Our Approach

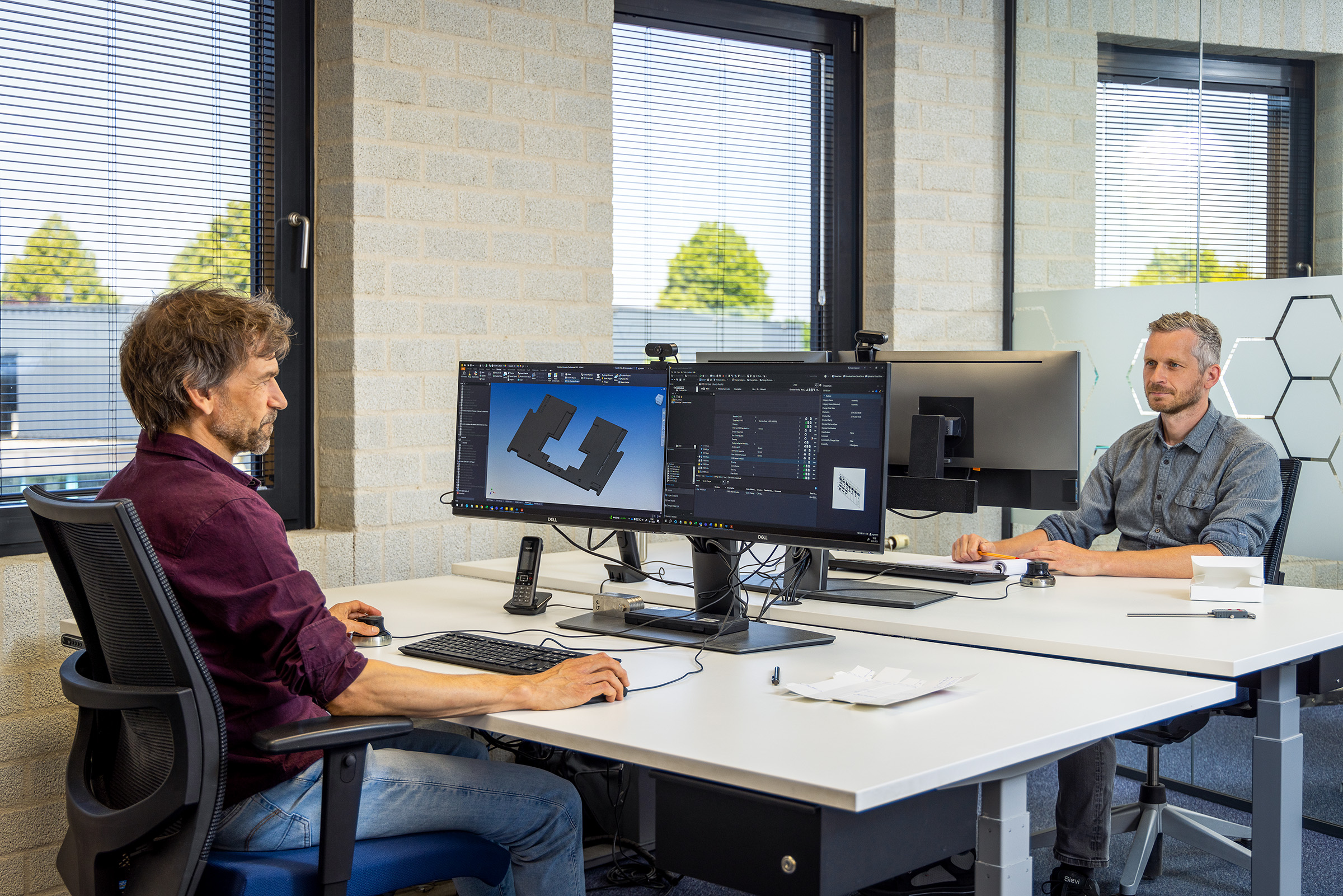

Your requirements and wishes are our priority. Whether you’re looking for a custom-made machine used for one specific purpose or one of our Platforms used for various products, we will work together to assess what you need and how we can best integrate it into a machine.

Your Wish is Our Command

We develop machines based on User Requirement Specification (URS) set by you. We both look at what the machine must do and what could be nice to add. We won't sell you a high-end machine if you only need an entry-level model.

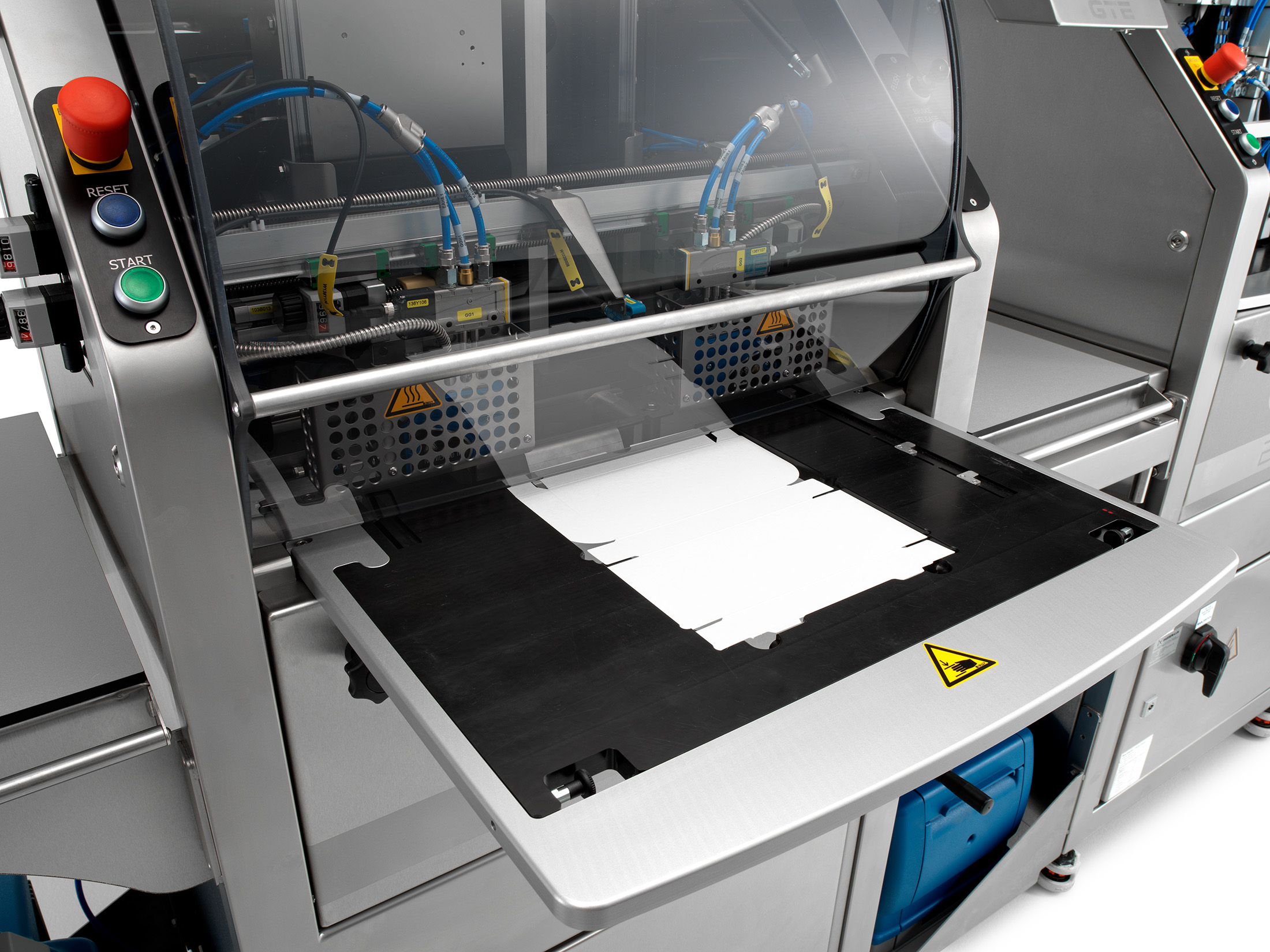

Manufacturing Your Machine

When your machine is in production, we constantly test and continue fine-tuning, so you can be sure that no unnecessary errors and problems occur when you have the machine in use. That's one of the reasons we can guarantee the quality of our machines.

Delivery

When delivering your machine, we install it carefully and give operators and technicians the necessary training so they know all the ins and outs of the machine. As a result, any problems that arise can be solved by your own staff, minimising downtime as much as possible.

Service and Maintenance

Any problems that arise can usually be resolved by your own technicians. If not, we are here to help. Problems can usually be resolved remotely – the machines are not down for long, and the production process can be restarted quickly.

Quality Standards

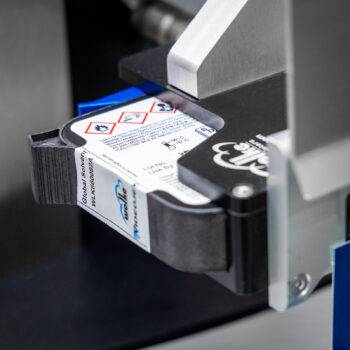

In the medical and pharmaceutical sector, validation is a crucial step when commissioning a new machine into use. Therefore, we ensure the machine works as it should and complies with all quality standards at the time of validation, avoiding delays and making the process as efficient as possible.

High-Quality Components

GTE only uses high-quality components in the development of its machines. These components are off-the-shelf products from reputable suppliers. This allows us to guarantee that the quality of the parts is of the highest level.

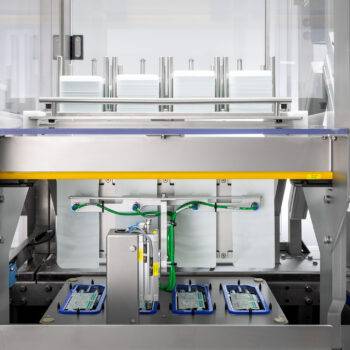

The advantage of GTE Engineering’s machines is that you can quickly switch production processes. The interchangeable parts in the machines, such as blister moulds, are easily and changed without the need of tools, allowing you to restart the production process in no time!

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

GTE Platforms

Our GTE Platforms have been developed for total solutions. From semi-automated to fully automated processes, it’s all possible with our GTE Platforms. Thanks to our platform’s modularity, you can easily expand your semi-automated process later without having to re-validate the entire process: only the new part needs to be validated. This keeps the automation expansion efficient, while you lose as little production time as possible.

GTE Custom-Made

GTE Custom-Made is for companies looking for a non-existent machine to meet specific requirements. One of the GTE Custom-Made success stories is the Semi-automatic assembly machine Eye Drop device. This machine was designed after a clinical trial where we developed manual tools for the customer. After the clinical trial, the customer wanted a semi-automated machine for the same process.

Discover our knowledge & inspiration

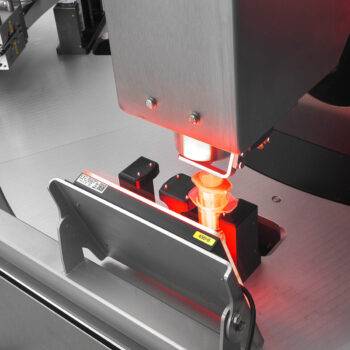

Whitepaper: Everything about vision systems in the pharmaceutical and medical industry

Precision and accuracy are extremely important. Whether they are used for correctly labeling products, or verifying the integrity of packaging, vision systems play a crucial role in any production process. What are their strengths and limitations, how do you prepare for their implementation, and what will the future look like in terms of, for example, AI? We are happy to help you get started; download the free whitepaper!

The Importance of IQ, PQ, and OQ in Machine Construction for the Pharmaceutical and Medical Industry

In the pharmaceutical and medical industries, developing machines that meet the highest quality and regulatory standards is essential. Therefore, the steps of IQ (Installation Qualification), PQ (Performance Qualification), and OQ (Operational Qualification) are followed during the construction of these machines. These qualification tests ensure that machines meet the required standards for installation, operation, and performance, and they are a critical part of the validation process.

At GTE Engineering, we use a traceability matrix and provide support with FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) protocols to make the validation process structured and efficient. This approach guarantees that all requirements are documented and that the machines meet the highest standards in the pharmaceutical and medical industries.

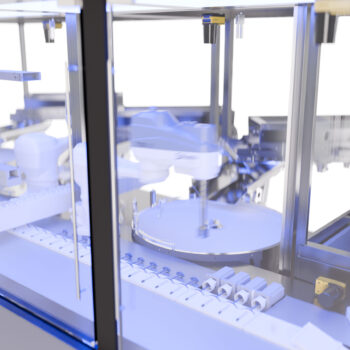

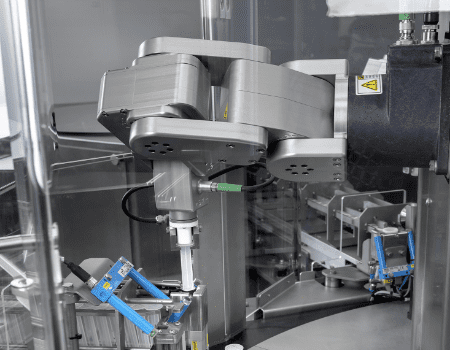

The LAP-C with Mecademic robot

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

What is ‘Smart Customization’?

ETO, CTO and Smart Customization. Terms that are more often used in mechanical engineering. But what do these terms mean? Everyone working in mechanical engineering should know what development these words describe.

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)