The LAP-C Box folding machine

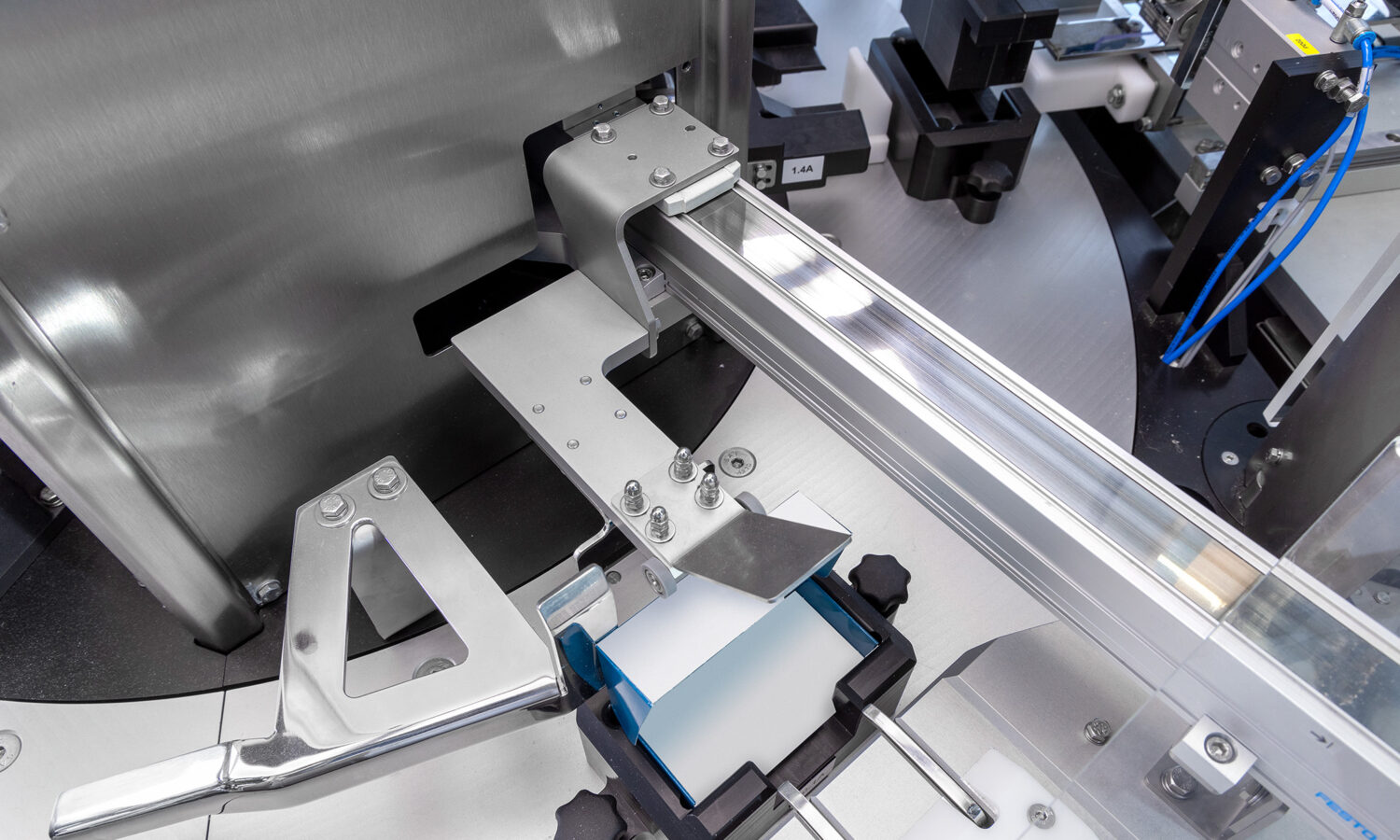

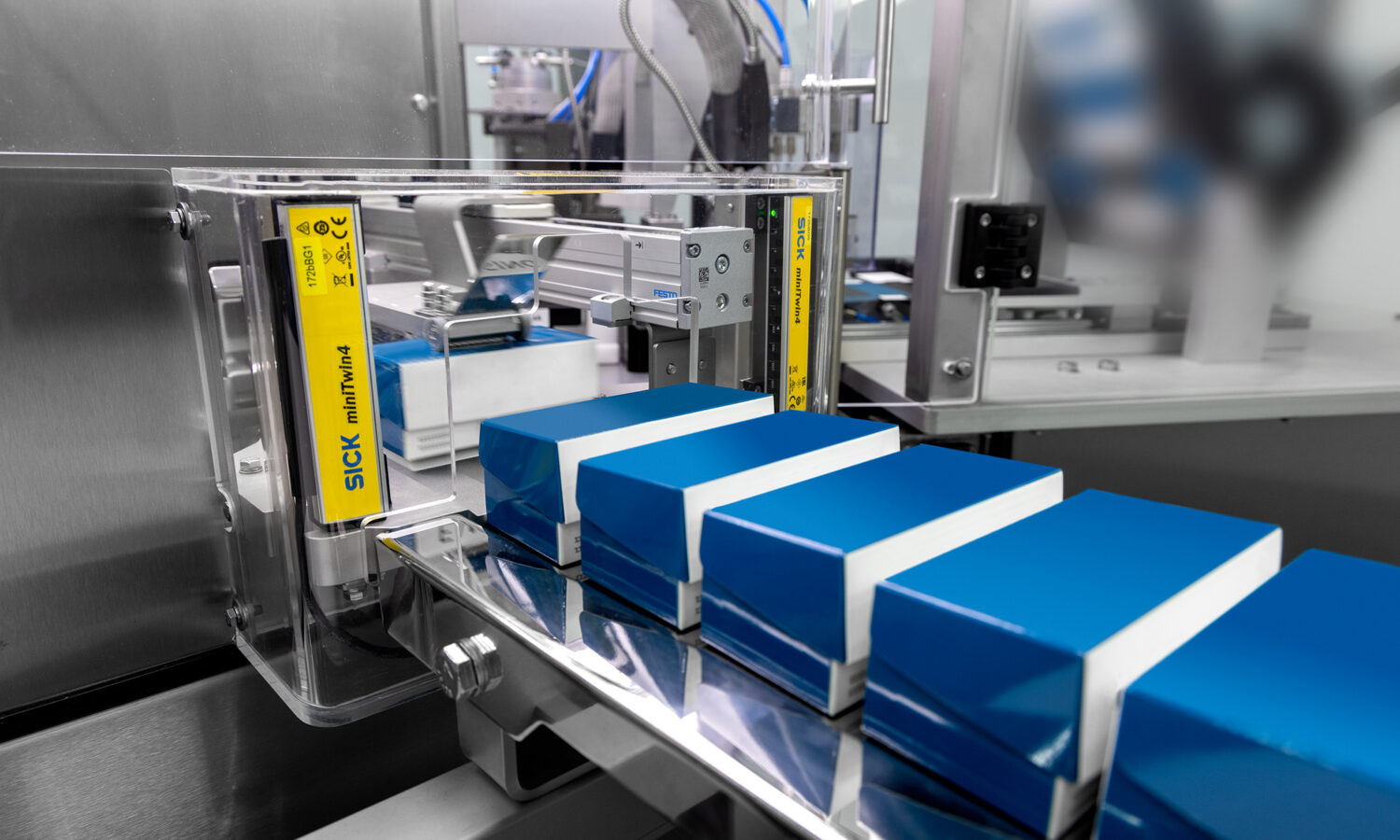

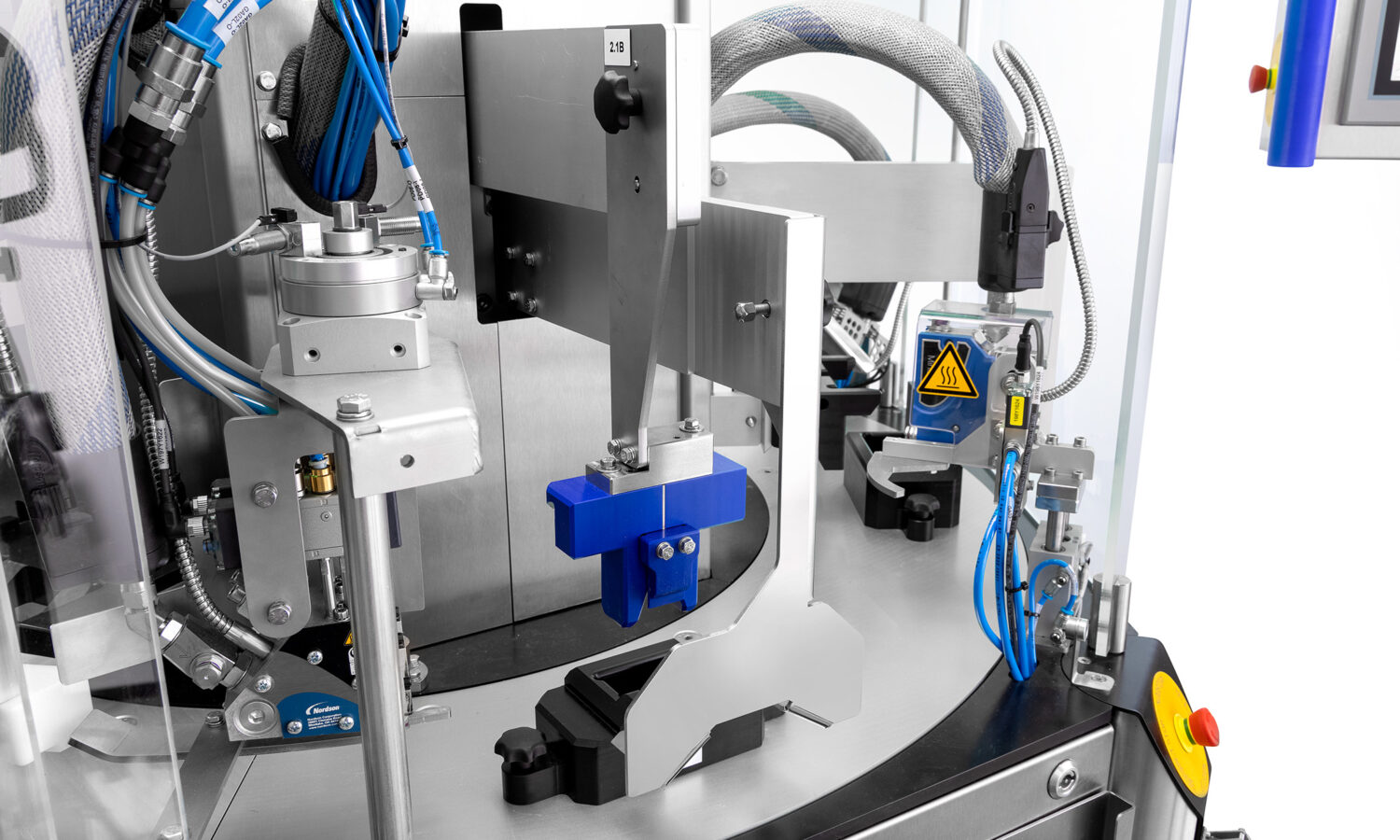

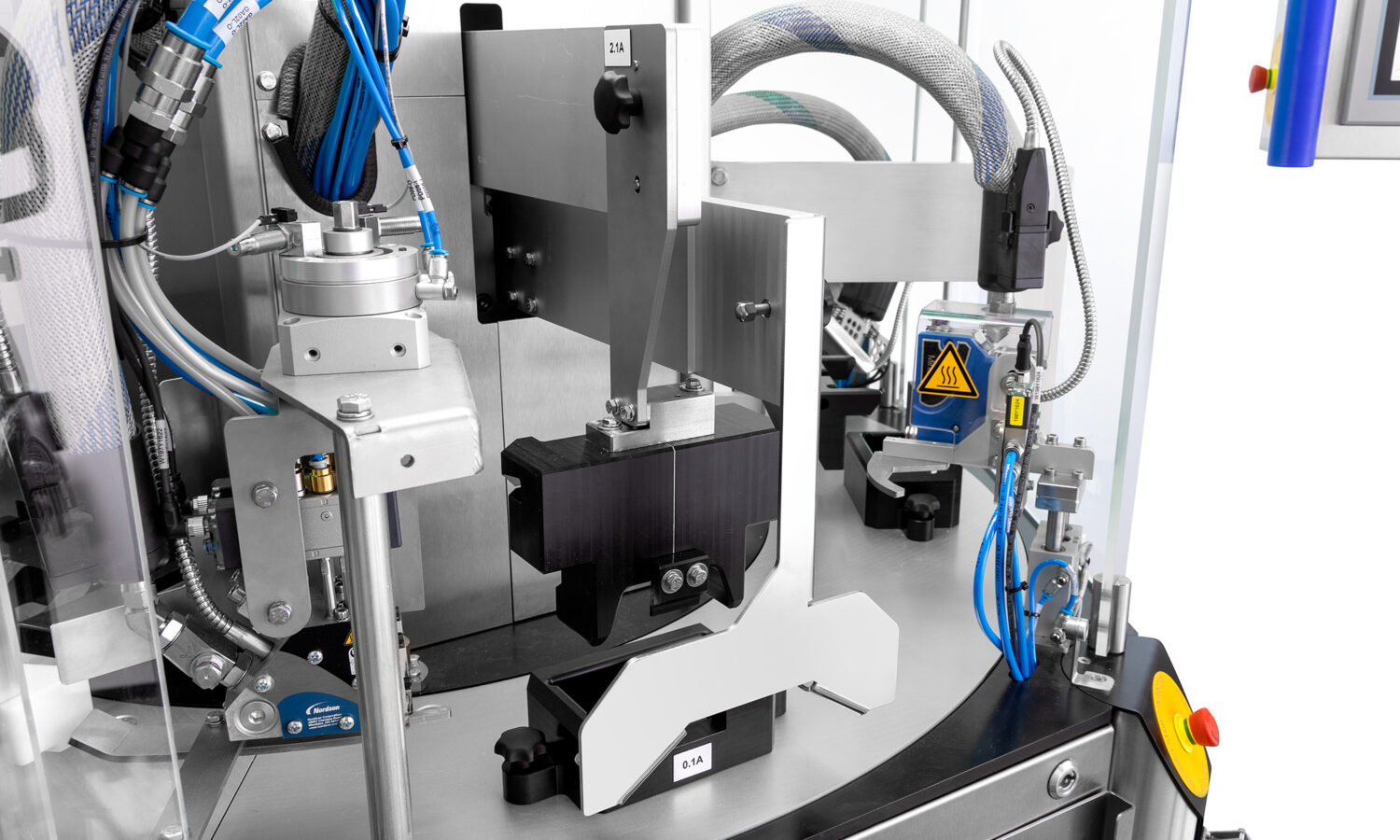

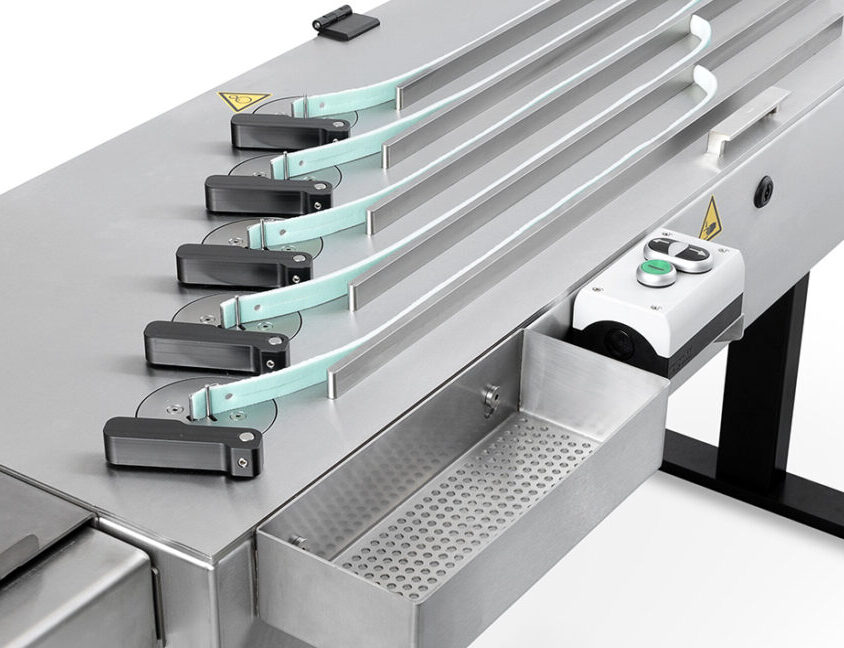

This LAP-C Box folding machine automatically separates the plano. It then applies some glue and folds the bottom of the box. Four stations fold the box and glue it shut with a hot-melt adhesive. The fifth station folds the insert and places it in the box. The sixth and final station closes the box and automatically transports it to a packing table.

The machine can handle two sizes of boxes with five different inlays. These boxes are of high quality and require a complex folding method.

The Solution? LAP-C

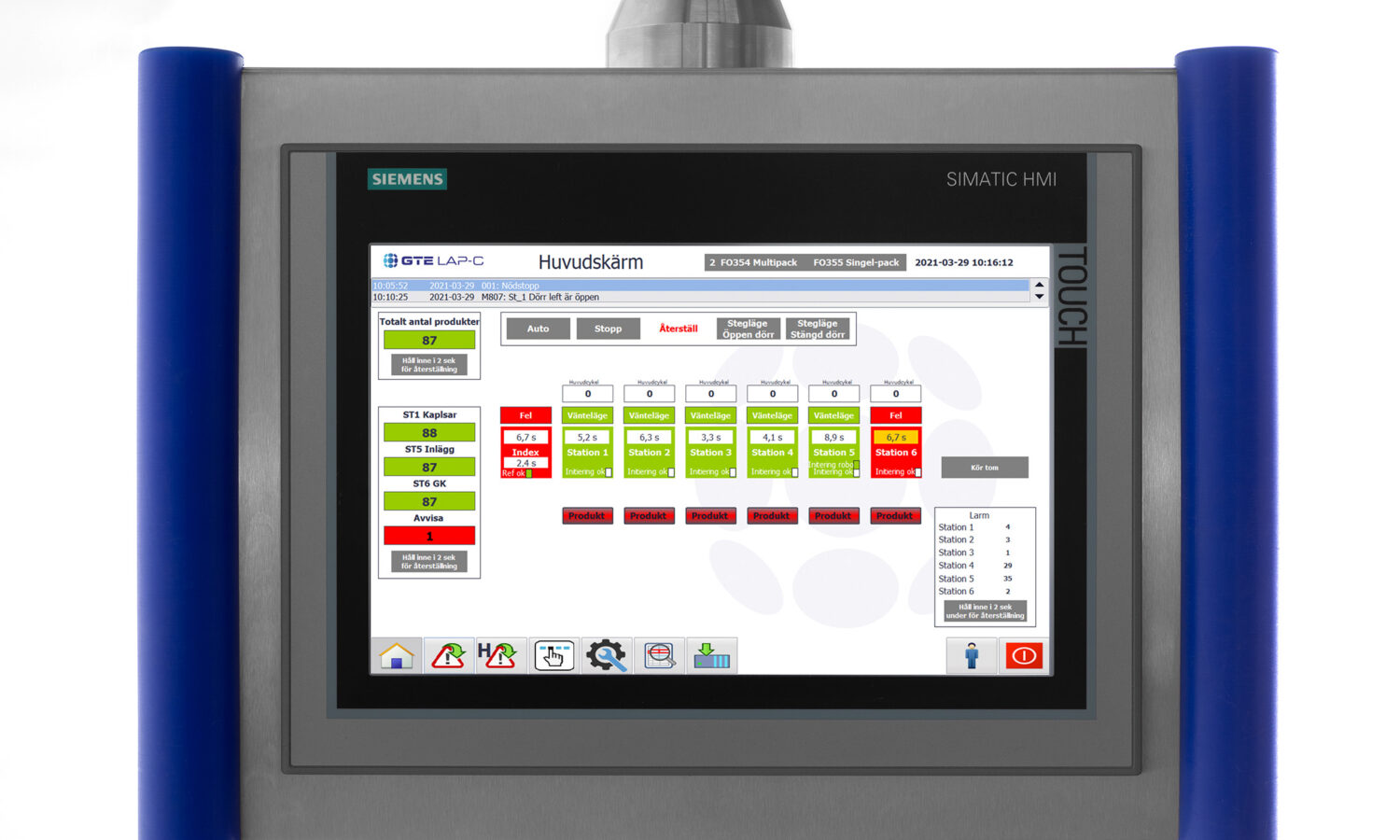

We can guarantee a machine with a small footprint when using the LAP-C as a base – extra important if you want to use the machine in a cleanroom. The machine can be quickly adapted to differently sized box thanks to the interchangeable parts, which can be swapped out without using tools. This machine has Siemens controls.

Specifications

- Based on our modular LAP-C Platform

- Can be combined with other standard or tailor-made machines

- Small footprint

- Efficient and cost-effective

- Fast ROI

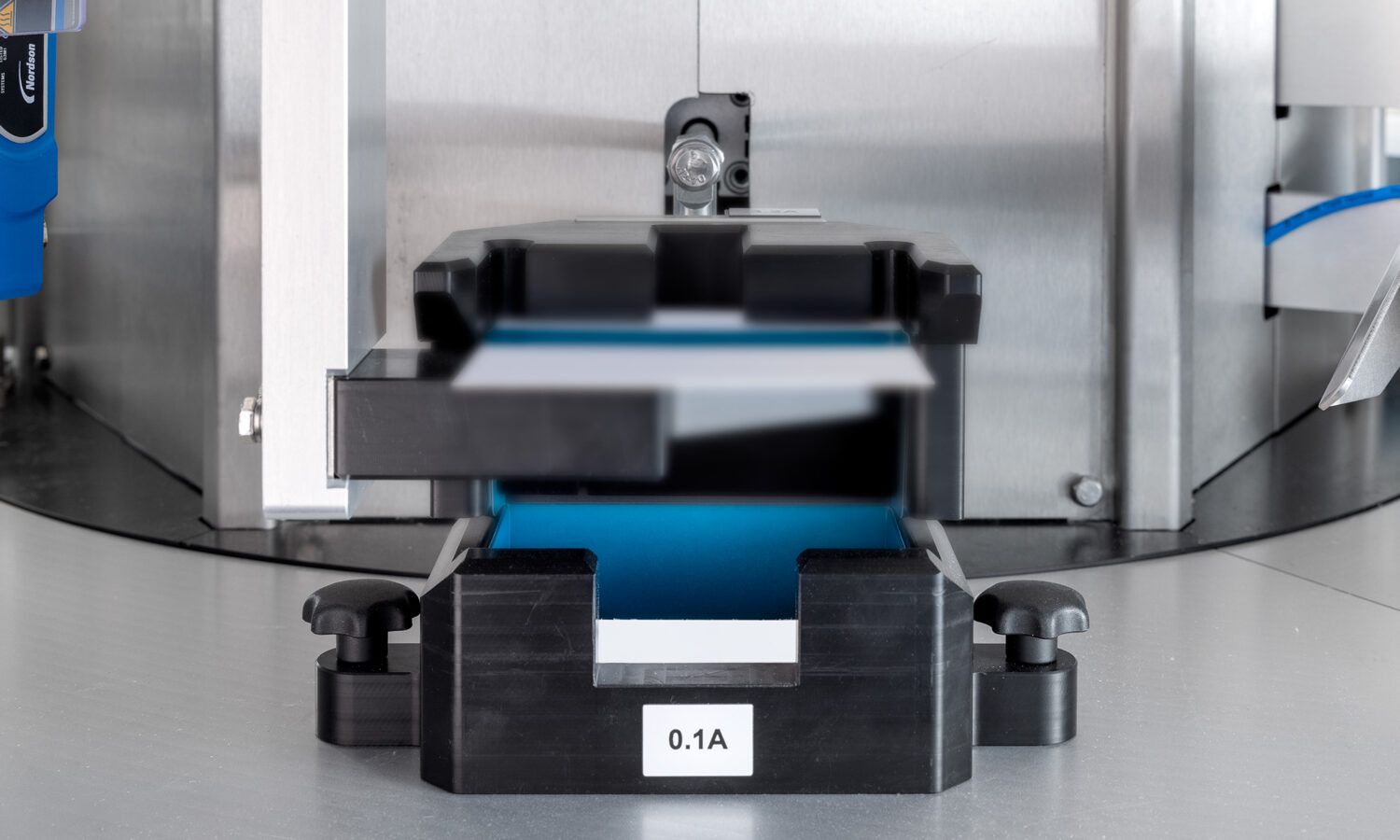

- Quick change-over by changing parts without tools

Requesting assets

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)