What is medical device assembly?

Medical device assembly refers to the process of putting together components of medical products, such as syringes, plungers or catheters, under controlled and validated conditions. Because these products are used directly in healthcare, every step must meet strict regulatory and quality requirements.

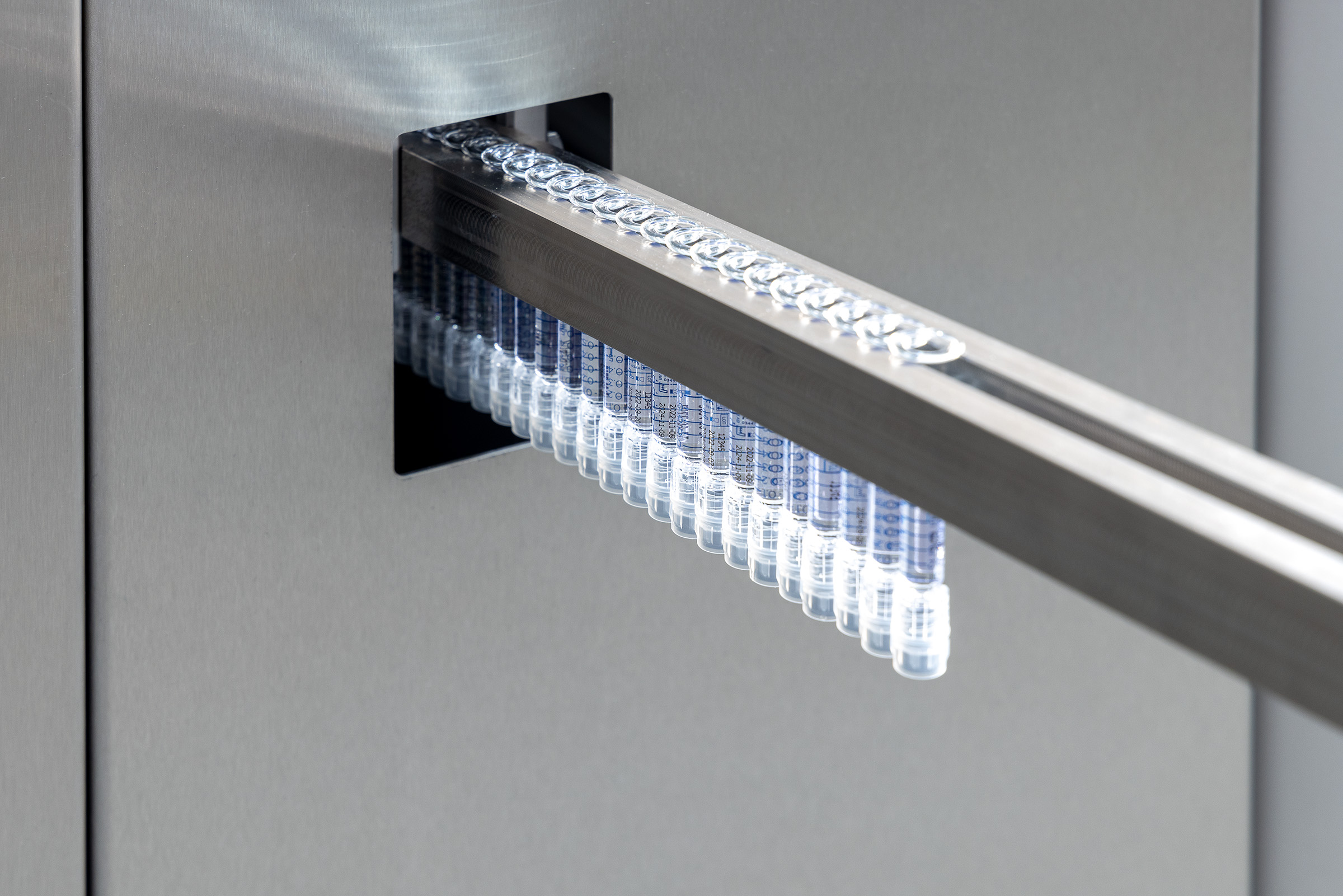

Modern medical device assembly machines combine robotics, feeding systems, vision inspection and control software to ensure every component is positioned, joined and sealed perfectly.

Common technologies include:

- Flexible feeding systems like Flexibowls, guided by cameras to handle different parts accurately.

- Vision checks and seal checks for validation and traceability.

- Automated glueing or welding for tight, sterile connections.

At GTE, our systems are designed for high-mix, low-volume production, making them ideal for manufacturers running small or medium batches, or multiple product types. With flexible recipes and quick changeovers, a platform can easily switch between product variants while maintaining consistent process validation.

The impact of medical device assembly

The impact of medical device assembly automation on healthcare manufacturing is significant. Many assembly tasks in the industry are still performed manually, increasing the risk of contamination and inconsistency. Automated systems minimise these risks and deliver several clear advantages:

- Improved patient safety through repeatable, validated processes.

- Consistent product quality, regardless of operator skill or shift.

- Higher output and efficiency, even for small-batch production.

- Reduced labour dependency, addressing operator shortages.

- Lower long-term costs, with a clear ROI over time.

For companies developing new medical devices, automation also helps during clinical trials. Starting with a validated small-batch process allows you to scale up later without changing the production method, saving both time and validation effort.

Learn how other manufacturers improved quality and flexibility through GTE solutions in our success stories.

Why choose GTE Engineering for your medical packaging equipment?

Industry expertise

With years of experience in the medical and pharmaceutical sectors, we understand the specific challenges of compliance, precision, and sterility.

Custom and standard solutions

We offer flexible options, from ready-to-use machines to fully customized systems tailored to your requirements.

Trusted quality

Our machines are used by medical and pharmaceutical companies worldwide, delivering consistent performance and long-term reliability.

Advanced automation

Featuring the latest in packaging technology, our machines are designed to streamline operations and reduce manual handling.

Custom-made solutions for the medical industry

Every product has unique requirements; and so should your medical device assembly machine. At GTE Engineering, we design and build custom solutions that match your exact process and compliance needs.

From semi-automated systems, where operators insert parts manually, to fully automated platforms with complete robotic handling, we create machines that fit your production environment and budget. Our engineers develop each system according to your user requirement specifications and ensure compliance with ISO 13485 and EU MDR 2017/745.

We use high-quality, off-the-shelf components for long-term reliability and easy maintenance. Each solution is thoroughly tested, validated and documented, ensuring smooth integration into your manufacturing process.

Contact us today

Ready to elevate your medical packaging process? Contact us to discuss your automation goals and find out how GTE Engineering can help you achieve expert precision in medical device assembly.

Together, we’ll develop packaging solutions that meet your production goals while maintaining precision and compliance.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields