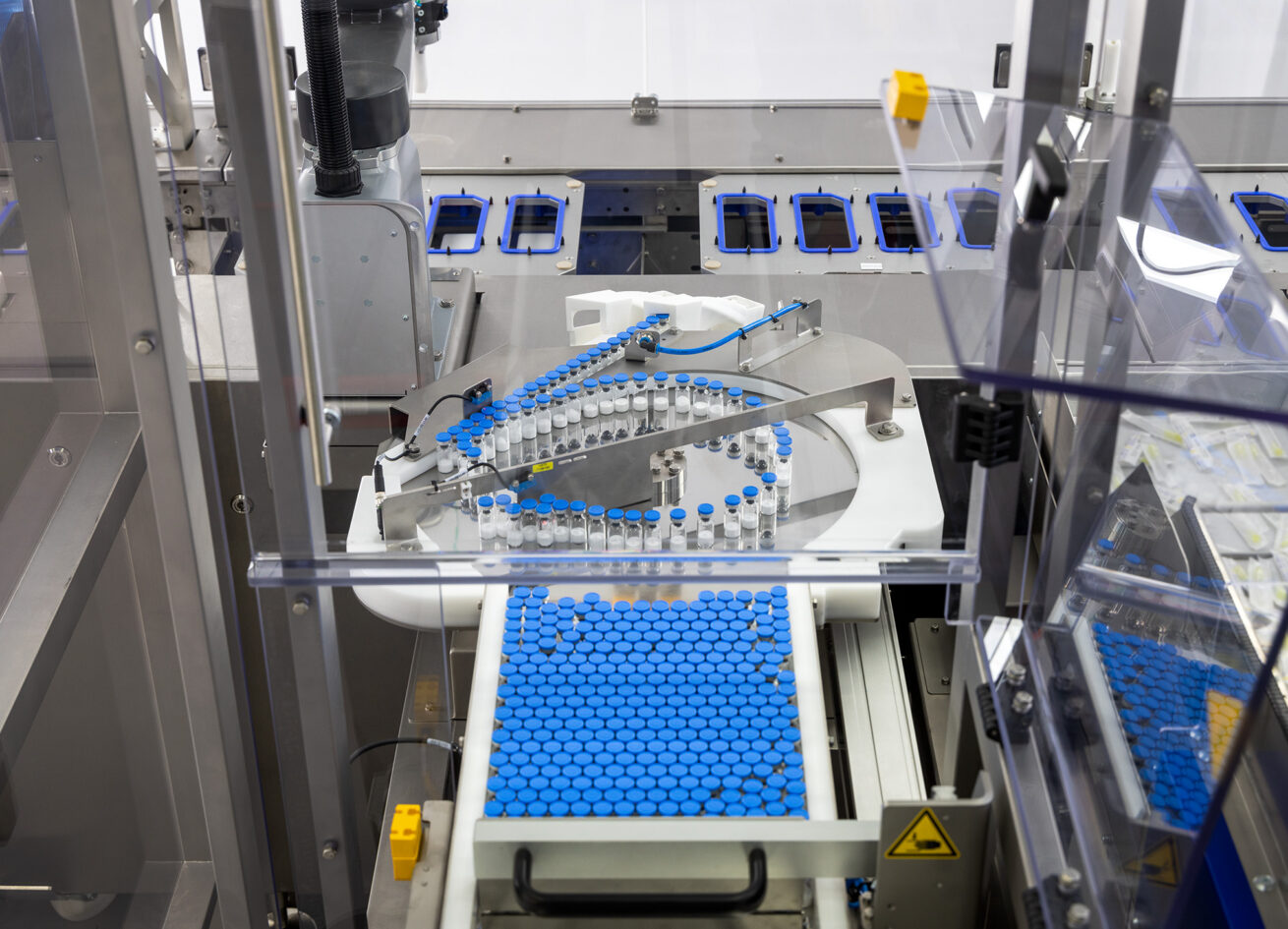

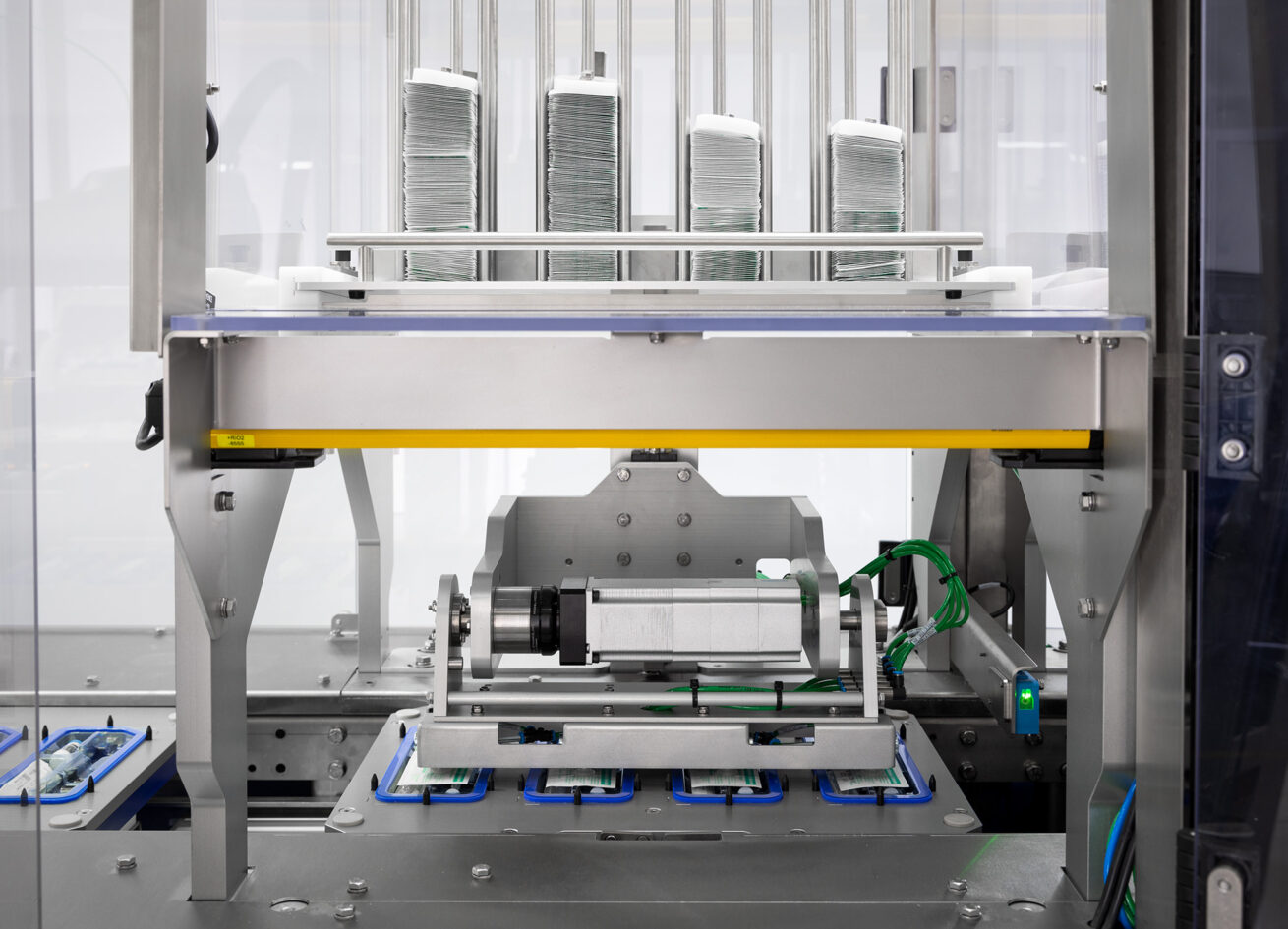

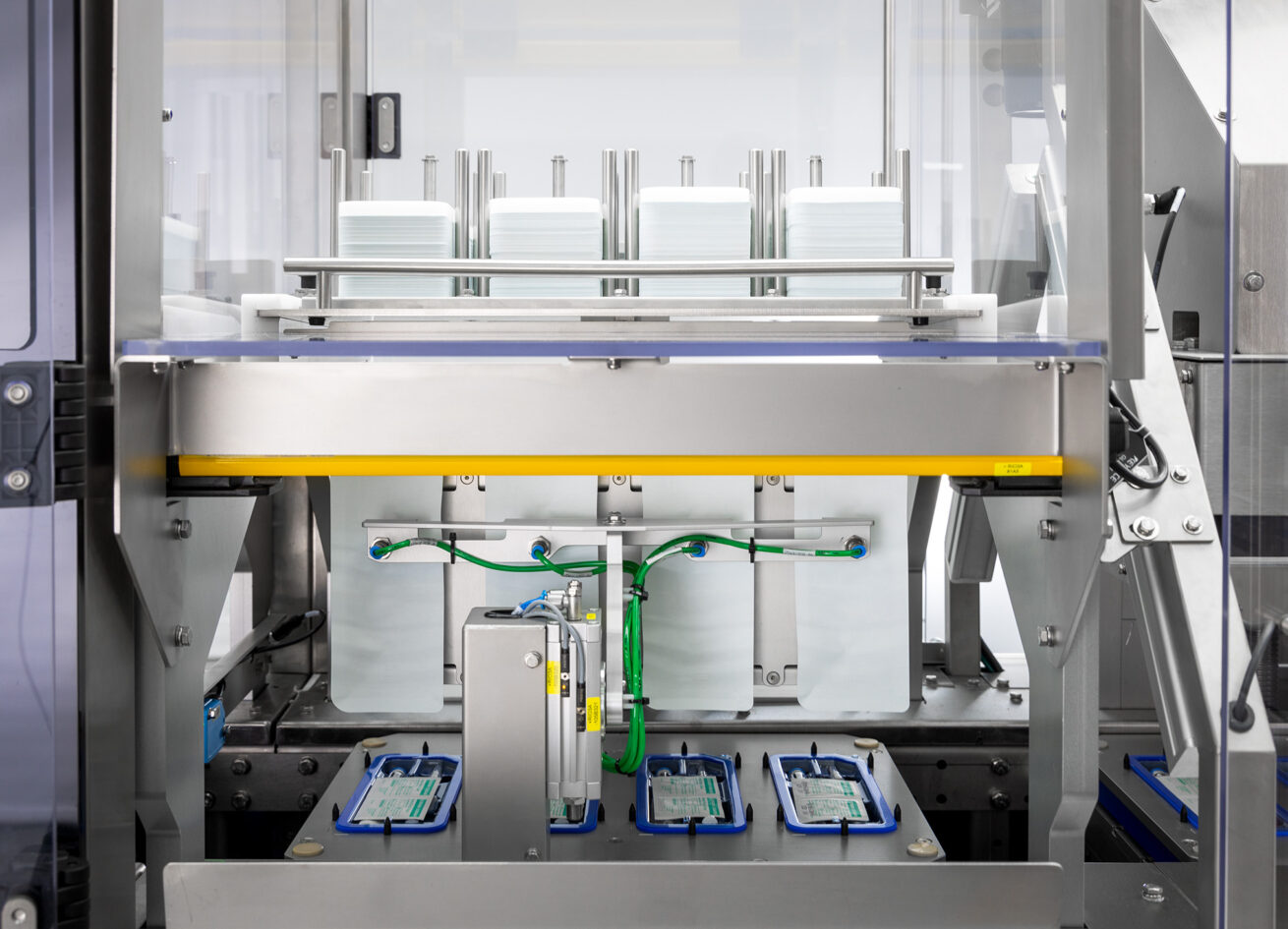

The linear blister filling and sealing machine is modular and equipped with docking stations. This keeps the machine easily accessible at all times for maintenance and line clearance.

Advantages of the blister fill and seal machine

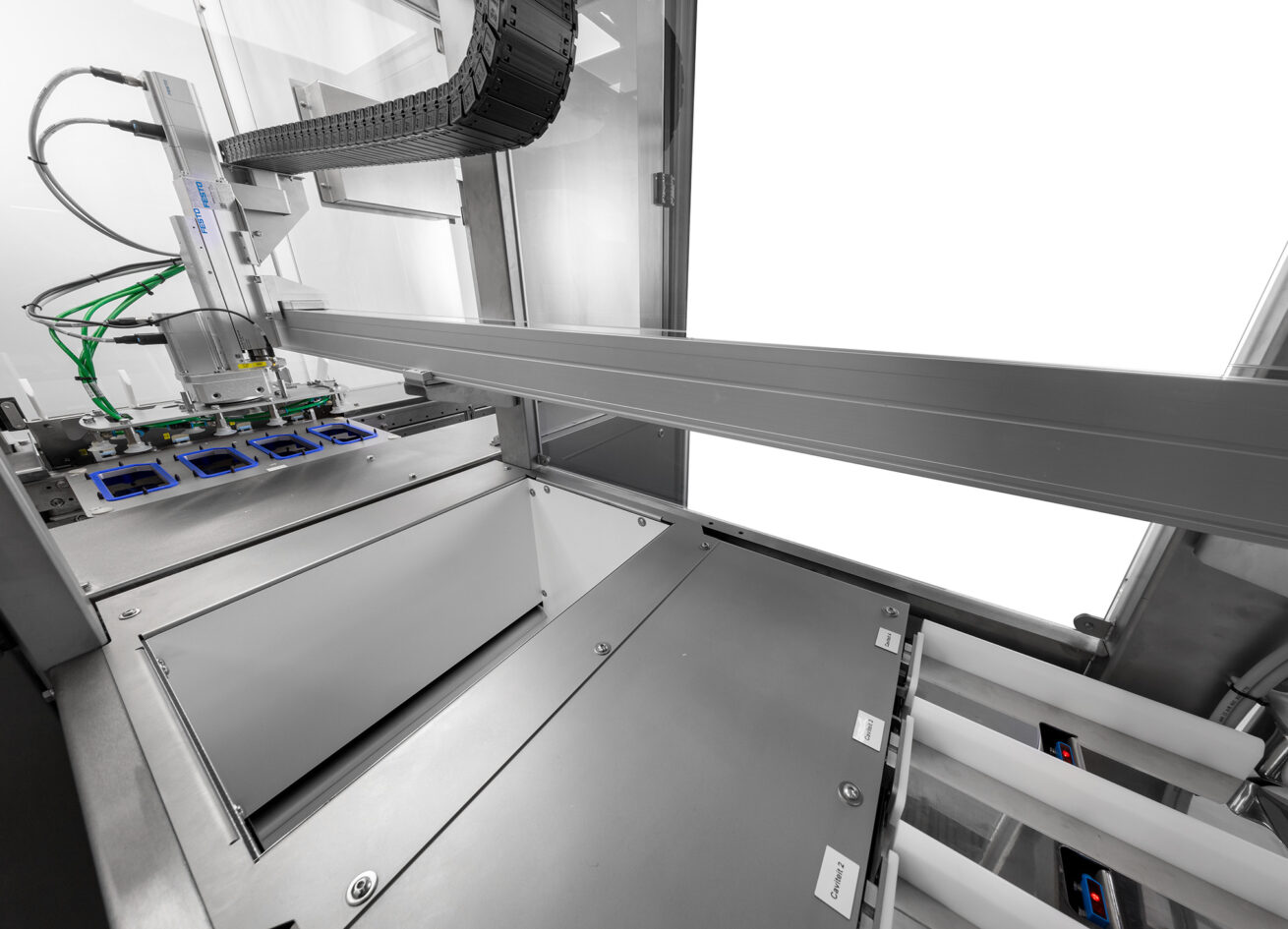

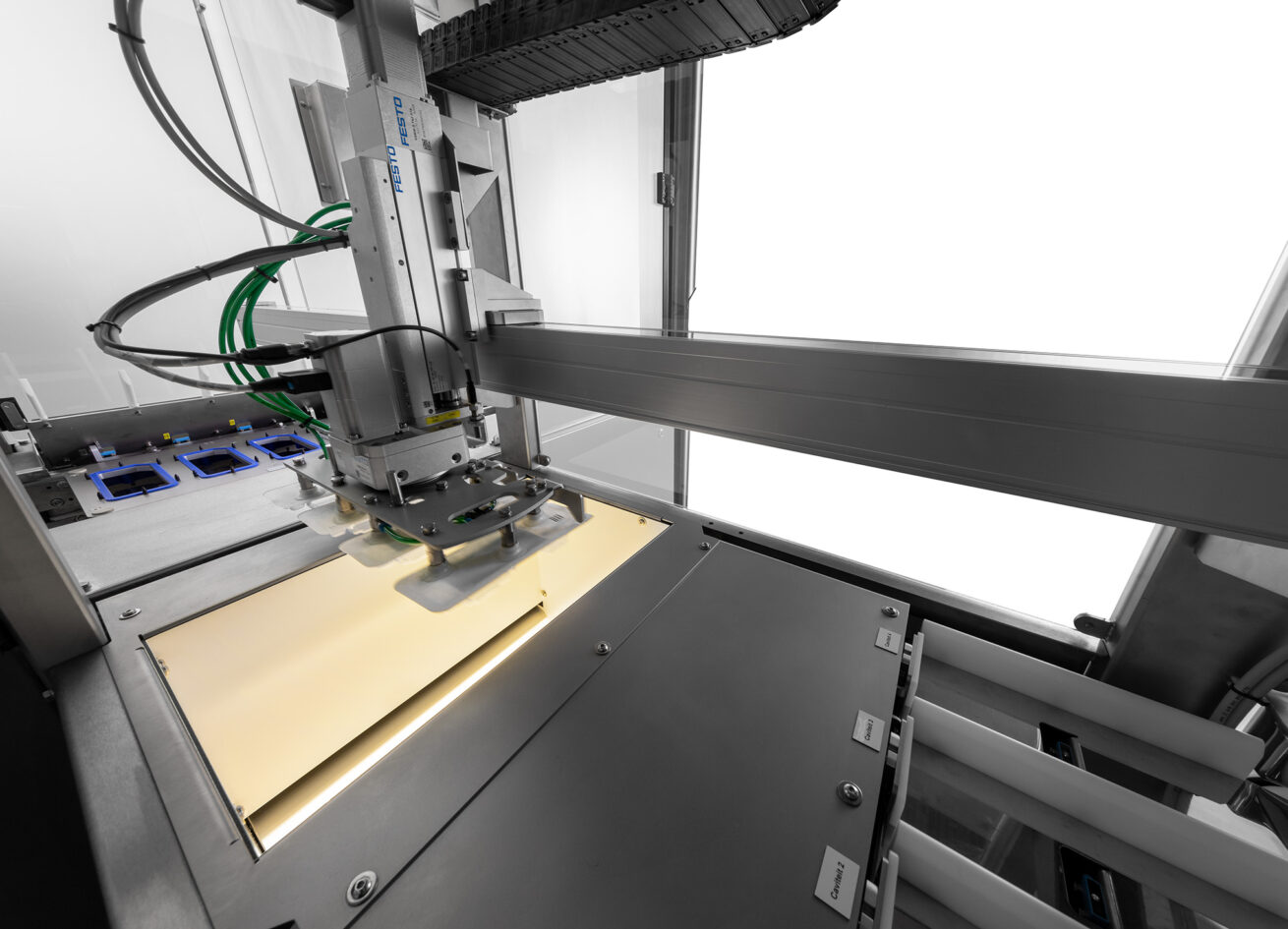

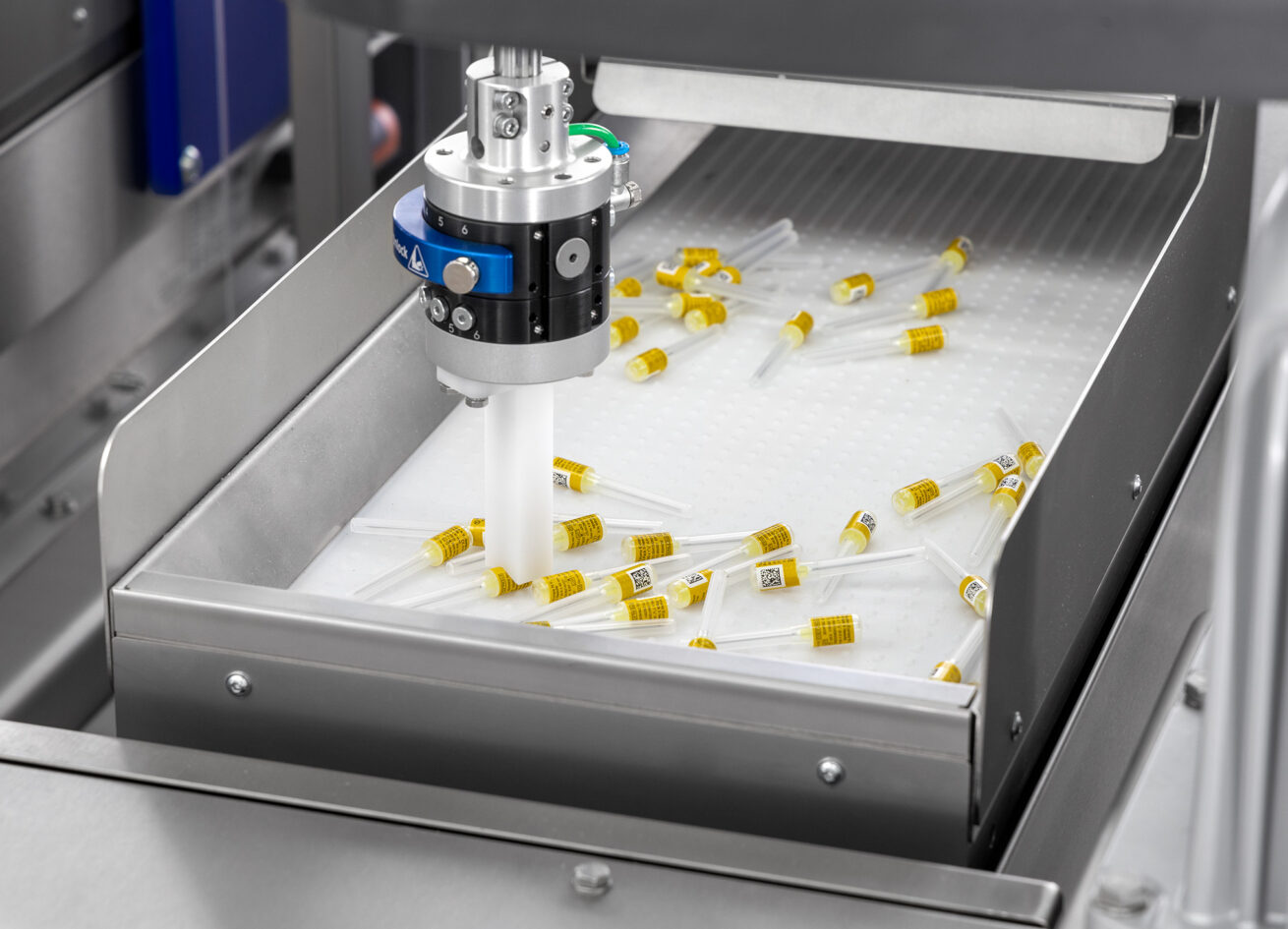

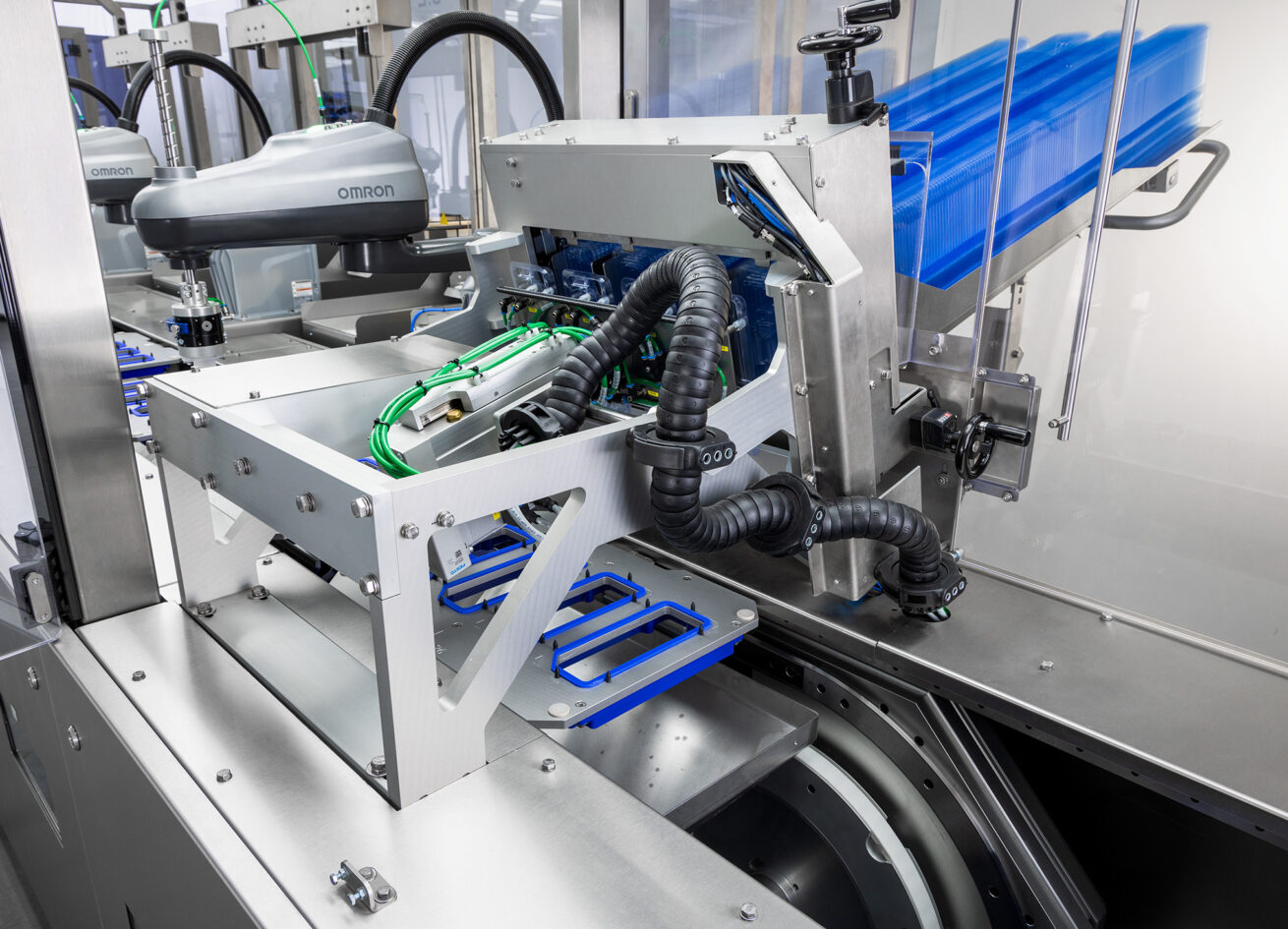

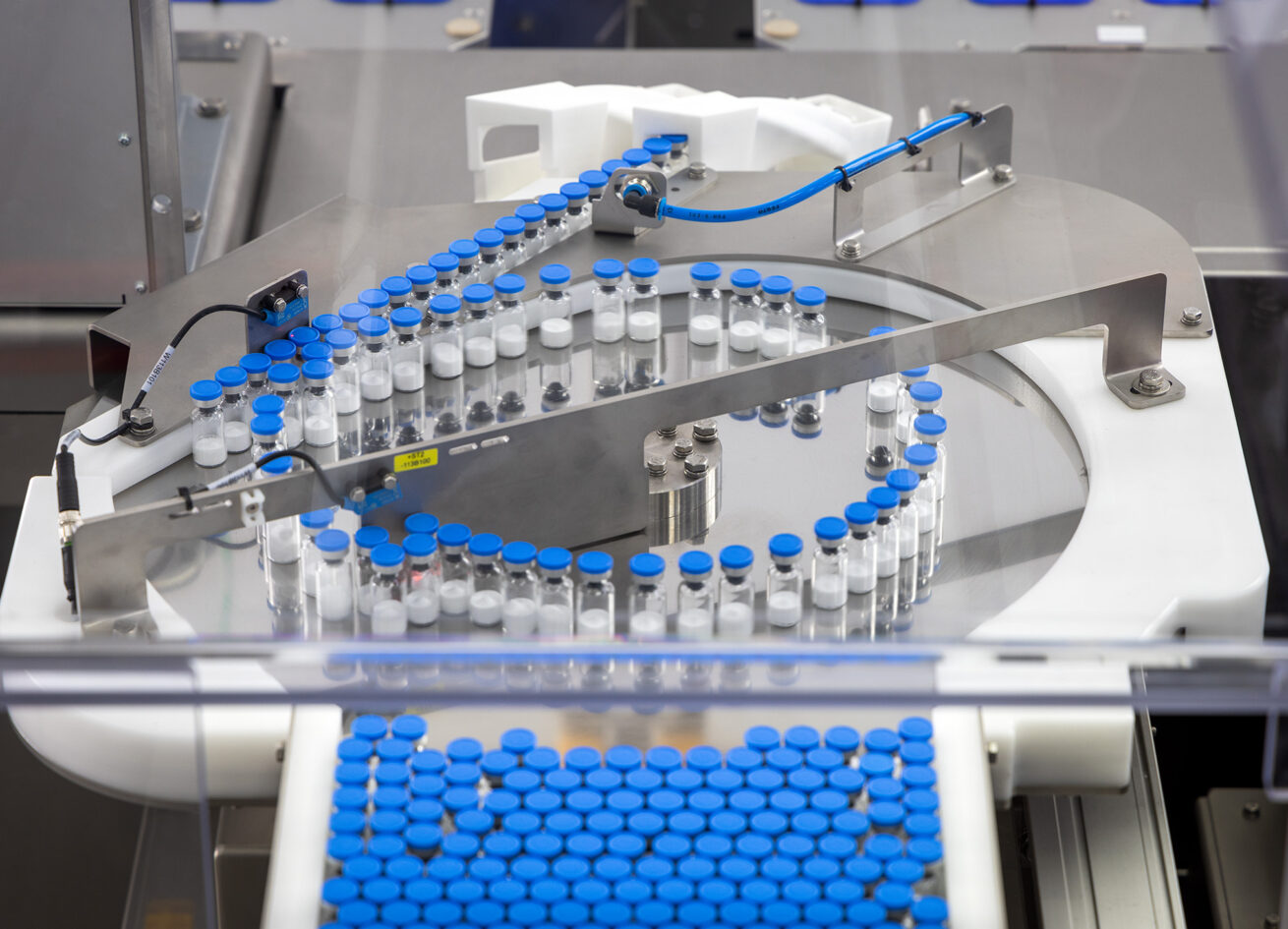

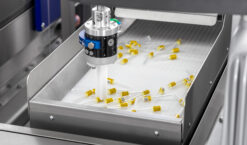

Feeding the needles and syringes is set up using the “Any Feeders” feeding system, with a camera and robot. The machine makes sure everything’s oriented correctly by vibrating. The camera then checks whether all products are lying correctly, after which a SCARA robot picks up the products and places them in the blister. Want to process a different product? Then simply choose another recipe on the control panel and change the robot’s gripper.

This blister filling and sealing machine is perfect for medium and high production quantities of 1,300 to 1,500 blisters per hour. It’s a fully automatic machine with Siemens controls.

Dimensions

8,4 x 0,9 x 2,5 metres. The machine can be lowered a bit for transport, allowing it to fit through a 2-metre high passage.

Specifications

- Modular design, don’t have to start from scratch

- Flexible, short change-over time

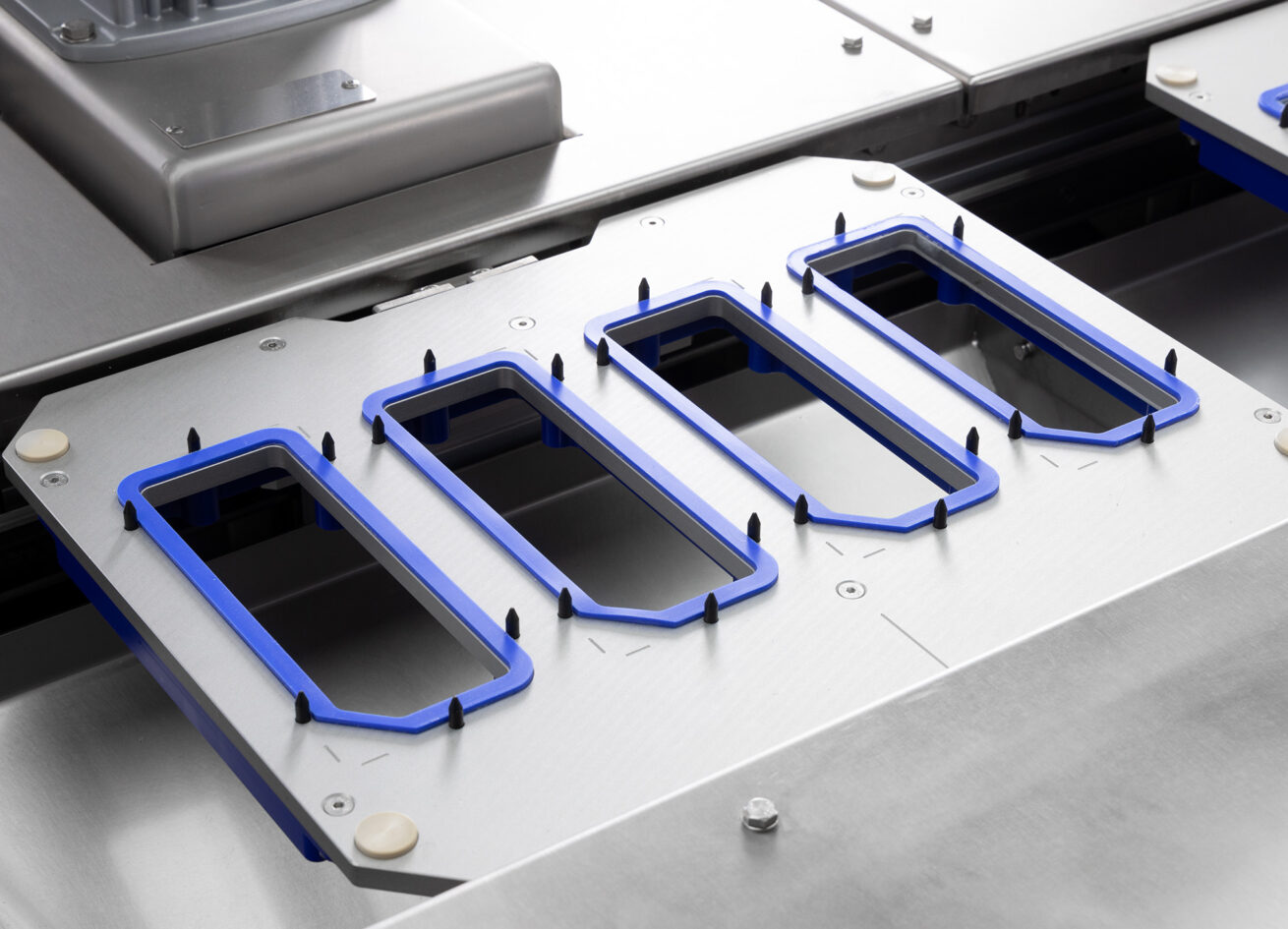

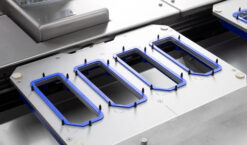

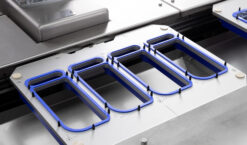

- Can handle different sizes of packaging

- Gripper is the only part that needs to be swapped out for a different product

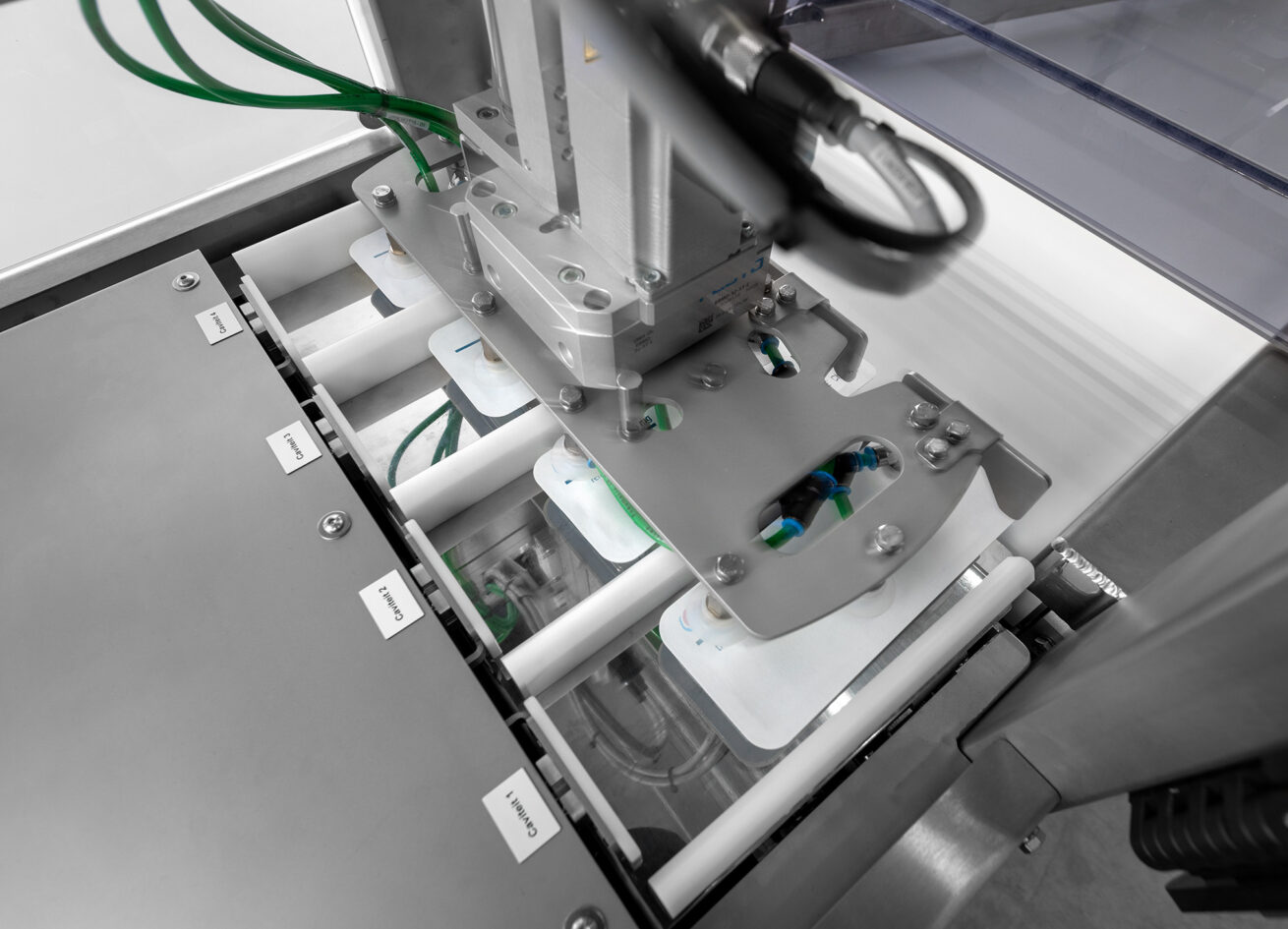

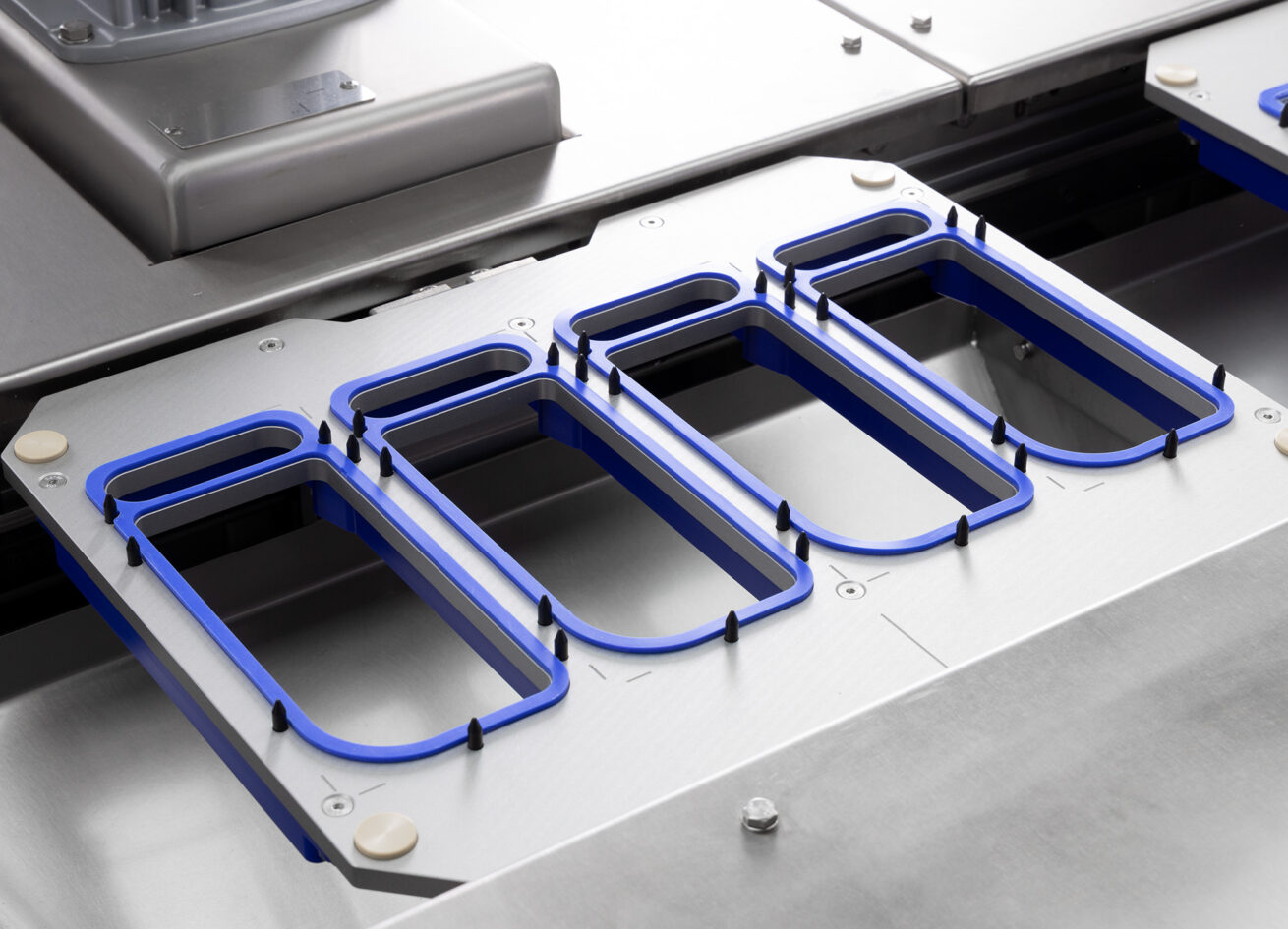

- The moulds, gripper, and sealing tool need to be changed for different blisters

- The machine is accessible because of docking stations

- Medium and high production quantities (1,300 – 1,500 blisters per hour)

- Electricity-based sealing

- Fully automatic filling and sealing

- Vision checks with Cognex camera

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)