Suitable for High Mix Low Volume

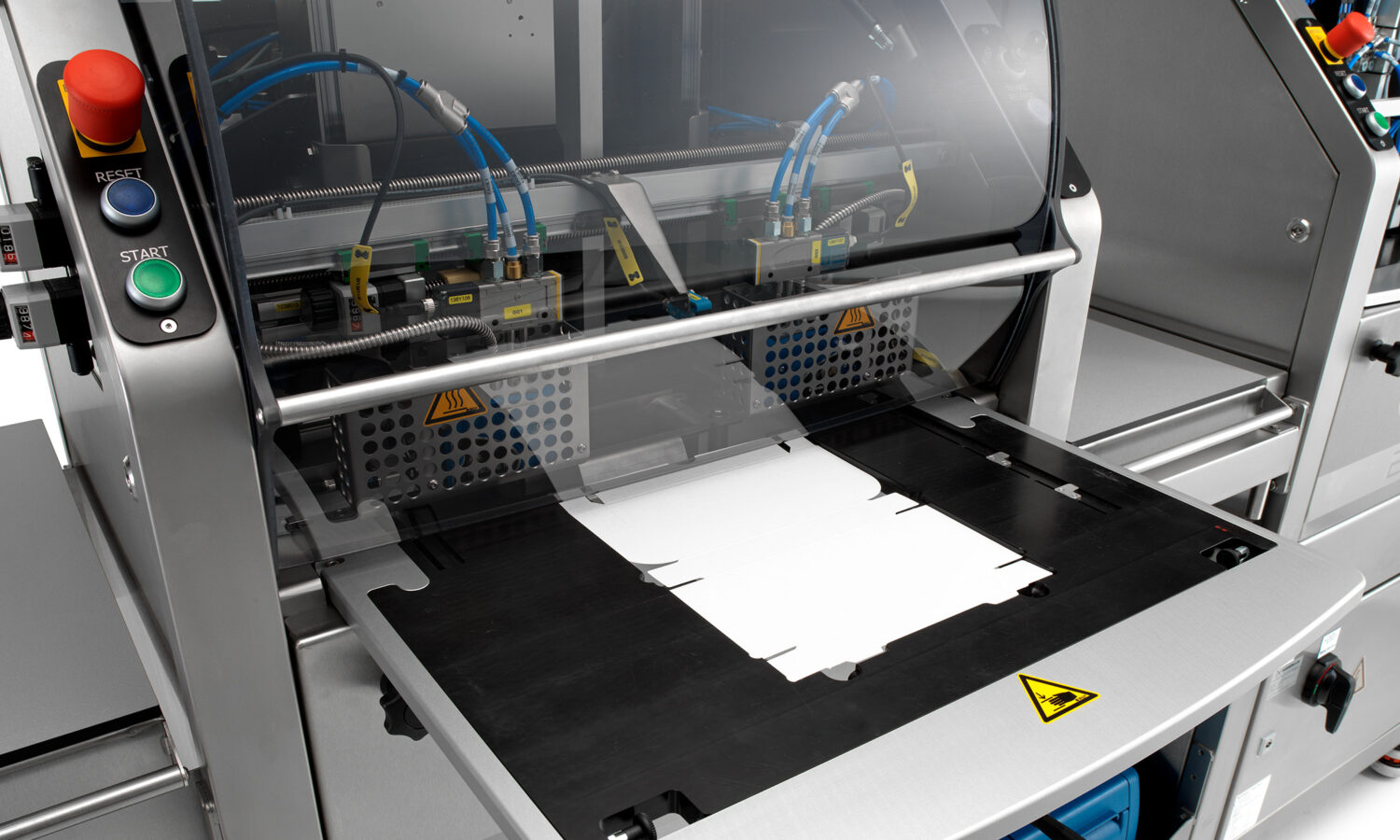

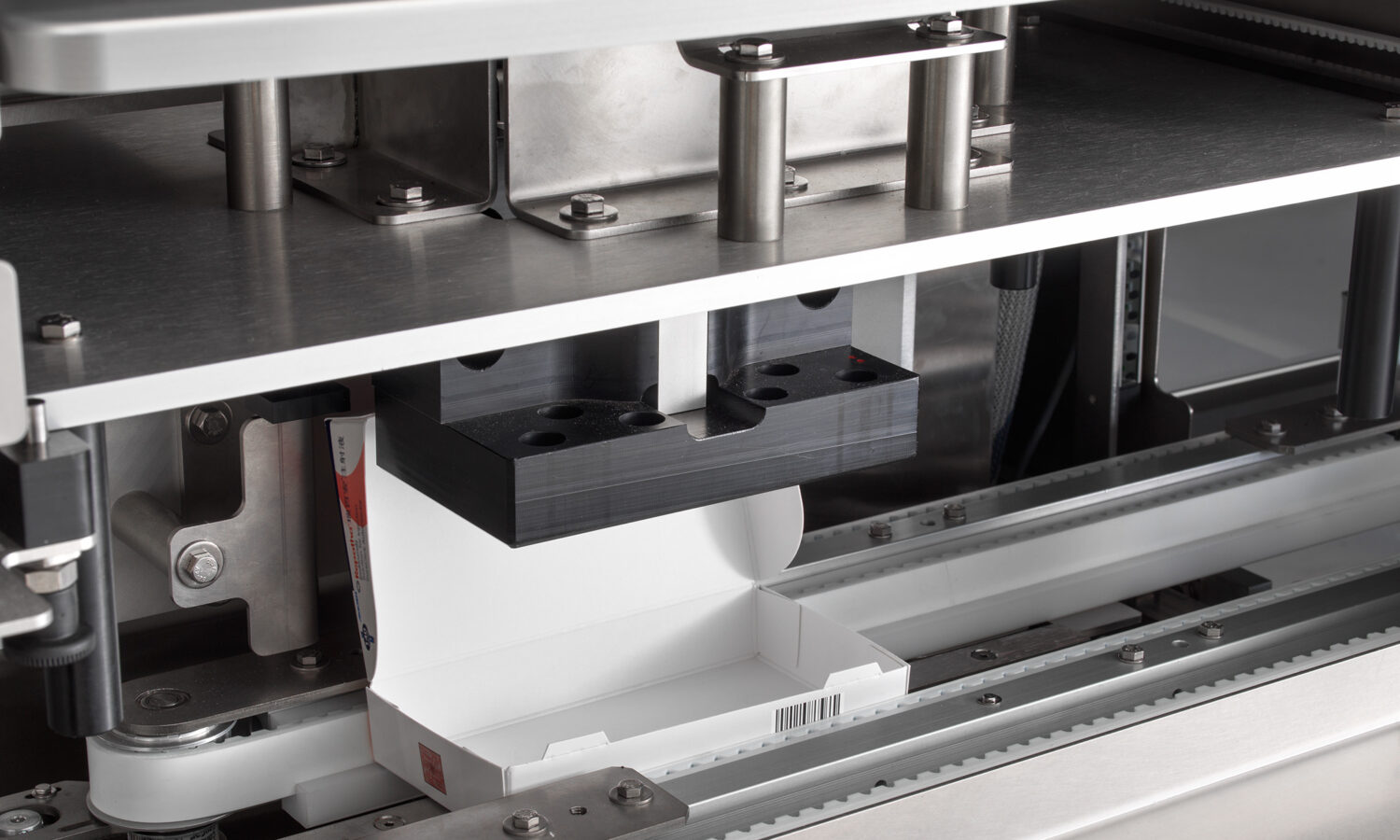

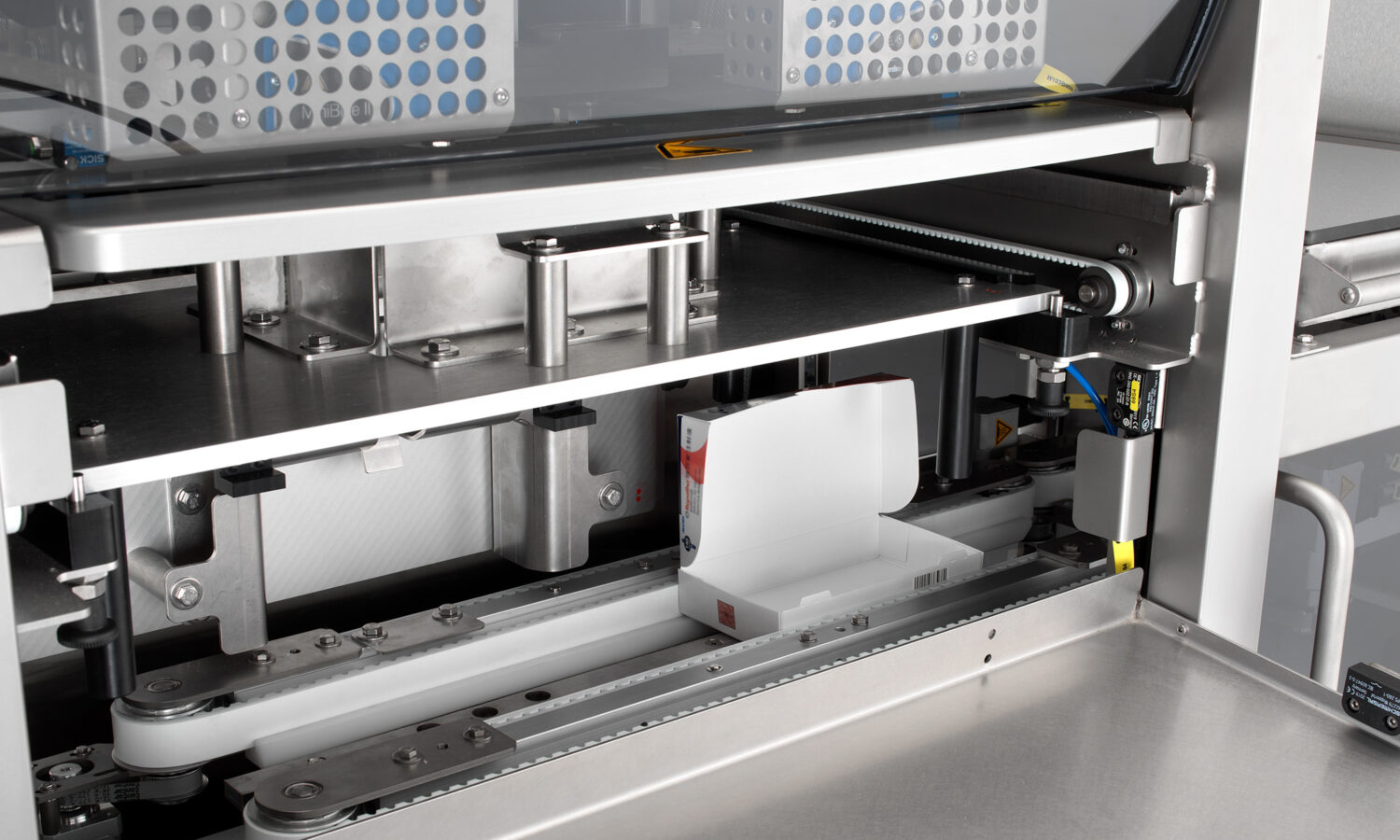

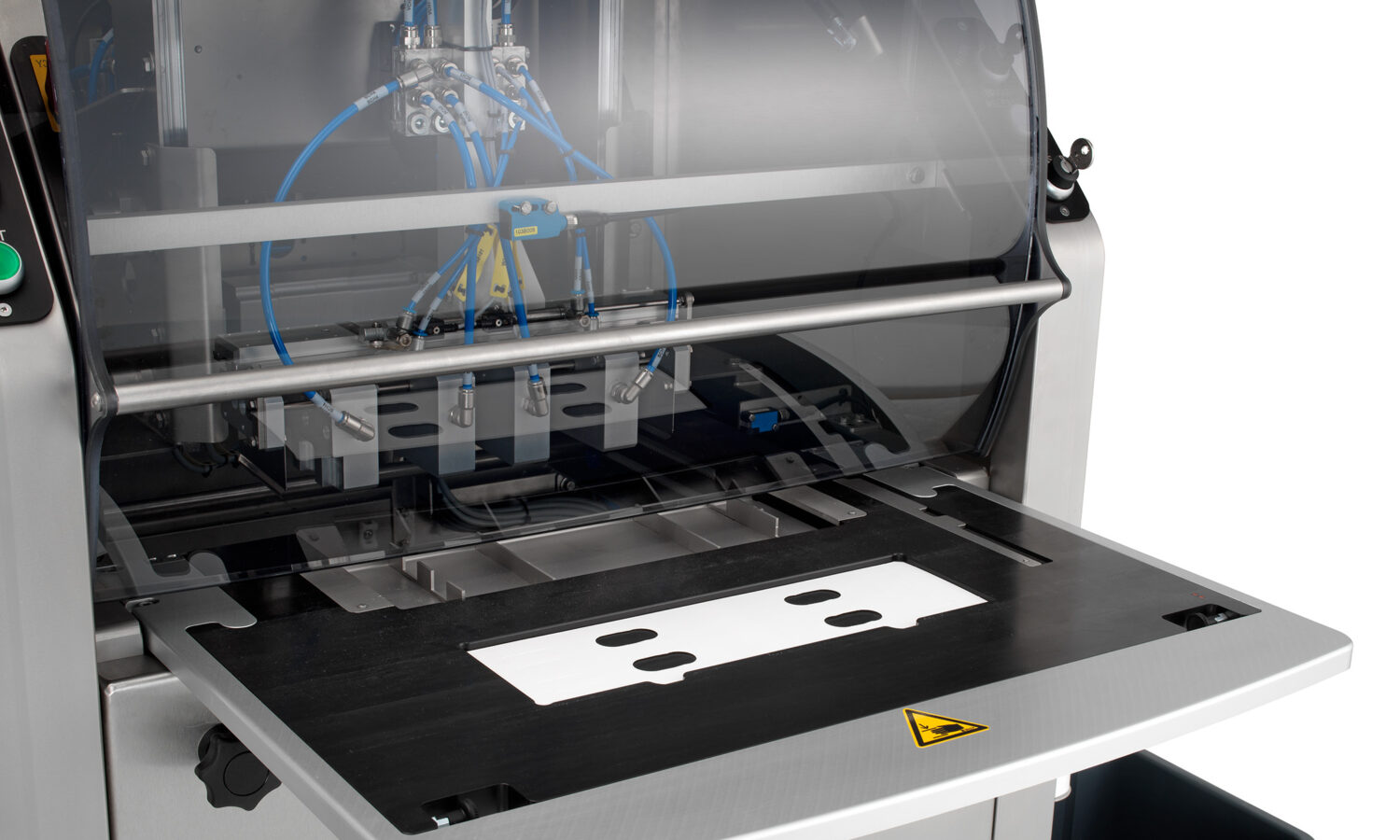

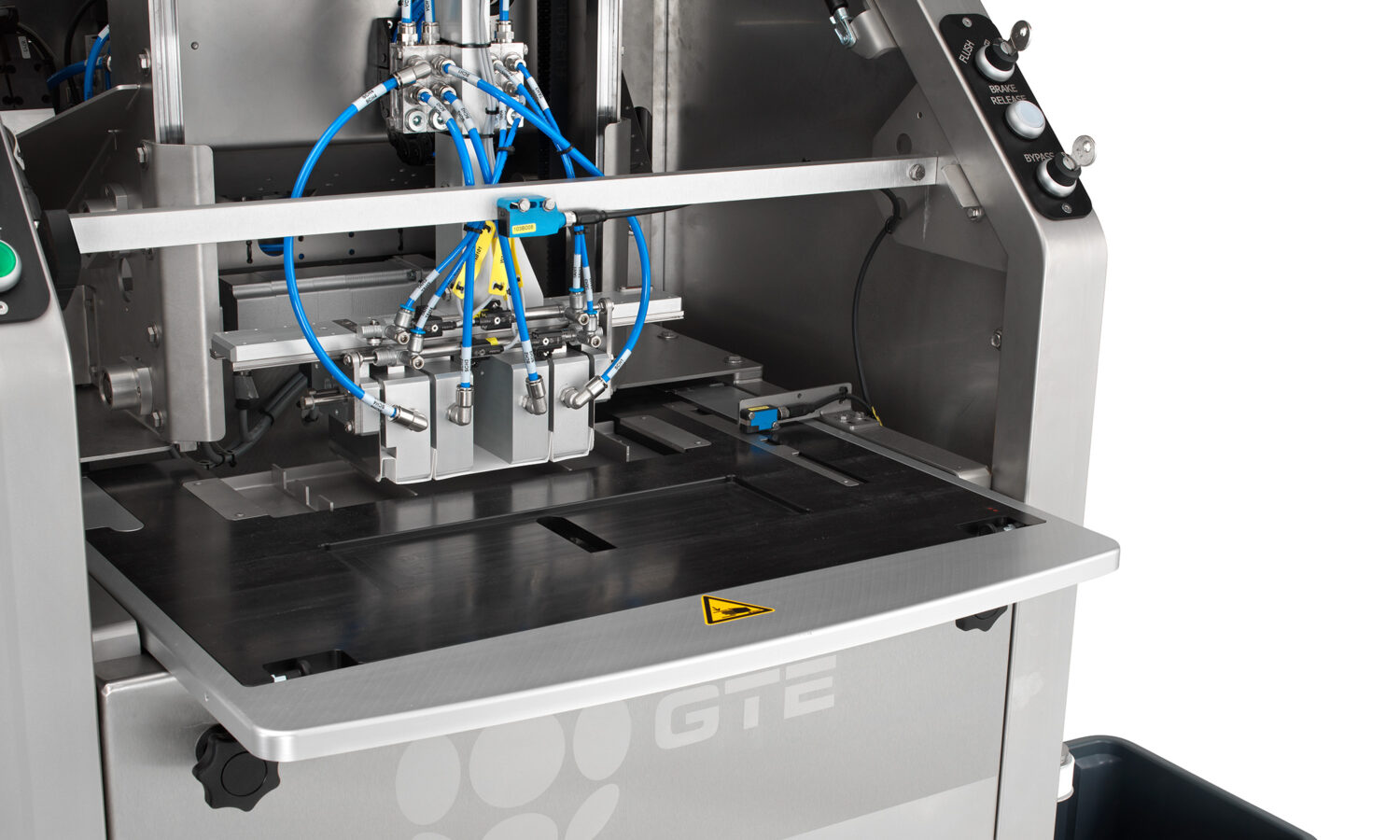

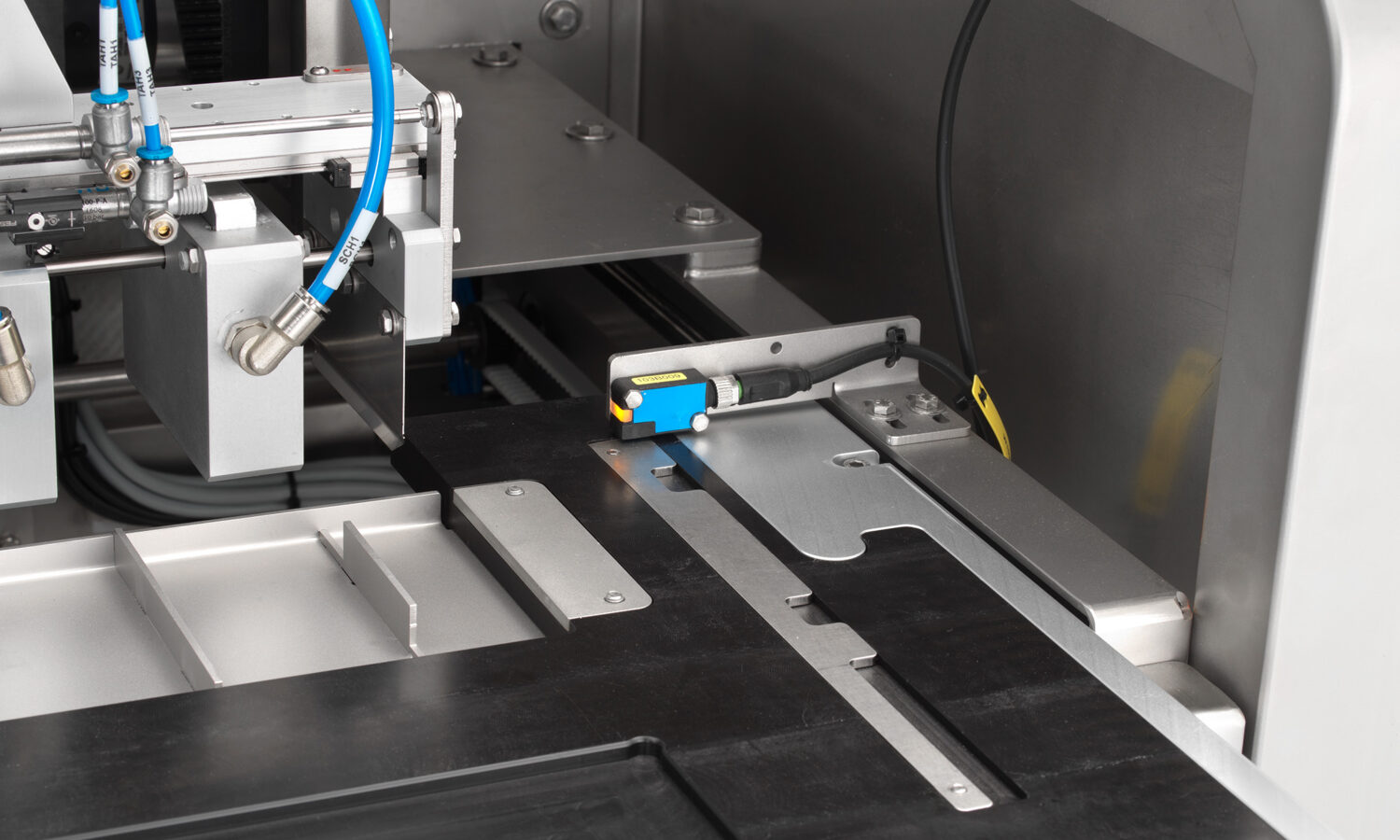

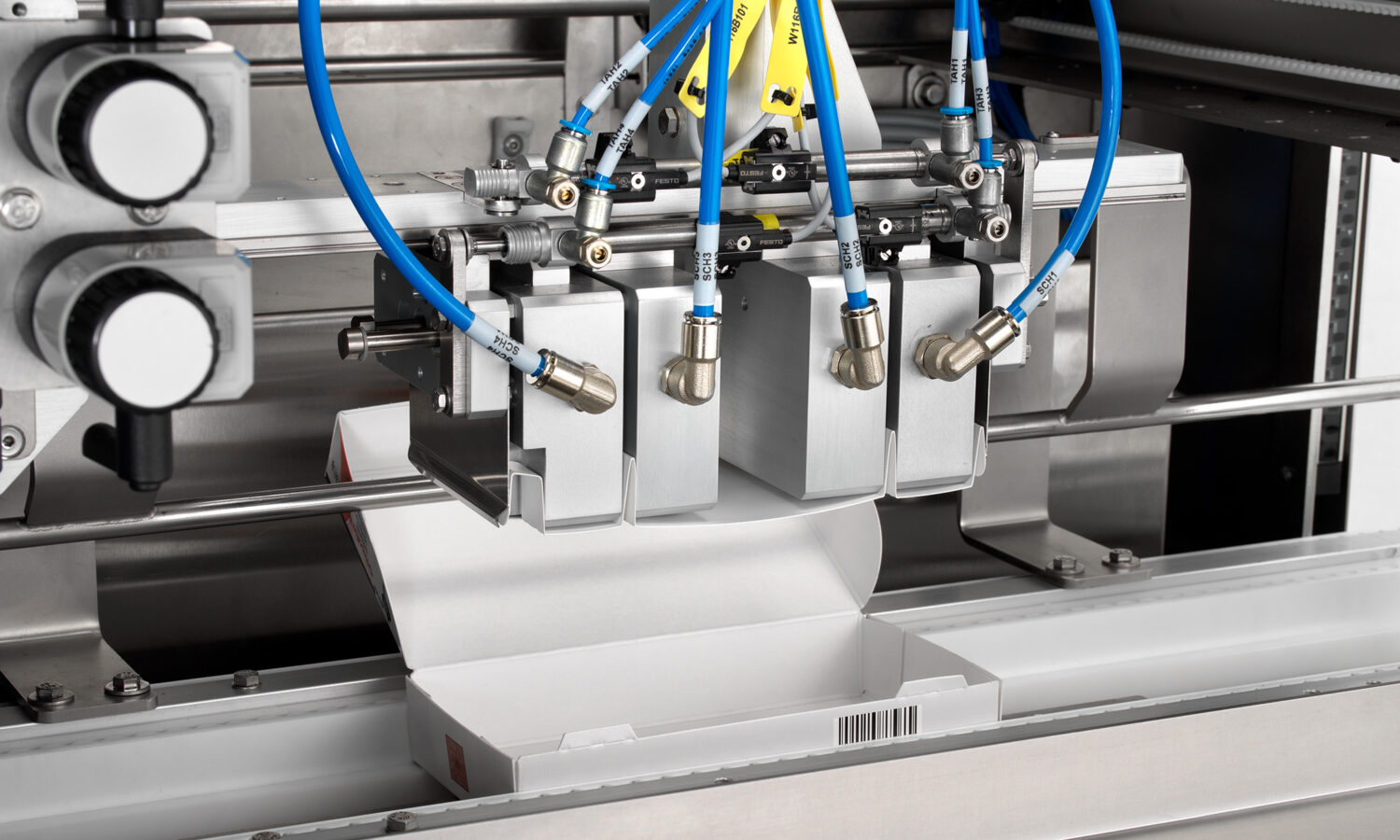

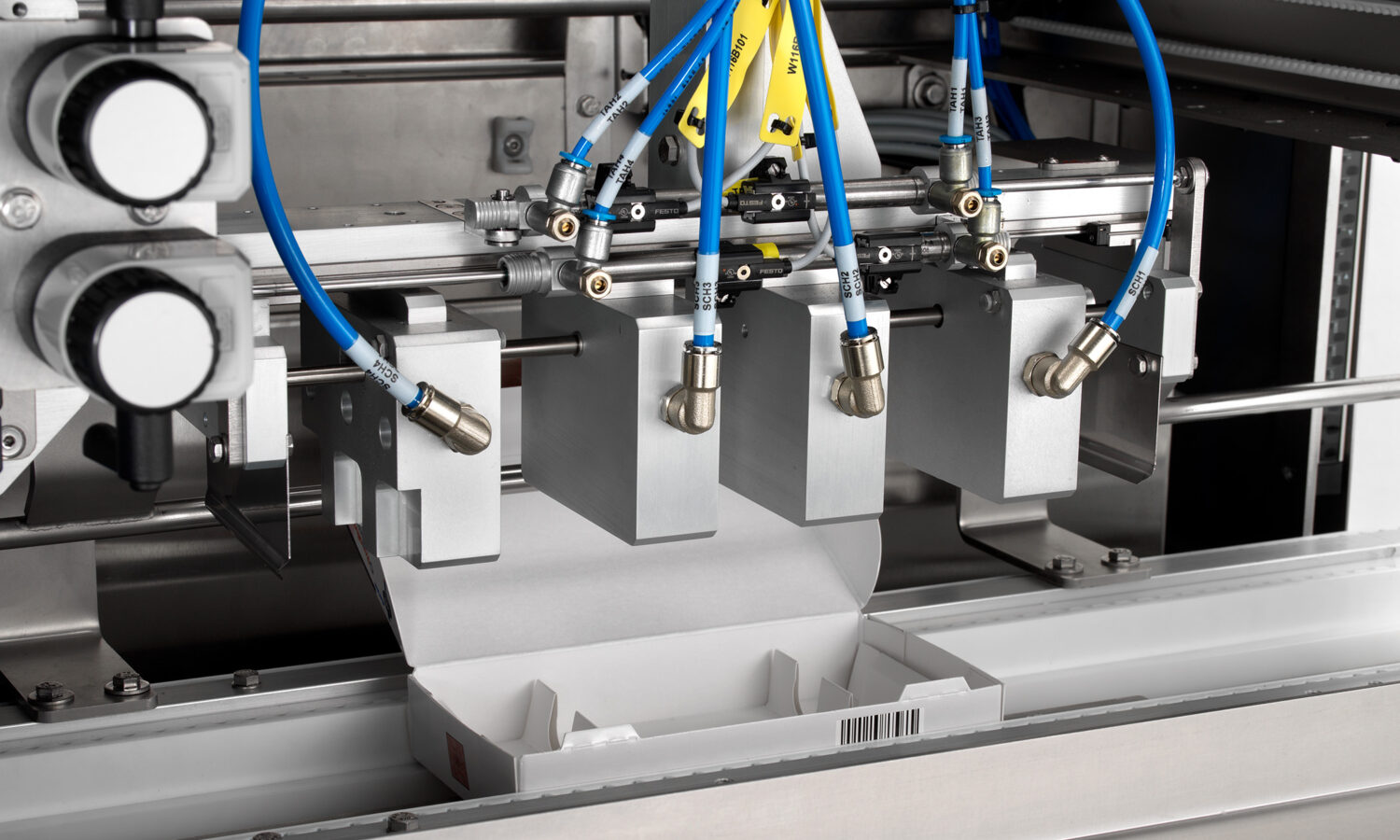

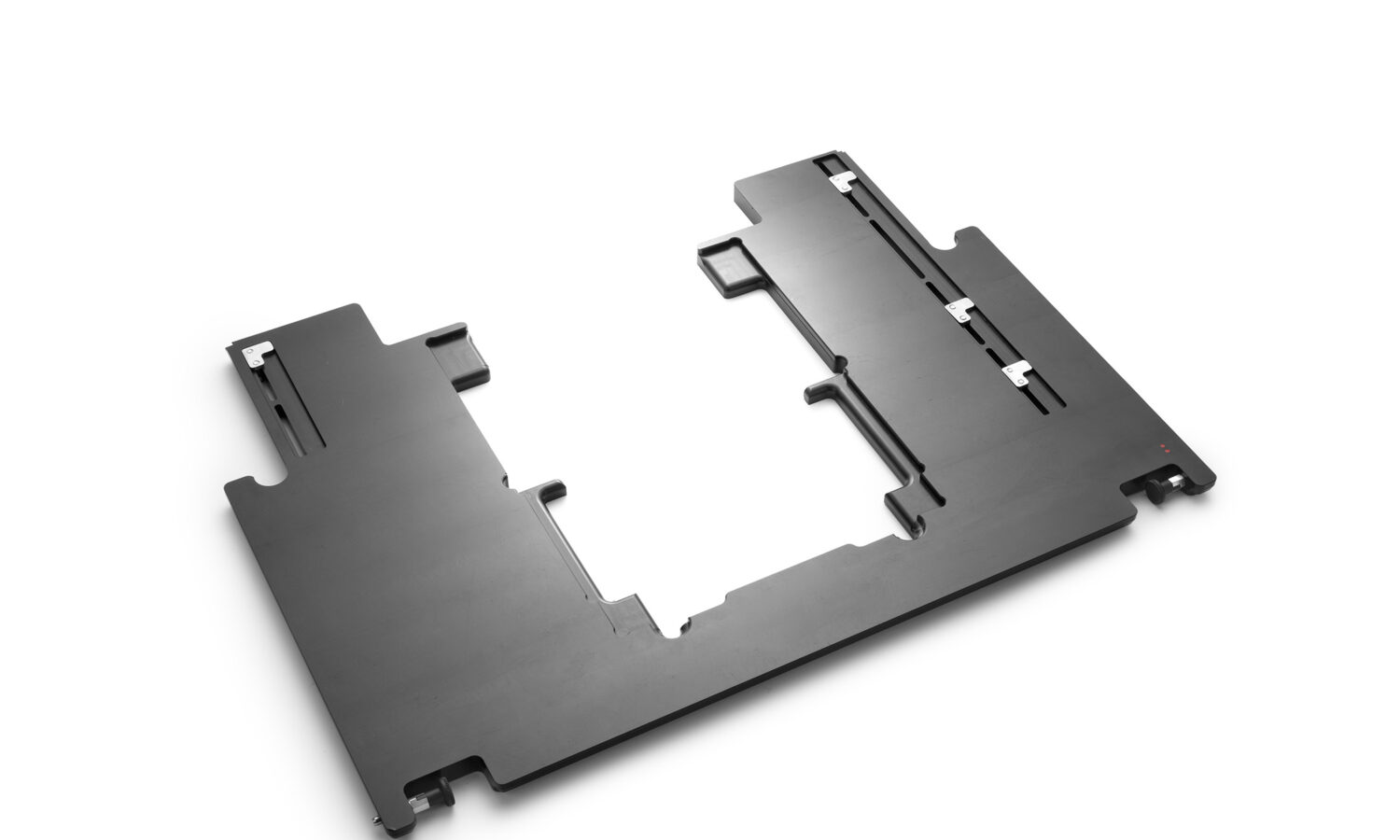

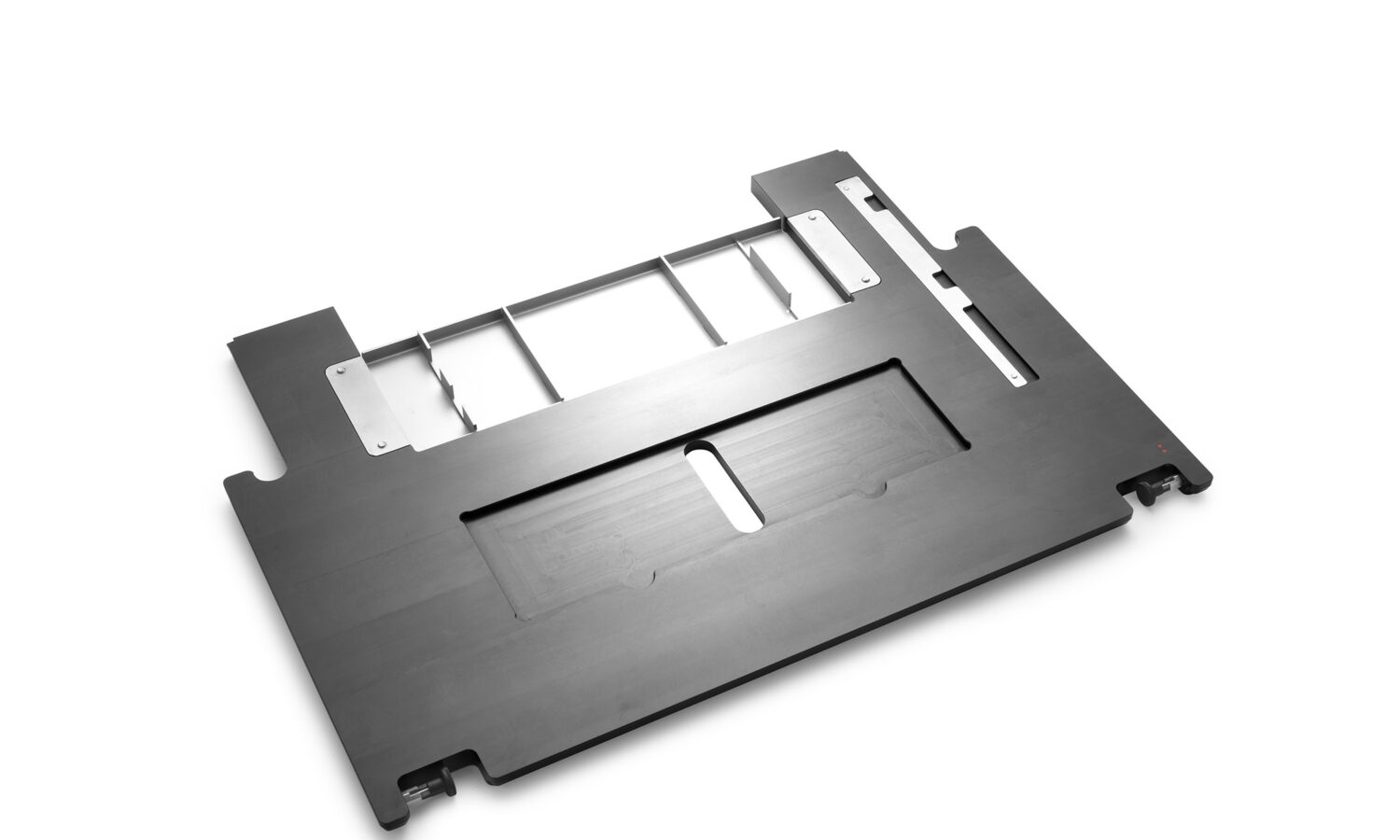

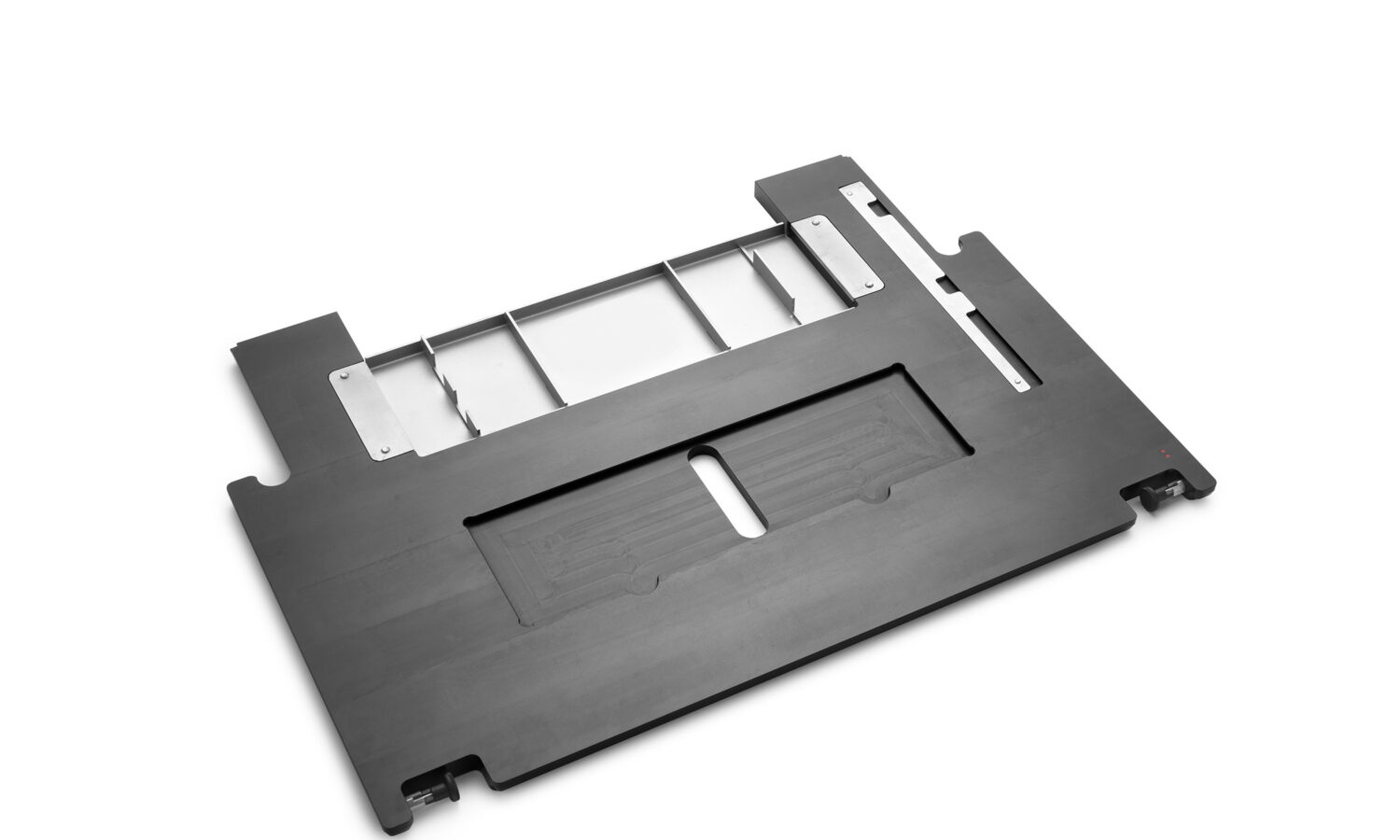

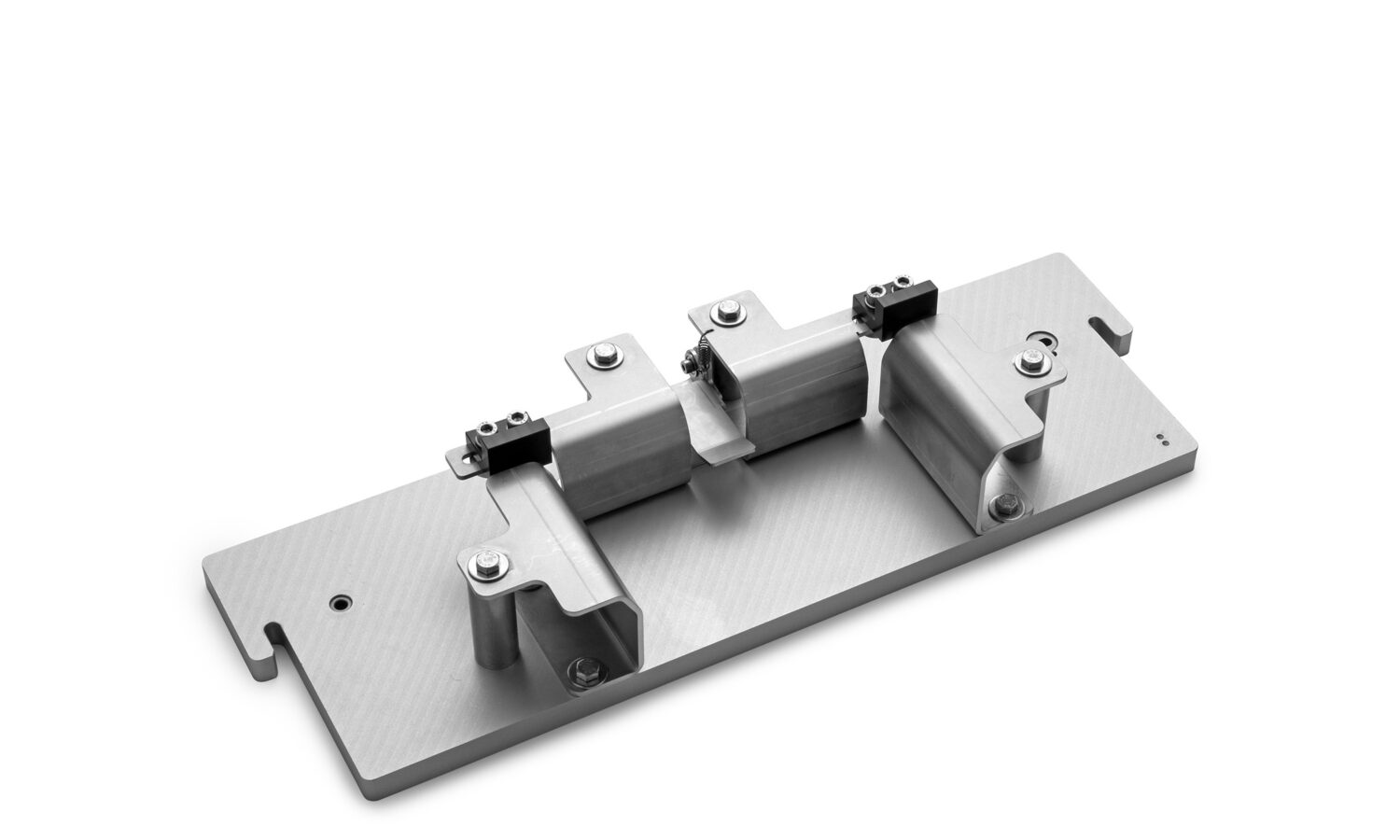

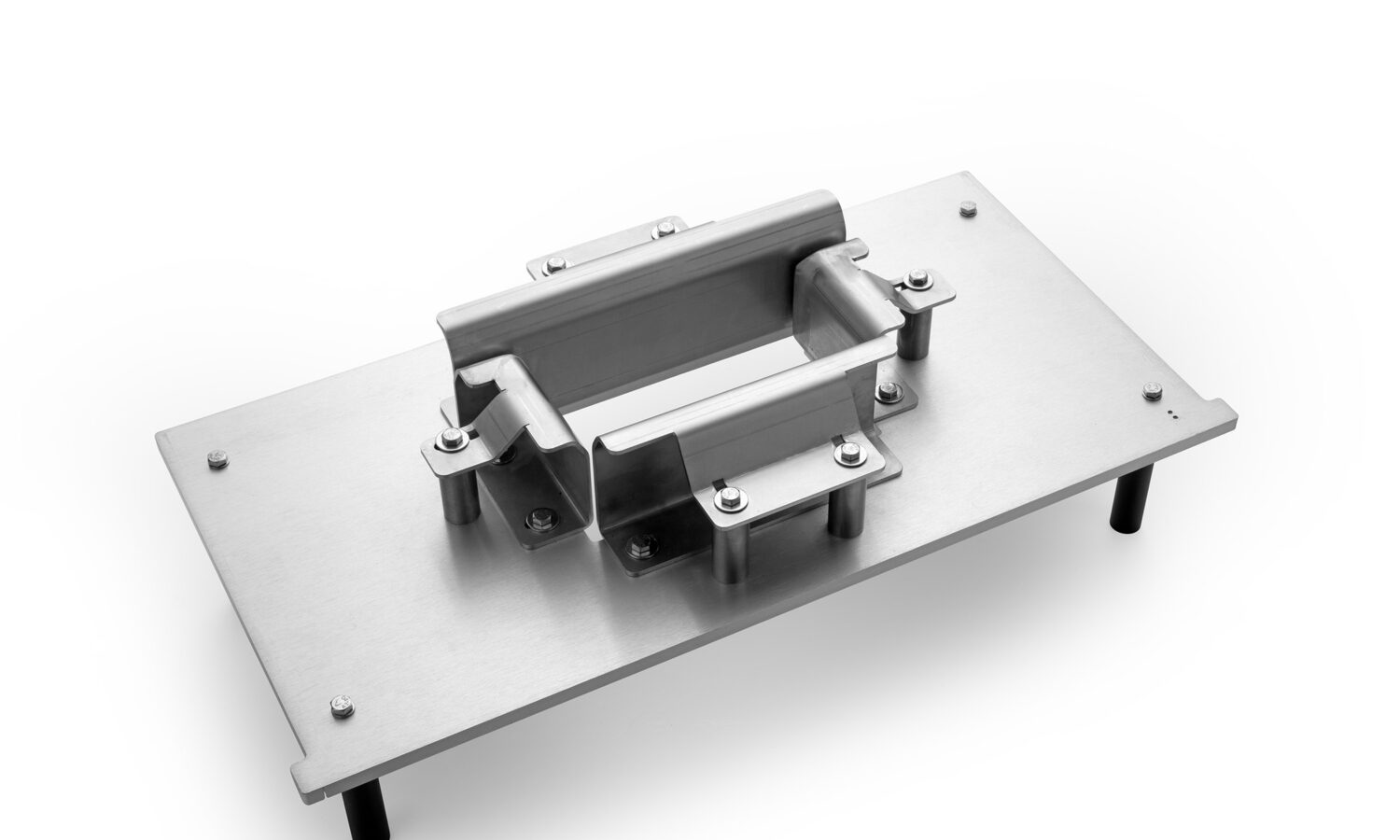

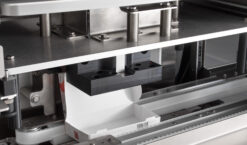

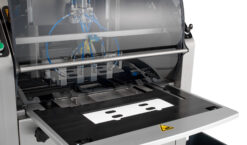

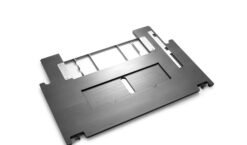

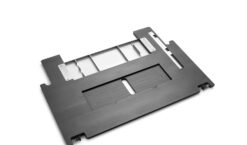

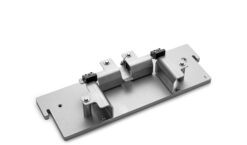

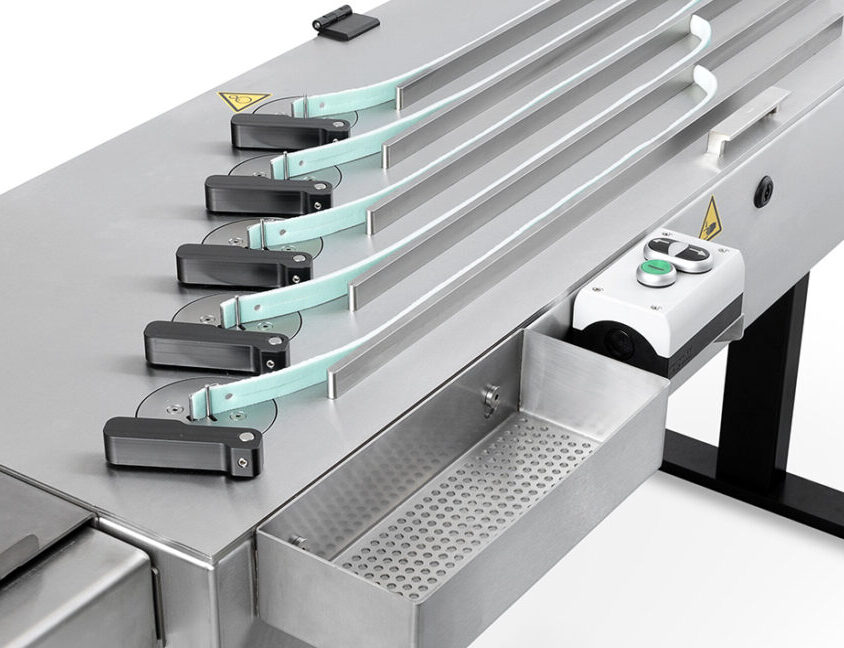

The automatic tray increases a production process’ efficiency. After the tray’s been closed, the machine places the flat cardboard above the folding tool and the pressing tool pushes the box around it so it’s pushed into the right shape and glued properly. The box is placed on a conveyor belt and moved to receive the cardboard insert. The inlay is manually placed in the cartoner and then automatically folded, glued and placed in the cardboard box. The lead time of a box with inlay is between 12 and 20 seconds. The lead time of a box without an insert is between 10 and 15 seconds. Both lead times depend on the size of the box and the speed of the operator. Additionally, the working height – the height from the floor to the top of the tray – is adjustable between 1.05 and 1.10 metres.

Specifications

- Compact design

- Tailored to your needs

- Short turn-around for different sizes

- Fast assembly time

- Ergonomic working

Requesting assets

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)