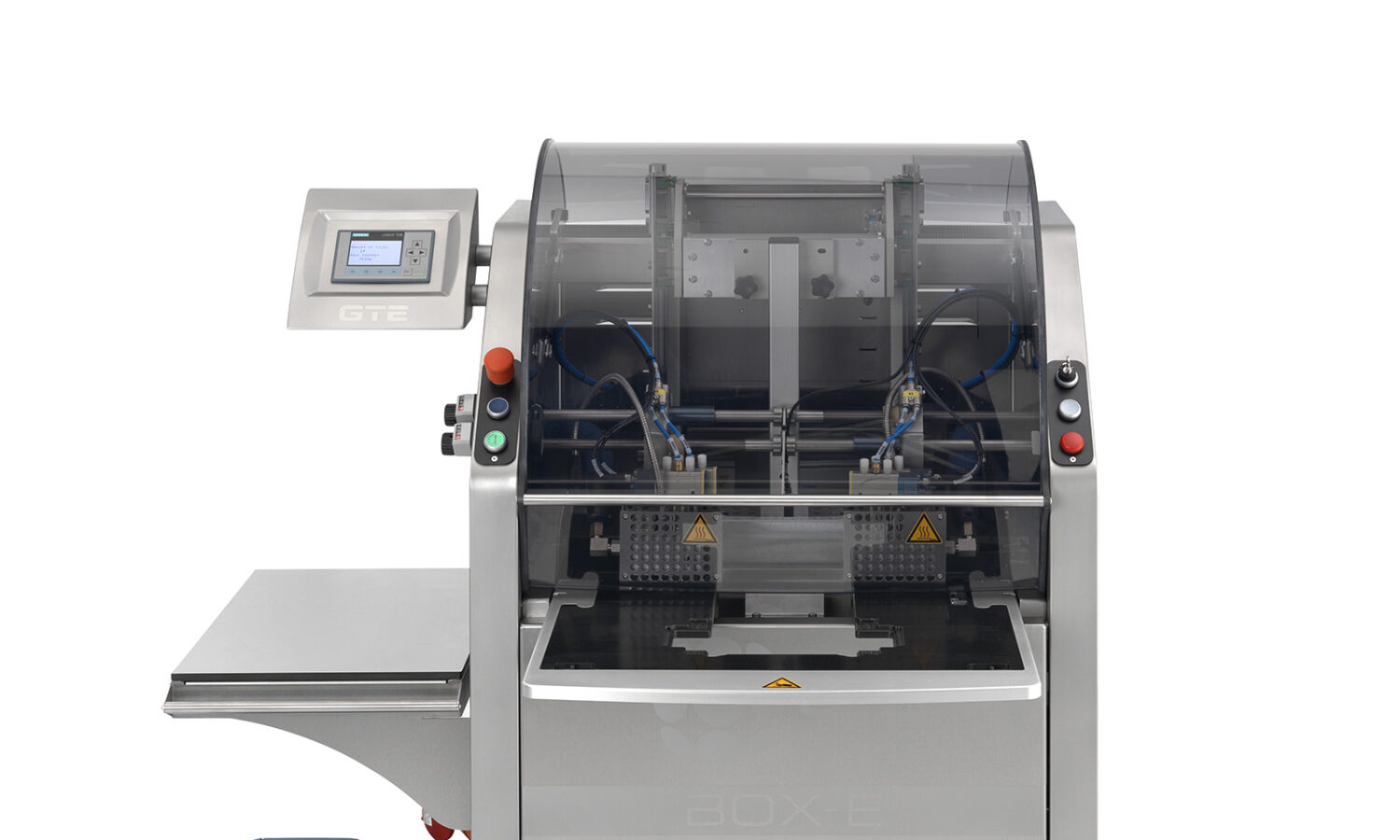

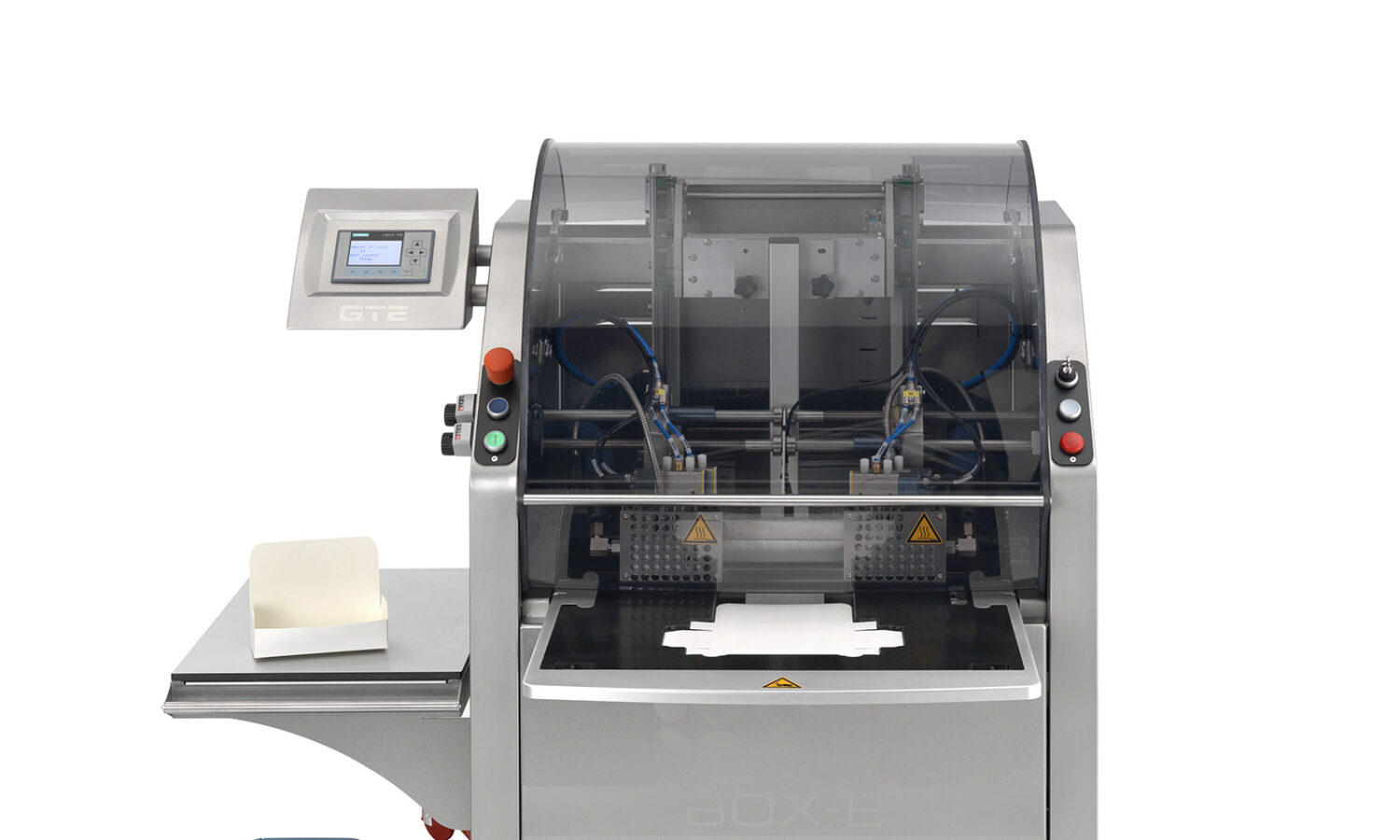

How does the BOX-E work?

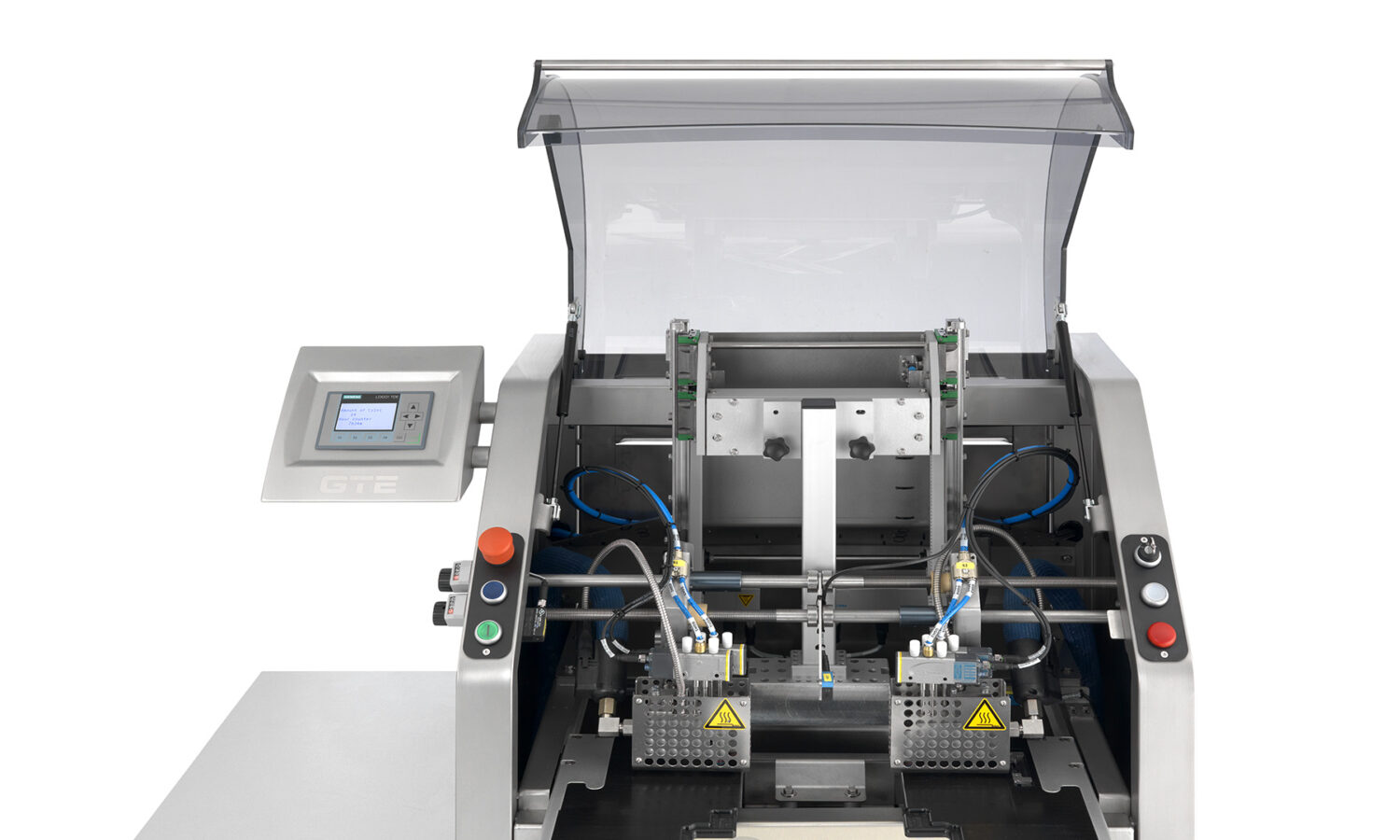

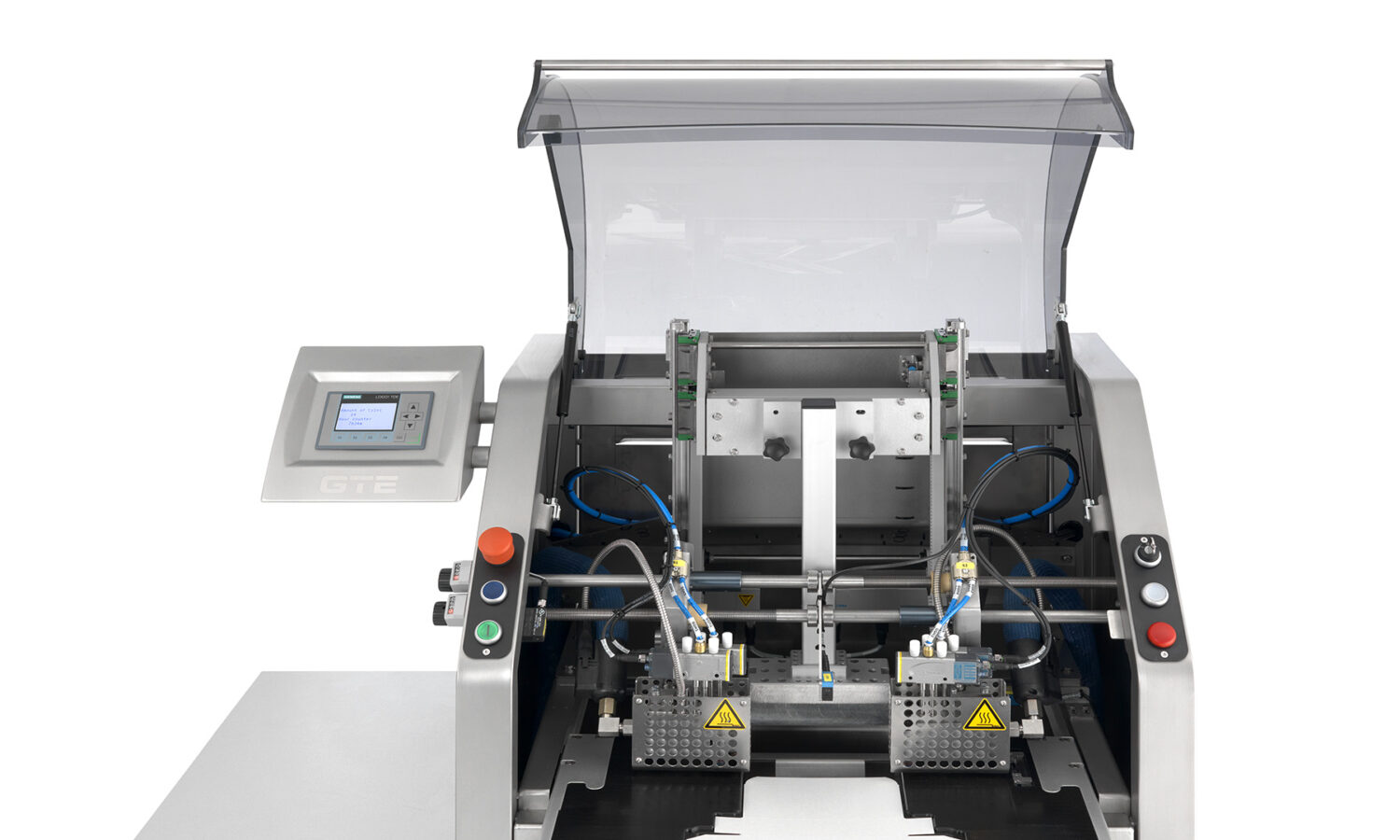

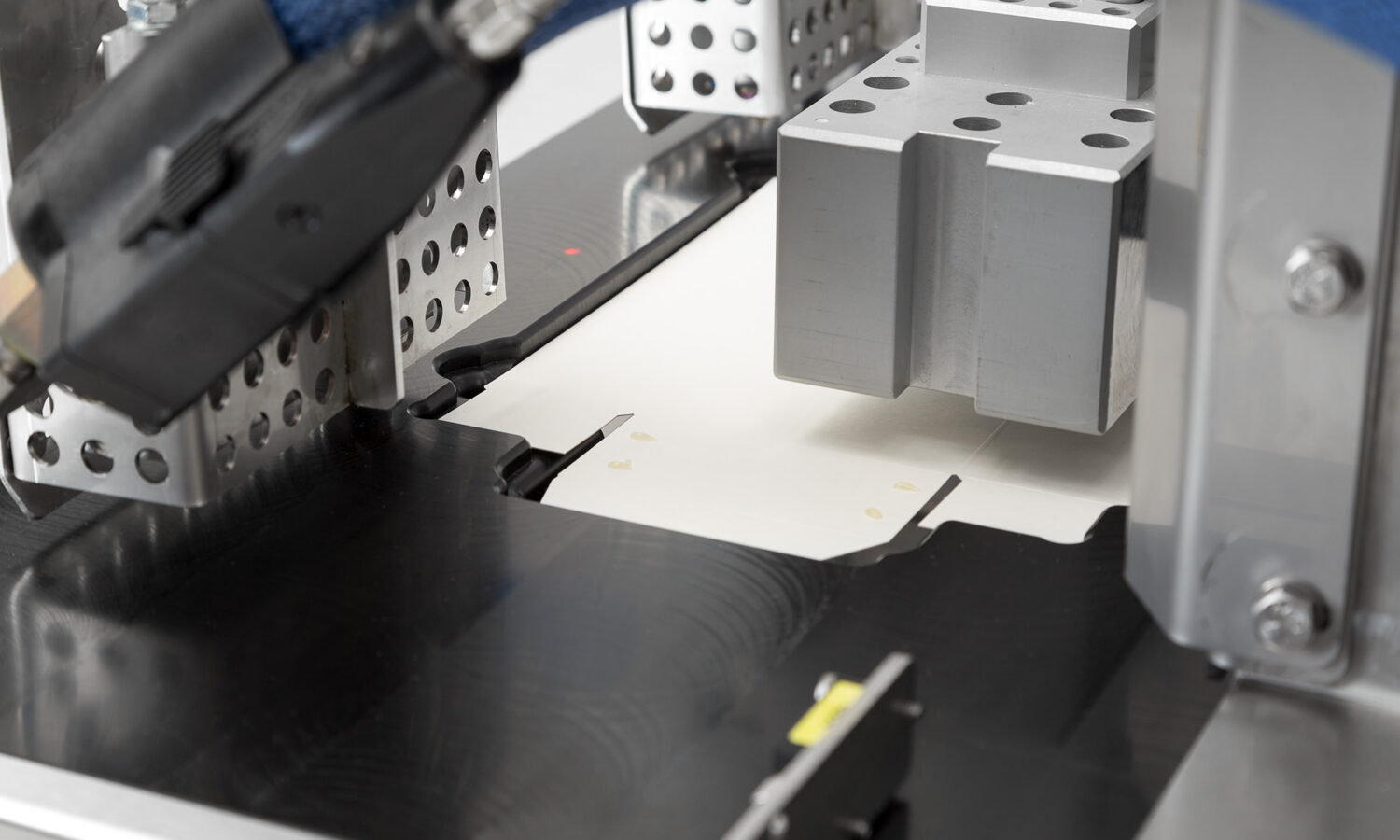

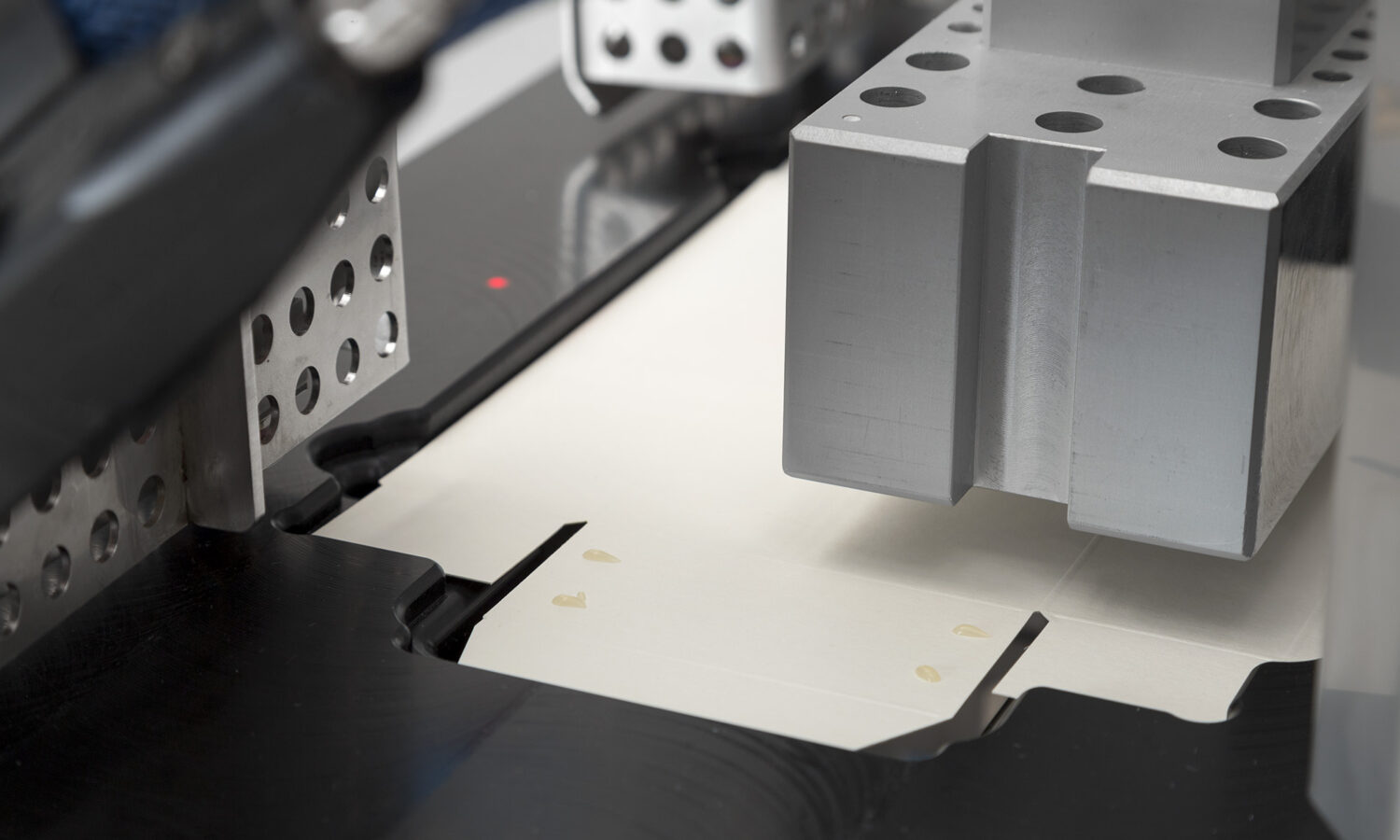

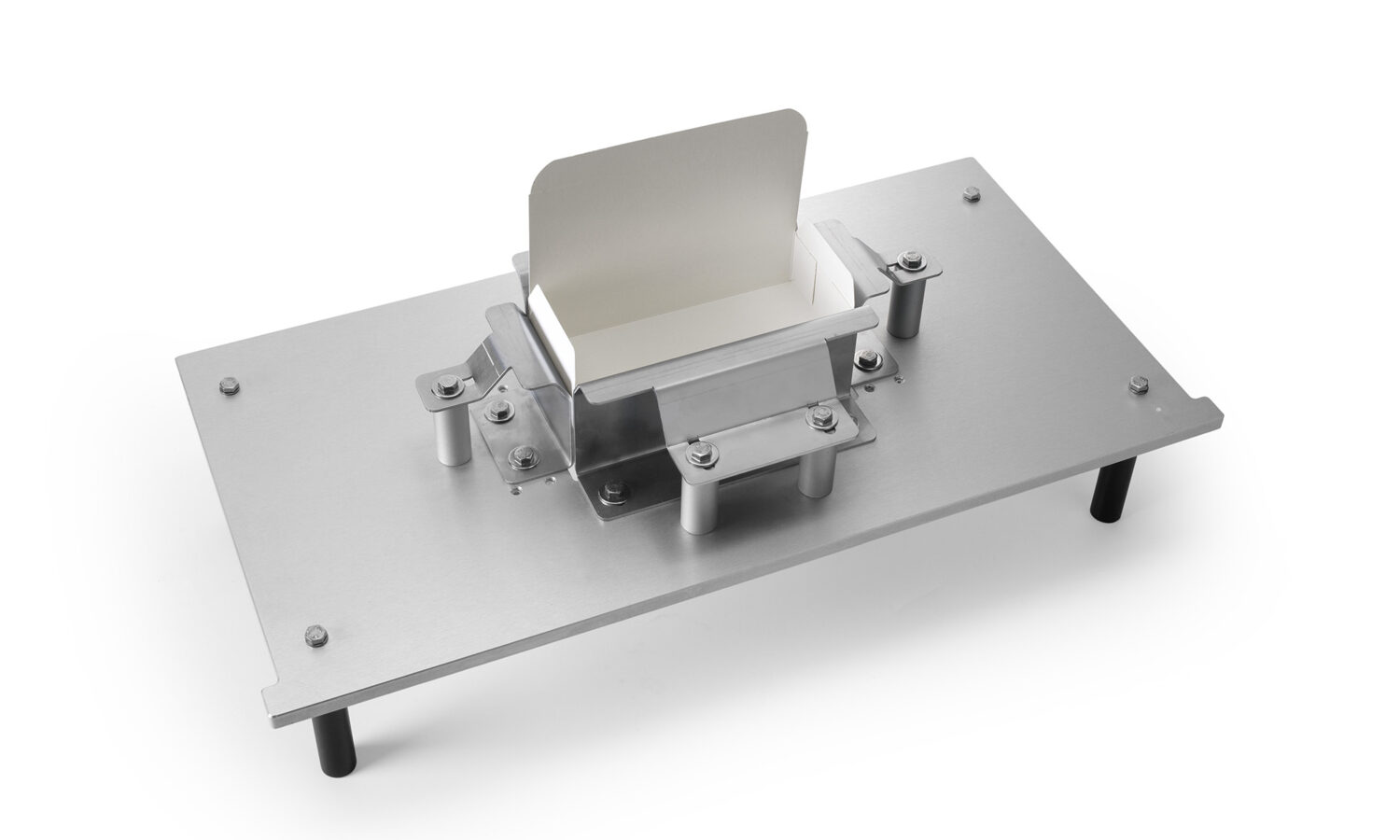

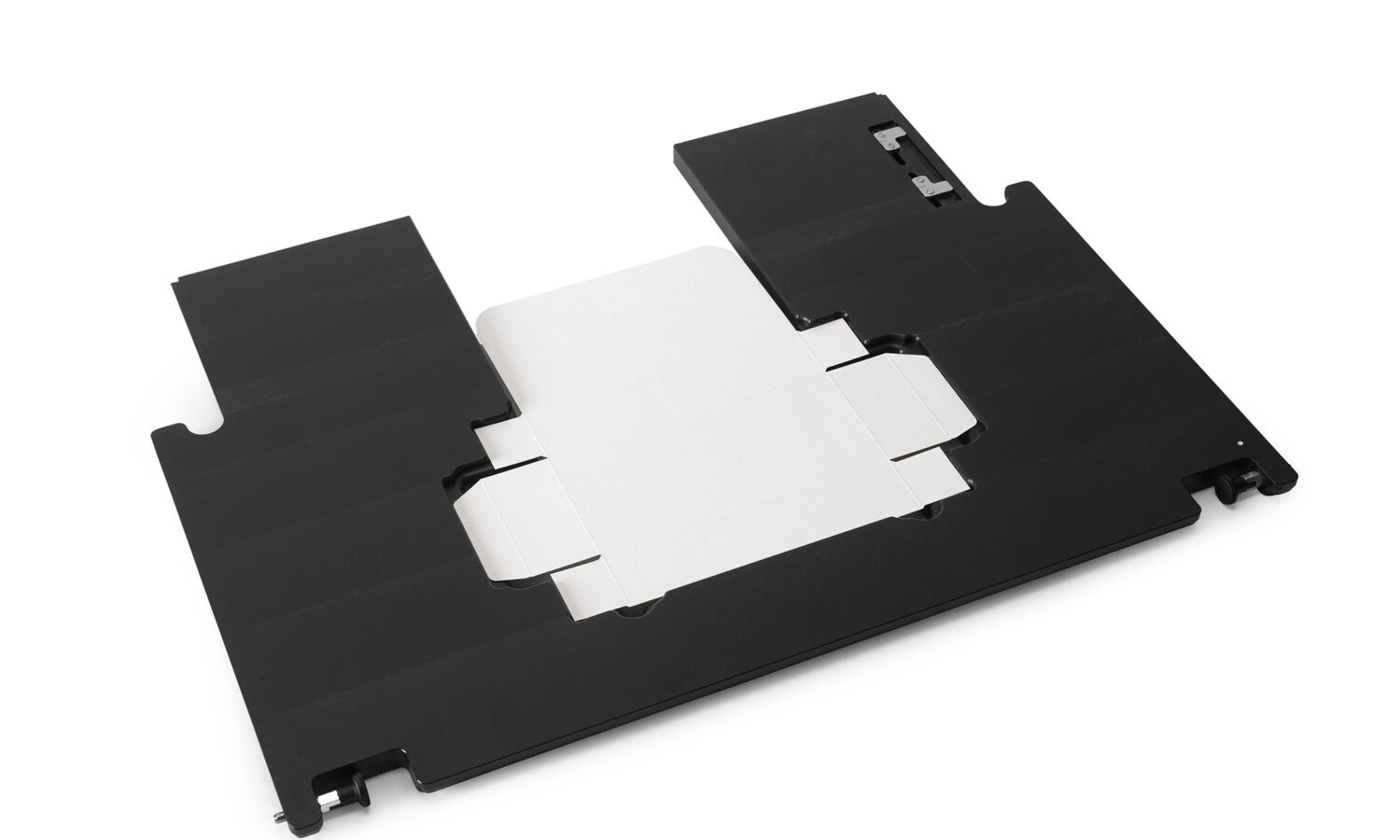

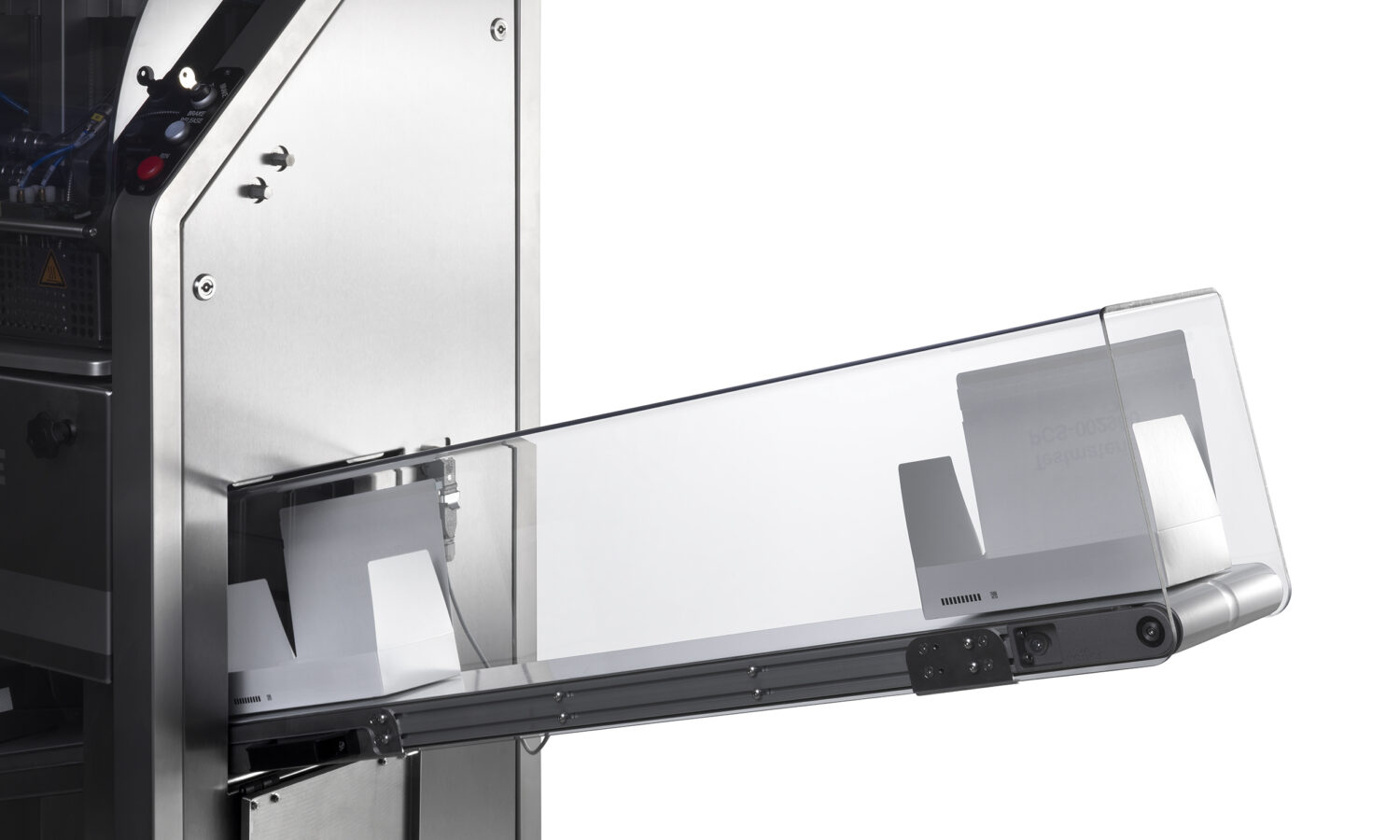

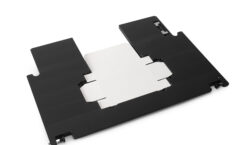

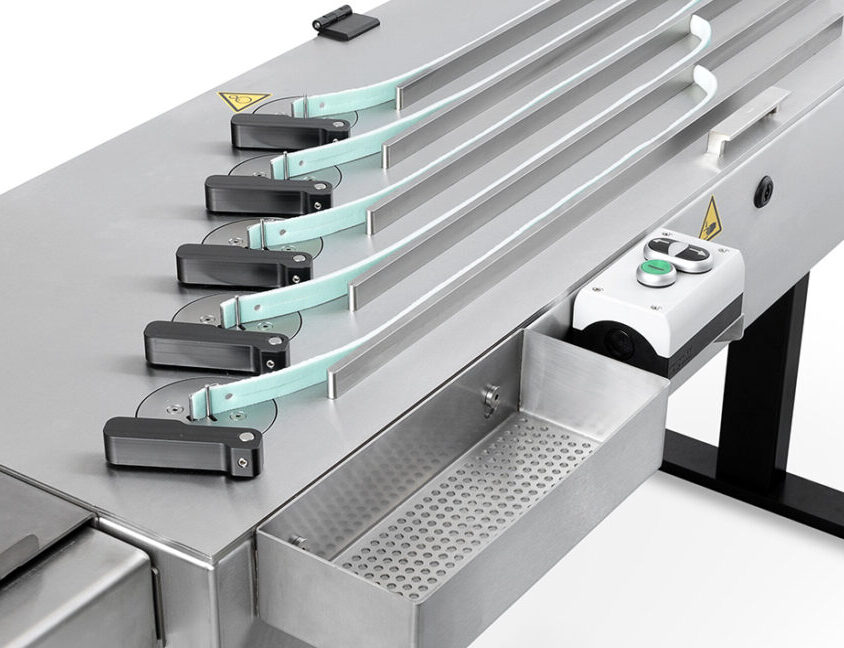

The machine has an automatic tray that positions the flat carboard and automatically applies glue. The cardboard is then placed on top of the folding tool and folded into the correct shape with the use of a pressing tool. The pressing tool, folding tool, and tray tool can be swapped out and are easy to position for a quick change-over. The optional conveyer belt ensures constant output, which can increase the capacity of the machine by 15%. It’s possible to modify the machine with features such as the automated feeding of boxes and the folding and gluing of inlays. Checking for barcodes or DataMatrixes through Vision Systems or a tooling cart for safe storage of interchangeable parts are also available.

The height of efficiency

The BOX-E excels in efficiency and offers companies considerable advantages in processing boxes. Its adaptability allows the machine to efficiently process multiple box sizes, enabling you to quickly and efficiently switch between different products and packing needs. The automated tray and precise glue application make for a smooth and error-free folding and gluing process. Constant monitoring with Vision Checks ensures you of a good production quality and consistency of the machine’s output.

Specifications

- Adaptable for different box sizes

- Efficiency and high production quality

- Suitable for high-mix, low-volume applications

- Automated tray for accurate cardboard positioning

- Automatic glue application on the right location

- Replaceable moulds (pressing tool, folding tool, tray tool) for flexibility

- Optional: conveyor belt for constant output and increased capacity

- Optional: automated cardboard infeed

- Optional: automatic folding and gluing function for inlays

- Optional: Vision System for barcode or DataMatrix monitoring

- Optional: tailor-made tooling cart for safe storage of interchangeable parts

Requesting assets

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields